UTRGV / COLLEGE OF

ENGINEERING AND COMPUTER SCIENCE / MECHANICAL ENGINEERING DEPARTMENT

TEAM 9 - Design of a Mechanical Mesquite Bean Harvester

Design Process Page

|

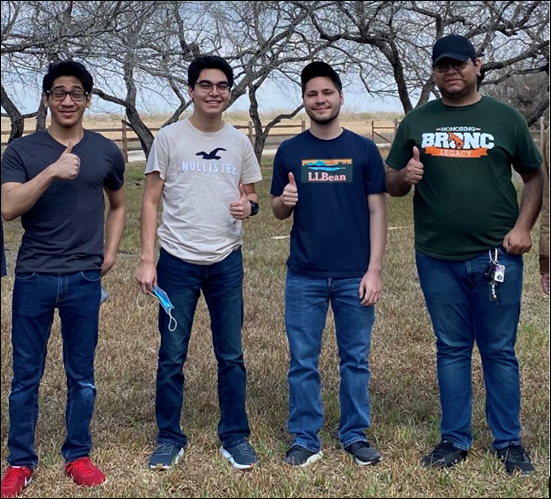

SDII Students (L-R) |

o Paul Silva o Miguel

Martinez o Benjamin

Huerta o Joshua

Sanchez

|

|

Faculty Advisors |

o Dr. Arturo Fuentes o Dr. Joanne Rampersad-Ammons

|

|

Course Instructors |

o

Dr. Noe

Vargas Hernandez o

Mr. Greg

Potter |

|

College of Business and Entrepreneurship Collaboration |

o

Dr. Sylvia

Robles (Instructor) o Daniel Castillo o Felipe Montemayor |

Back

to the PROJECT MAIN PAGE.

The Design Process involves several

critical steps that allow for a thorough analysis of the design. This is a non-linear,

iterative process; meaning there are constantly changes/revisions being made to

each step. During Senior Design, we followed a design process which facilitates

an effective and productive problem-solving process. A brief summary of each

step in the design process is listed below, followed by a detailed explanation

pertaining to each step.

Problem ID - Identify a valuable opportunity.

Problem Formulation - Clearly define the problem to solve.

Conceptual Design - Come up with ideas to solve the

problem.

Embodiment Design - Realize the idea.

Testing and Validation - Make sure it works.

The objective of the Problem ID

stage is to identify a valuable opportunity.

The challenge here is identifying a

real problem that the team can help solve. The first step is the brainstorming

phase, where many ideas are put forth and examined. Whether or not each of these

ideas have potential (value opportunity), the process of generating problem

ideas provides an incentive for the team to start thinking about how to solve them.

Once a value opportunity is identified, the next step is to elaborate why such

opportunity exists. This is done by putting together a value proposition, which

explains why the product would be valuable. A product opportunity gap is then

developed to detail how our product could solve the problem at hand (how it

works, technology used, etc.). In addition, a Value Opportunity Analysis is

conducted to evaluate how our proposed solution compares to products within the

current market.

Product

Opportunity Gap (POG)

Our preliminary idea is to utilize

the concept of a rotating unbalance to design a vibrating mechanical device that

exerts a range of driving frequencies equal to that of the natural frequency

range of the mesquite bean pods attached on tree branches. Because not all

mesquite bean pods have the same natural frequency (based on geometry, size,

density, etc.), the rotating unbalance will have to sweep through a range of

natural frequencies. The excitation of the mesquite bean pods will result in

resonance, thus causing the mesquite bean pods to fall from the branches with

ease. Because the proposed device is aimed at exciting the mesquite bean pods

themselves, the mechanism will be mounted on a tree branch, after which the

forced vibrations will propagate through the branch and onto the hanging bean

pods. This approach provides a considerable advantage over hand-picking each

mesquite seed pod individually since it's able to discharge dozens of mesquite

beans at a time, requires relatively no manual labor/input, and eliminates the

possibility of someone getting injured by the long thorns on mesquite tree branches.

Expediting the harvesting process allows for a massive yield of mesquite beans

and therefore enables the business at hand to expand towards mass production of

mesquite bean products.

|

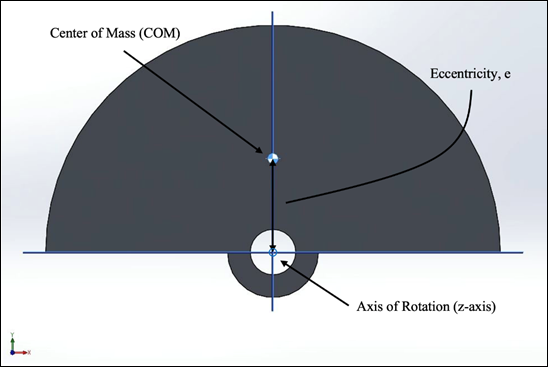

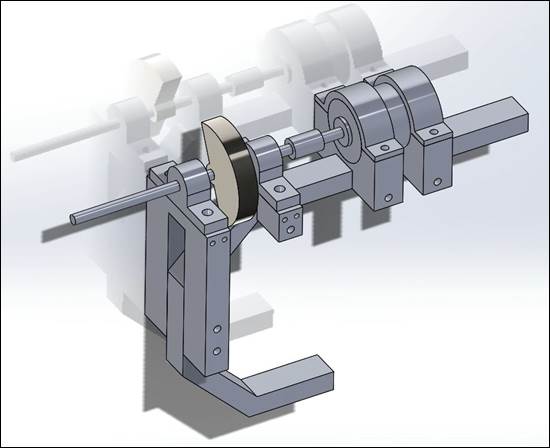

Figure 1 - Rotating Unbalance

Mechanism Sketch |

Value

Opportunity Analysis (VOA)

For the selected POG we created VOA

charts to evaluate our proposed solution to that of current mesquite bean

harvesting methods as well as similar devices currently in the market. These

charts give us an idea of how much of an improvement a mechanical harvester is

over hand picking, in addition to how it compares to that of similar devices.

Team 9 - Ripple Effect

|

ATTRIBUTES |

LOW |

MED |

HIGH |

|

Affordability |

|

|

x |

|

Sustainability |

|

|

x |

|

Quality |

|

|

x |

|

User Friendly |

|

|

x |

|

Aesthetics |

|

x |

|

|

Efficiency |

|

|

x |

|

Safety |

|

|

x |

Hand Picking (Current Method)

|

ATTRIBUTES |

LOW |

MED |

HIGH |

|

Affordability |

|

|

x |

|

Sustainability |

|

|

x |

|

Quality |

|

|

x |

|

User Friendly |

|

|

x |

|

Aesthetics |

|

x |

|

|

Efficiency |

x |

|

|

|

Safety |

x |

|

|

|

Figure 2 - Cappadona Family Hand-picking Mesquite Beans |

Kadioglu

EMR400 Branch Shaker

|

ATTRIBUTES |

LOW |

MED |

HIGH |

|

Affordability |

|

x |

|

|

Sustainability |

|

|

x |

|

Quality |

|

x |

|

|

User Friendly |

|

x |

|

|

Aesthetics |

|

x |

|

|

Efficiency |

|

x |

|

|

Safety |

|

|

x |

|

Figure 3 - Kadioglu EMR400 Branch

Shaker |

Yuki Farm Harvesting Machine Orchard

Fruit Tree Shaker

|

ATTRIBUTES |

LOW |

MED |

HIGH |

|

Affordability |

|

|

x |

|

Sustainability |

|

|

x |

|

Quality |

|

x |

|

|

User Friendly |

|

x |

|

|

Aesthetics |

|

x |

|

|

Efficiency |

|

x |

|

|

Safety |

|

|

x |

|

Figure

4 - Yuki Farm Harvesting Machine Orchard Fruit Tree Shaker |

FINAL

PROBLEM STATEMENT

There is a direct need for a mesquite

bean harvester capable of expediting the mesquite bean harvesting process in a

safe and efficient manner.

The objective of the Problem

Formulation stage is to clearly define the problem to solve.

This section involves getting a

better understanding of the problem we are trying to solve by conducting

research on relevant topics, analyzing the performance of existing products, identifying

the main user of our solution (as well as the value for the user), determining

initial customer segment, and generating a design specification (list of

requirements). These subtasks within problem formulation will help the team get

a clear understanding of the problem to solve.

BACKGROUND

RESEARCH

To better understand the context of

the problem to solve, we conducted Background Research on the following topics:

o

Mesquite

Trees

o

Mesquite

Beans

o

Frequency

Response of Trees

o

Mechanical

Properties of Trees

o

Mechanical

Stability of Trees

o

Analysis

Methods

o

Vibrating

Machinery (Rotating Unbalance)

o

FEA

Modeling and Material and Geometric Properties (Numerical Methods)

o

Mechanical

Harvesting

Figure 5 - Mesquite Tree at Park

Figure 6 - Branch Complexity

Figures 7 & 8 - Mesquite Beans on Branch

Figure 9 - Fallen Mesquite Bean

COMPETITIVE

PRODUCTS

To avoid "reinventing the wheel",

we looked at existing solutions and competitive products.

Listed

below are the closest competitors for the task at hand. Although there are no

dedicated mesquite tree harvesting devices, there are devices which are used to

harvest other products in a similar manner.

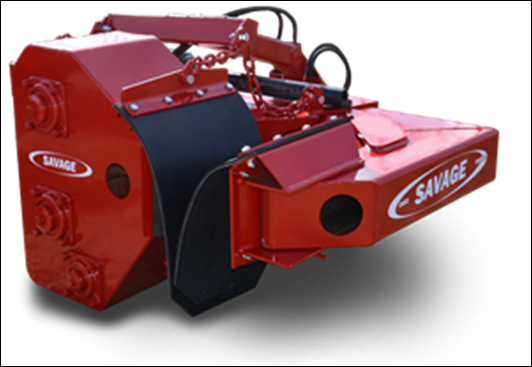

1. Tractor Attachment

Savage Shaker

Figure

10 - Savage Shaker

Click HERE to View Product Website.

Description -

This pecan tree shaker was the first piece of machinery developed at Savage, as

well as the first of its kind for the nut-harvesting industry. Savage Shakers

have evolved into finely crafted, rugged machines, and they now help growers

get the job done on many parts of the globe. The Savage shaker can shake almost

any tree. The machine is available in various sizes, with each model capable of

shaking a wide range of tree sizes.

Advantages

- The

shaker attachment is ruggedly built. Savage Shakers feature heavily braced and

reinforced clamp arms; easily removed bearings and simple access to shaking

components; oversized adjustable drive chains; and easily changed tree pads.

Disadvantages -

The savage shaker is a tractor attachment, meaning it requires a tractor with a

PTO (Power take-off) to function. It also requires a certain amount of PTO or

HP (Horsepower) to produce the proper vibration, depending on the size of the

tree. This can be a problem if one's tractor does not generate enough power for

the shaker attachment.

2. Shaker & Collector

MultiOne Tree Shaker &

Collector

Figure

11 - MultiOne Tree Shaker & Collector

Click HERE to View Product

Website.

Description -

The tree shaker attachment incorporates the most advanced harvest technology

for olives, almonds, nuts, pistachio, etc. The shaker requires a minimum

distance of 70 cm (27 in) from the soil to the foliage. The adjustable

vibration frequency maximizes the effect on the fruit, avoiding low frequency

vibrations on the trunk. The hydraulically controlled collector has a diameter

of 5 m (16.4 ft), capturing fruit from large trees and is equipped with a

hydraulically opening hatch through which is possible to unload the product

collected directly on trucks or trailers. The shaker vibrating head is powered

by a compact hydraulic motor and it is tiltable to the right and to the left (�

40�).

Advantages

- Total

control of vibration frequency allows for shaking different trees at different

frequencies. Very efficient machine. Depending on ground conditions, as many as

40 to 60 trees can be processed per hour. Has a wide collector to catch fruit

from large trees. Operates on trees with wide trunks. Can adjust vibrating head

to shake at different angles. Shaker's controls are located near the operator's

seat and controls all movements and vibration frequency. Combines shaking

device with collection system.

Disadvantages -

Adjustable vibration frequency has a limit of 40 Hz. Tree Shaker and Collector

attachment requires MultiOne Mini Loader Vehicle. Tree Shaker & Collector

is not universal (not compatible with other tractors).

3. Mobile

Shaker

Kadioglu

EMR400 Branch Shaker Harvesting Machine

Figure

12 - Kadioglu EMR 400 Branch Shaker Harvesting Machine

Click HERE to View Product

Website.

Description -

The Kaidoglu EMR400 features a handheld hook-shaped gripping mechanism which

delivers high frequency vibrations to cause fruit to fall. It utilizes a

gasoline engine with 2.6 horsepower. The motor is worn on the back of the user

and has a mass of about 9.5 kg (about 20 pounds) while the hook mechanism has a

mass of 2.5 kg (about 5.5 pounds). This device is intended for use on walnut

tree branches with height up to 4 meters and thickness of 3 cm. In case of

failure, the device is modular, and parts can be replaced.

Advantages

- Engine

can be worn as a backpack which makes the device very mobile (Motor weight: 9.5

kg). Can be used on almost any type of tree. Does not require a large power

input. Gasoline motor has high price/performance ratio. Long arm can reach

branches that are high up in trees. Relatively easy to use (trigger activated).

Disadvantages -

For very large, tall trees, extender arm may not be able to reach branches that

are very high up. Grip width is not adjustable. Can only grab onto branches

that are 3 inches thick or less. Unbale to adjust frequency of vibration.

4. Shaker Vehicle

OMC Shockwave Sprint VI

Figure

13 - OMC Shockwave Spring VI

Click HERE to View Product

Website.

Description -

The latest version of OMC's Shockwave Sprint tree shaker makes life easier by

boosting the harvest efficiency for farmers growing almonds, walnuts, or young

pecans. The key to the Sprint's high performance is its side-mounted shaker

which allows the operator to glide down the row and shake up to 7 trees per

minute. The all-new R-7 Magnum shaker head with 24-inch oval pads and automatic

sling lubrication is standard, providing powerful shaking performance in a

compact package that effortlessly moves through dense plantings. Movement is

provided by a hydrostatic drive with a 19-1 ratio, with a 24-1 ratio available

as a no-cost option. LED night lights illuminate the front, side and rear of

the vehicle, while a color monitor provides crucial information and settings

inside. Heating and air-conditioning are standard, for more comfortable and

productive days in the field.

Advantages

- No

attachments needed. Shaking mechanism is integrated into vehicle. Contains a

comfortable cabin with air-conditioning and heater. Equipped LED lights allow

for nighttime harvesting. Shaker is mounted on side to allow clear visibility

for driver. The side-mounting for efficient harvesting since driver can simply

drive up a row, shake each tree, without having to maneuver from side to side.

New shaking technology provides powerful shaking.

Disadvantages -

Heavy duty vehicle (large in size). Almost 19 feet in length and 12 feet wide

(with shaker head retracted). Requires vehicle maintenance.

5.

Collector

The

Original Fruit Collector

Figure

14 - The Original Fruit Collector

Click HERE to View Product

Website.

Description -

The Original Fruit Collector is a harvesting net designed to catch fruit fallen

from trees while protecting the fruit from dirt and bugs. It is advertised to

softly catch fruit from all fruit trees without bruising the fruit, including

apples, cherries, and others. The mesh design allows water and air to travel

through while keeping the fruit from rolling out of the enclosed area, thus

keeping the grass healthy. It is available in different sizes to suit

individual needs. It requires assembly from the user.

Advantages

- Rapid

set up can be achieved in a few minutes. Can be affixed to a pole or similar

structure instead of a tree if desired. Polyester fiber material is durable and

machine washable. Can work passively, the net will catch fruit if the tree is shaken

or if fruit falls naturally.

Disadvantages -

The collector is set up low to the ground, potentially creating difficulties if

the user wishes to manually shake the tree. Once set up, the fruit collector is

designed to stay in its place for long periods of time. If the user has

multiple trees to harvest from, they will need to purchase multiple collectors

or manually move it from tree to tree.

USER

RESEARCH

Understanding the user wants and

needs is key for the design of a valuable product. We applied a variety of User

Research techniques for that purpose.

In

this case, our main user will be farmers with medium-sized ranches in Texas who

harvest mesquite beans for mass production of a product. For example, the

Cappadona Ranch harvests mesquite beans and is looking to mass produce mesquite

products for grocery stores & supermarkets to sell. Current mesquite bean

harvest techniques involve manual picking which requires high labor intensity

and is not very efficient. Although this process works well enough to sell

mesquite bean products locally, continuing to hand-pick mesquite bean beans

will not allow their business to grow and expand beyond what it is currently

(local small business). The Cappadonas are looking to expedite the harvesting

of mesquite beans and transition towards a more efficient technique. This will

give their business an opportunity to sell mesquite bean products at a much

larger scale. Efficiency and productivity are two things the Cappadona family

is seeking in a new and improved harvesting technique. A mechanical mesquite

bean harvester will bring exactly that.

Cappadona

Ranch Visit

o Harvesting Rate

Currently, with the family handpicking the mesquite beans from the tree for long hours, they are able to harvest approximately 5,000 pounds of mesquite beans annually (200 pounds per day); in order for them to expand their business and partner with HEB, estimates for the required harvesting rate need to be 10 times that amount (~50,000 pounds/year of mesquite).

Figure 15 - Cappadona Family on Tractor Platform

Picking Beans by Hand

o Benefits

and Nutritious Value

The

mesquite bean has a unique set of nutritious value that makes it a very healthy

addition to almost any meal. The bean is a superfood that can manage glucose

levels for those who consume it. Mesquite beans can be turned into a variety of

products such as jelly, coffee, flour, tea, bread, and soap. The flour made

from mesquite beans contains natural sugar with high fiber and protein content

that makes it diabetic friendly. In addition, the mesquite bean flour can be

used as a sugar substitute or as a seasoning. When the mesquite tree is roasted

and grounded it makes a great coffee substitute (naturally caffeine free). The

mesquite bean has a wide range of food benefits that can change the way people

eat.

Figure 16 - Collected Mesquite Beans

o Impact

on other Farmers

Texas

farmers with lots of mesquite trees on their property often contact Cappadona

Ranch about coming to pick mesquite beans off their trees. However, Cappadona

Ranch is not interested in picking beans on other properties, they are only

interested in the beans themselves; meaning the farmer needs to go out and pick

the beans off the trees themselves. Because the task of handpicking mesquite

beans is too labor intensive & time consuming for many of these farmers,

they are not able (or willing) to put in the work needed to handpick mesquite

beans. However, with a mechanical harvester, this task will become much easier

to accomplish. Farmers across south Texas will now be able to harvest mesquite

beans off their trees and sell them to Cappadona Ranch for ~$2/pound. This

would become a relatively easy job for many farmers willing to make some money from

their mesquite trees.

o

Mechanical Harvester Chain Reaction

The number one reason why Cappadona Ranch is unable to mass produce their mesquite bean products is the inefficient technique of hand-picking mesquite beans. They simply aren't able to harvest enough mesquite beans to produce enough products for mass production and distribution to grocery stores and supermarkets across the state. Hand-picking mesquite beans is restricting their business from continuing to grow and expand beyond the community level. A mechanical harvester would remove this constraint in the mesquite harvesting process and allow for a significant increase of harvested mesquite beans. This breakthrough will then allow for the mass production of mesquite bean products to markets like HEB and others. Having mesquite bean products on supermarket shelves is a big deal. Mesquite bean products are natural, healthy, and positively affect people's health. This is a superfood that has yet to reach its full potential. Having a wider range of customers learn more about the benefits of mesquite bean products will result in more and more people wanting to consume such products. From a food production perspective, mesquite bean products can have a huge impact. Increasing the amount of harvested mesquite beans will allow for new mesquite bean products to be created. The Mesquite Tree is a nutritious food source that is underutilized. A mechanical mesquite bean harvester will change how the mesquite tree is viewed and used.

To Learn More about Cappadona Ranch,

Click HERE.

Figure 17 - Cappadona Ranch Logo

DESIGN

SPECIFICATION

The Design Specification captures

the "essence" of the design. The following table shows the Design

Spec for our project.

The design specifications are subject to change as more information is discovered about the problem. The current design specifications are estimates concerning the final design of the product. If possible, these specifications will be met. Once more information through testing has been performed, the team will determine if the design specifications are feasible.

|

UTRGV |

Rev. 01 |

Design Specification (Requirement List) for the Design of a Mechanical Mesquite Bean Harvester |

Issued on: |

|

Changes |

D/W |

Specifications |

Responsible |

|

2/28/2021

2/28/2021

2/28/2021

2/28/2021 |

D

D

D

D |

Geometry - General Mechanical Harvester Dimensions Rotating Unbalance Assembly (lwh): 20 cm x 20 cm x 20 cm Compact Motor design Extender Arm Assembly (length): 4 m Long enough to reach high branches - General Collector Dimensions Canopy (Full-Spread) Radius: 2 m Large catch diameter; Wide enough to catch fallen mesquite beans from consecutive branches Canopy Carrier (lwh): 1 m x 0.75 m x 0.75 m Mobile, compact. Easy to move around |

MM

MM

MM

MM |

|

2/28/2021 2/28/2021 2/28/2021 2/28/2021

2/28/2021

2/28/2021 2/28/2021

2/28/2021 2/28/2021 2/28/2021

2/28/2021 2/28/2021 |

D D D D

D

D D

D D D

D W |

Components - Rotating Unbalance Mechanism Two (high-speed) motors (w/offset masses) (Bluetooth?) Battery Electronics Mount Platform for motor, battery, electronics Adjustable Strap Help secure to branch (up to 10 cm diameter) - Extender Arm Pole Grip Improve control; prevent slippage - Collector Canopy Carrier Off-road Wheels Mobility in rough terrain Storage Latch door Help release/transfer mesquite beans into another container |

MM MM MM MM

MM

MM MM

MM MM MM

MM MM

|

|

2/28/2021

2/28/2021

2/28/2021

2/28/2021

2/28/2021

2/28/2021

2/28/2021

2/28/2021

3/2/2021

3/2/2021

3/2/2021

|

D

W

D

D

W

W

D

W

W

D

D |

Features - Rotating Unbalance Mechanism Frequency Control Adjust frequency according to branch/beans Detachable from Extender Arm Can be attached and placed on branch manually Display Screen showing information (Battery percentage, Frequency, etc.) - Extender Arm Retractable Compact, easy storage Power Button to activate Rotating Unbalance - Collector Retractable Canopy Easy storage when not in use (can be removed/stored) Manual Deployment Using string/rope Automated (Electronic) Deployment Using electronics/motor Adjustable Tarp/Funnel Angle Wide/Narrow Collection Area Easy Access to Bean Pod Storage Once bean pod storage container is full, remove, and put in a new one. Or empty into other container & insert back. Wind-Resistant Does not sway. Remains stationary when in use. |

MM

MM

MM

MM

MM

MM

MM

MM

MM

MM |

|

2/28/2021

2/28/2021 2/28/2021

|

D

W W |

Kinematics - Rotating Unbalance Mechanism MAX Amplitude of Vibration: 10 cm - Collector 4 or 6 Bar mechanism for deployment Origami-inspired deployment

|

MM

MM MM

|

|

2/28/2021

2/28/2021

|

D

D |

Forces Generated Force Range: 10 N - 25 N Capable of generating enough force to excite beans Vibration Resistant Mechanism capable of withstanding heavy vibrations

|

MM

MM |

|

2/28/2021 2/28/2021 2/28/2021 2/28/2021

|

D D W W |

Energy Powered by Rechargeable Battery Battery Life lasts 8-10 hours. Electronics encased Does not overheat

|

MM MM MM MM |

|

2/28/2021

2/28/2021 2/28/2021 2/28/2021

2/28/2021 |

D W

D |

Materials - Rotating Unbalance Mechanism Strong, flexible materials Capable of withstanding heavy vibrations Waterproof Tough, thick tarp Does not easily rip from thorns |

BH MM BH

BH BH JS |

|

3/1/2021 3/1/2021 3/1/2021 3/1/2021 |

D D D W

|

Signals Frequency adjustment via (?) Electrical control of motor speed Feedback signal to measure Amplitude/Frequency Remote-controlled

|

PS PS MM PS

|

|

3/1/2021

3/1/2021 3/1/2021 3/1/2021

3/1/2021 3/1/2021

|

D

D D D

D D/W |

Safety Vibrations should be effective but also not damage the tree bark No physical interaction with the mesquite tree thorns Ease of installment/removal Mesh net canopy will prevent contamination that occurs when the mesquite beans contact the ground Canopy material mitigates the impact of the falling seeds Safety Factor: 3

|

PS

PS PS PS

PS MM |

|

3/1/2021

3/1/2021 3/1/2021

3/1/2021

3/1/2021 3/1/2021

3/1/2021 |

D

D D

W

D D

D |

Ergonomics - Rotating Unbalance Mechanism Lightweight (< 8 kg) - Extender Arm Lightweight (5-10 kg) Rubber grip handle (shaped) Comfortable for user Adjustable in length (up to 4 m) - Collector Adjustable clamp/grip/rope/canopy Funnel-shaped collection mechanism for fallen mesquite beans to roll in together Secure, compact, transportable, and easy-to-setup collection canopy Sort out good and bad mesquite beans when in use

|

PS

PS MM MM MM

PS PS

PS

JS

|

|

3/1/2021 3/1/2021 3/1/2021

3/1/2021 |

D D D

D |

Quality Control Experimentally tested (for performance) ASTM, ANSI Approved High quality materials For extended use Collecting as many beans as possible |

MM MM PS

JS |

|

3/1/2021 3/1/2021 3/1/2021 3/1/2021 3/1/2021 3/1/2021 3/1/2021 |

D D D D D D |

Assembly Securely assembled Vibration resistant screws Washers Motor mounts Velcro strap Adjustable sleeve/strap

|

PS PS PS PS PS PS |

|

3/1/2021 3/1/2021 3/1/2021 |

D D D

|

Operation Remote controlled or tractor attachment installed/controlled Precision in frequency settings Simple maneuverability controls |

PS PS PS

|

|

3/1/2021 3/1/2021 3/1/2021 3/1/2021 3/1/2021 3/1/2021 3/1/2021 3/1/2021 |

D D D D D D D |

Maintenance Replaceable parts Long life cycle (approx. 6-8 years) Replace motor every 4 years Ensure clean electronics compartment Check for wiring quality Recharge battery after every use Clean

canopy/canopy storage |

MM MM MM MM PS MM PS JS |

|

3/1/2021 3/1/2021 3/1/2021 |

D D D |

Costs Extremely low cost, approximately $500 High quality materials Cost

efficient (should effectively harvest mesquite beans) For Ranchers/Farmers harvesting mesquite beans |

PS PS PS JS |

The objective of the Conceptual

Design stage is to come up with ideas to solve the problem.

Here, the team is tasked with

generating effective ideas to solve the problem. This process involves defining

the overall function of the proposed solution (can be broken down into

subfunctions), finding individual solutions to each subfunction (explore "design

universe"), collecting solutions on morphological chart, creating and

evaluating combinations of solutions (concept variants), and finally, selecting

the final concept based on a thorough analysis of the generated concept variants.

FUNCTIONAL

DESIGN

Creating a Functional Diagram allows

us to understand what the product is going to do, and not

necessarily how. This allows the team to explore different

options for each subfunction within the functional diagram.

|

Figure 18 - Functional Diagram

(Excitation)

|

Click HERE to

View our Functional Diagram (Excitation & Collection).

MORPHOLOGICAL

CHART

The Morphological Chart helps us

explore the "design universe" for possible solutions to each subfunction.

This way, it helps the team focus on one subfunction at a time and find

individual solutions for each corresponding subfunction.

Below is a list of the different

subfunctions involved within the two components of the design (Excitation &

Collection). For each subfunction, the team has identified various possible

components that can perform the specified task.

EXCITATION

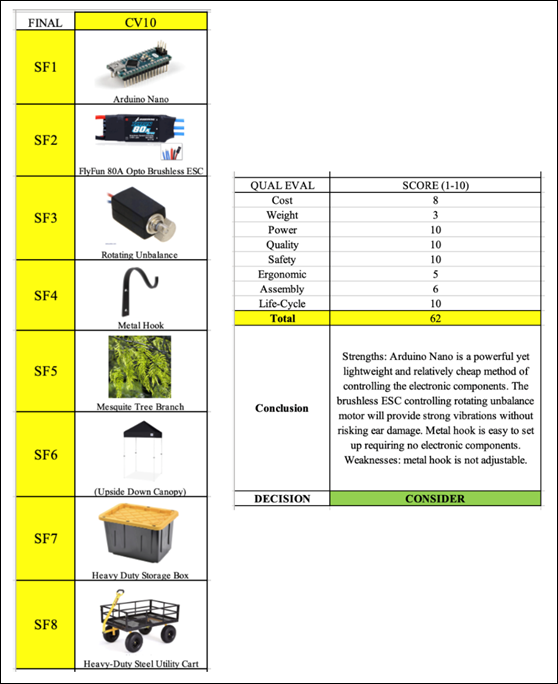

SF1 - Wireless Communication

SF2 - Electric Control Module

SF3 - Generator of Vibration

SF4 - Transmits Vibrations to Branch

SF5 - Excites Mesquite Bean Pods

Figure

20 - "Generator of Vibration" Potential Solution (Rotating Unbalance)

COLLECTION

SF6 - Funnel (Guide) Fallen Mesquite

Bean Pods

SF7 - Stores Fallen Bean Pods

SF8 - Transports Harvested Bean Pods

Figure

21 - "Stores Fallen Bean Pods" Potential Solution (Storage Bucket)

Click HERE to

View our Morphological Chart (Excitation & Collection).

CONCEPT

VARIANTS AND SELECTION PROCESS

After coming up with a variety of

solutions to address each subfunction, the team must now make combinations of

solutions for each subfunction and create concept variants. These variants will

be evaluated accordingly to identify the top solution variants.

Click HERE to View our Concept Variants.

FINAL

CONCEPT(S)

After the selection process we

arrived at the Final Concept.

Figure

22 - Final Concept Variant (CV10)

The objective of the Embodiment

Design stage is to realize the concept by performing the appropriate analysis.

This is an iterative process in

which the team continues to make the concept more real. Here, the technical

aspects of the design are addressed by applying our engineering knowledge. In

this case, such calculations and analysis will involve several engineering

subjects including Mechanical Vibrations, Dynamics, Mechanics of Solids, Machine

Elements, and Finite Element Analysis (FEA).

STRATEGIES

AND PRIORITIES

Starting from our final concept(s), the

team identified the necessary analyses and engineering work to realize the

concept into a product.

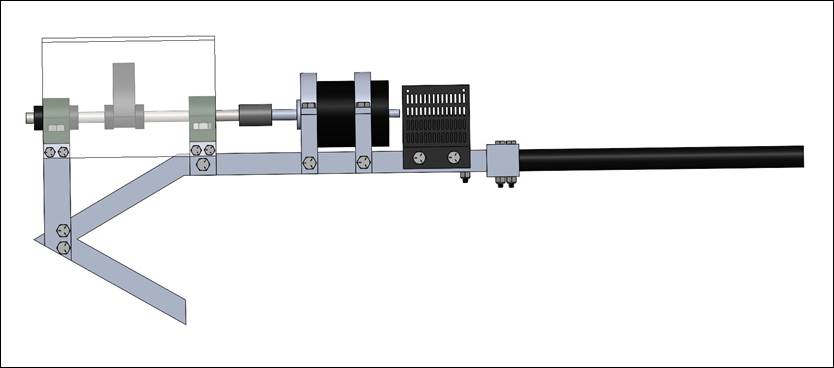

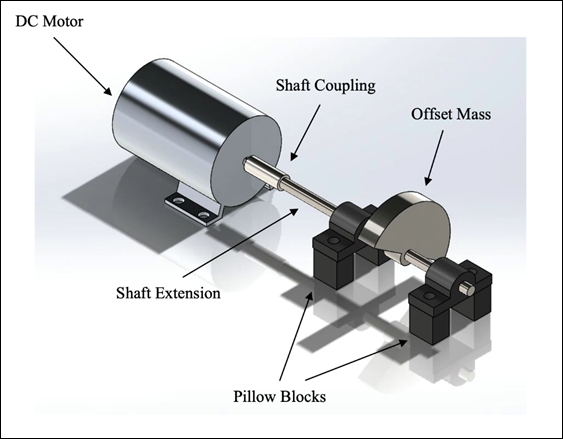

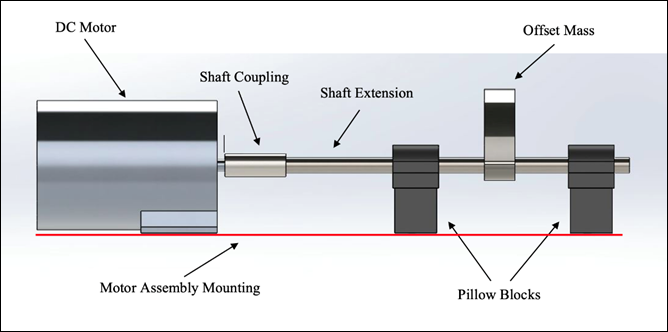

o

First

off, the team went ahead and created the components needed to construct the

motor assembly on solid works. From these parts, the team put together two different

motor assemblies.

o

Next,

different offset mass geometries were investigated to examine how different

shapes affect the magnitude of the generated force.

o

Furthermore,

the team carried out the proper analysis on these two assemblies to evaluate

and determine which assembly we should move forward with. The forces generated

by all four offset mass geometries at both natural frequencies (8 Hz & 24

Hz) were calculated first. Then, motor assembly parameters including torque

requirement (to accelerate the offset mass and the shaft), expected pillow

block forces, and bending stresses throughout the length of the shaft were

evaluated accordingly.

o

The

team then modified the SolidWorks components created according to the materials

that were purchased. In addition, different mounts were designed and

implemented into the assembly (to attach to hook). Here, the team determined it

was best to redesign the hook and allow for a more compatible branch-hook

interface. The old hook had a fixed width and could only be latched onto

branches of one specific size.

o

After

that, the team took important measurements from mesquite tree branches (at

Zinnia Park). To make the new hook more compatible, we measured the

circumference of various mesquite tree branches. From this data, a minimum,

maximum, and average diameter was computed.

o

The

team then redesigned the hook on SolidWorks based off the branch measurements

recorded. This new hook design features a tapered interface which should help

it grab on to a wide range of branch sizes.

o

A

Finite Element Analysis was performed on the Hook to investigate the effects of

the transmitted force on a hollow hook (deflection). The team wanted to know if

a hollow hook could handle the expected vibrations from the offset mass.

o

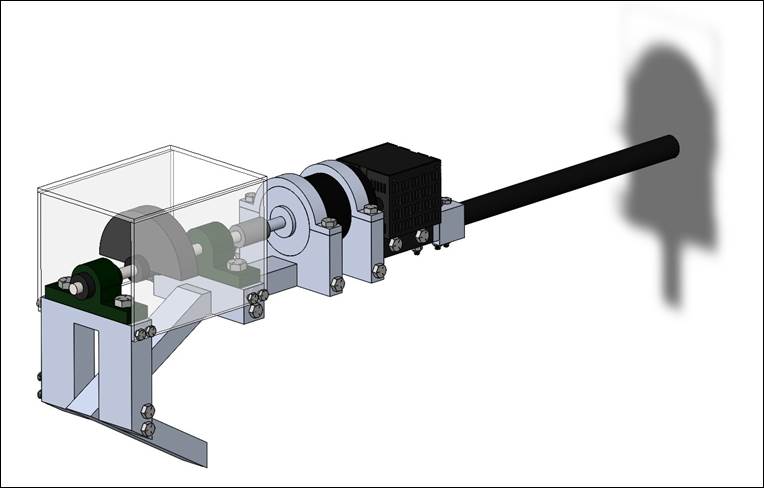

Before

proceeding to the machining phase of the project, the SolidWorks assembly model

was updated. This gave the team a better idea of where each component is placed

and how the device functions.

o

After

coming up with the drawings for each component, the team began the machining

process at the Machine Shop at UTRGV. Since this device is the first of its

kind, many of its components are custom made. This includes the mounts, hook

frame, and offset masses.

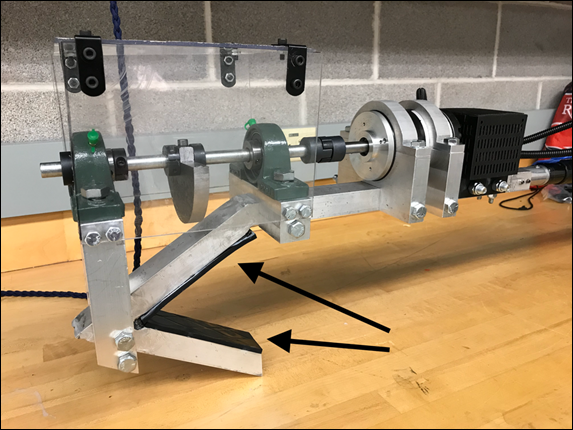

o

Once

the machining was completed, the team focused on setting up the electronics and

mounting them on the hook/pole. Both the batteries and speed controller

required 3D printed cases/housings.

o

Other

accessories were then introduced to the device including new pole grips, rubber

pads for the inside of the tapered hook section, wire tubing (protect wires),

and a clamp mount to attach the speed controller case to the pole.

TASK

1 - MOTOR ASSEMBLY MODELING

Click HERE to View Motor Assembly Components.

Figure

23 - Motor Assembly 1

Figure

24 - Motor Assembly 2

Figure

25 - Motor Assembly 1 (SIDE)

Figure

26 - Motor Assembly 2 (SIDE)

TASK

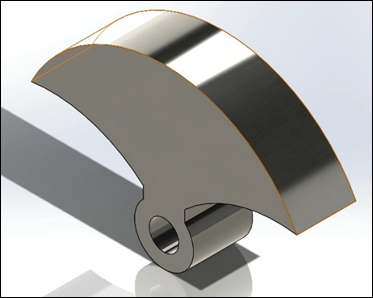

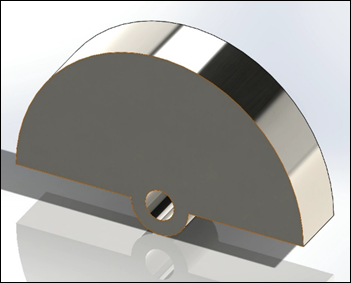

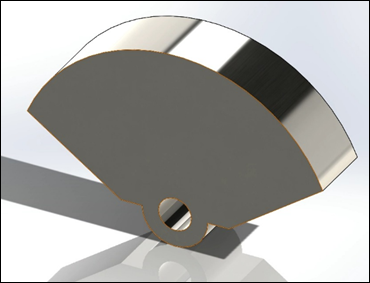

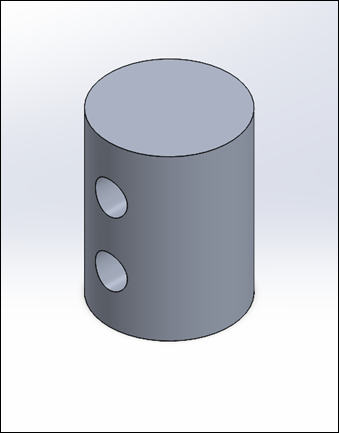

2 - OFFSET MASS GEOMETRIES

|

|

|

|

Figure 27 - Offset Mass 1 |

Figure 28 - Offset Mass 2 |

|

|

|

|

Figure 29 - Offset Mass 3 |

Figure 30 - Offset Mass 4 |

Figure

31 - Offset Mass 3 Labeled (COM, Eccentricity, Axis of Rotation)

The eccentricity is defined

as the distance from the axis of rotation to the center of mass for the

rotating unbalance.

In the figure above, both the center

of mass and the eccentricity are labeled for offset mass 3. For this geometry

and mass distribution, the eccentricity is 1.03 inches from the axis of

rotation (center of the hole that accepts the shaft).

Table 1 - Offset Mass Properties

& Parameters

|

|

Offset

Mass 1 |

Offset

Mass 2 |

Offset

Mass 3 |

Offset

Mass 4 |

|

Material

Applied |

AISI

1020 |

AISI

1020 |

AISI

1020 |

AISI

1020 |

|

Material

Density (lb/in3) |

0.29 |

0.29 |

0.29 |

0.29 |

|

Volume

(in3) |

5.83 |

5.98 |

10.01 |

8.15 |

|

Eccentricity

(in) |

1.36 |

1.39 |

1.03 |

1.18 |

|

Mass

(lb) |

1.66 |

1.71 |

2.86 |

2.32 |

NOTE: The force generated from the

rotating unbalance is linearly proportional to both the offset (unbalance) mass

and the eccentricity, while the force is proportional to the square of the

driving frequency.

TASK

3 - CALCULATIONS & ANALYSES

(a)

ROTATING UNBALANCE OVERVIEW

(Eq. 1) - Equation of Motion for

Rotating Unbalance

(Eq. 2) - Force Magnitude Generated

by Offset Mass

![]()

Click HERE to View Derivation of Equation.

Parameters:

![]() - mass of the system (kg)

- mass of the system (kg)

![]() - damping coefficient (kg/s)

- damping coefficient (kg/s)

![]() - stiffness of the system (kg/s2)

- stiffness of the system (kg/s2)

![]() - offset (unbalance) mass (kg)

- offset (unbalance) mass (kg)

![]() - eccentricity (m)

- eccentricity (m)

![]() - driving frequency (rad/s)

- driving frequency (rad/s)

t - time (sec)

![]() - translational acceleration (m/s2)

- translational acceleration (m/s2)

![]() - translational velocity (m/s)

- translational velocity (m/s)

![]() - translational displacement (m)

- translational displacement (m)

Figure

32 - Rotating Unbalance Diagram

NOTE: As seen in the equation of motion

(Eq. 1), the generated force is directly (linearly) proportional to the mass of

the rotating unbalance and the eccentricity, while being a function of the square

of the driving frequency. Although the mass and the eccentricity do affect

the magnitude of the force, the frequency at which the offset mass rotates has

a much larger influence on the force.

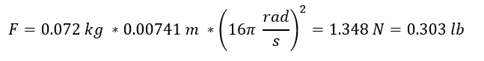

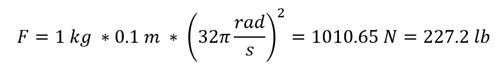

Example

1:

Force generated by small motor (with

two small offset masses) at a driving frequency of 8 Hz.

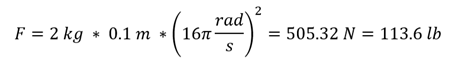

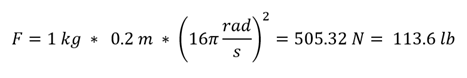

Case of 1 kg mass and 0.1m

eccentricity at a driving frequency of 8 Hz.

Example

2:

Note that in the case of doubling

either the mass or eccentricity, the force generated is also doubled. Comparing

the following two equations to the case of 1 kg and 0.1 m, the generated force

is doubled.

However, because the driving

frequency is squared, doubling the driving frequency quadruples the generated

force.

(b)

FORCE GENERATED BY VIBRATION (OFFSET MASS)

Table 2 - Natural Frequencies of

Mesquite Beans (BENDING)

|

|

First (Lower) |

Second (Upper) |

|

|

8.0486 |

24.045 |

|

|

50.571 |

151.079 |

NOTE: Natural Frequencies of Mesquite

Beans gathered by previous team.

Click HERE to View Conversion of Natural

Frequencies.

![]()

![]()

![]()

NOTE: ![]()

Offset Mass Material: AISI 1020

(Steel)

AISI 1020 (Steel) Density, ![]()

Offset Mass 3

![]() ,

, ![]() ,

, ![]()

![]()

![]()

![]()

NOTE: ![]()

|

|

Generated Force by Offset Mass 3 at ![]()

![]()

![]()

|

|

Generated Force by Offset Mass 3 at ![]()

For Rest of Offset Mass Force

Calculations, Click HERE.

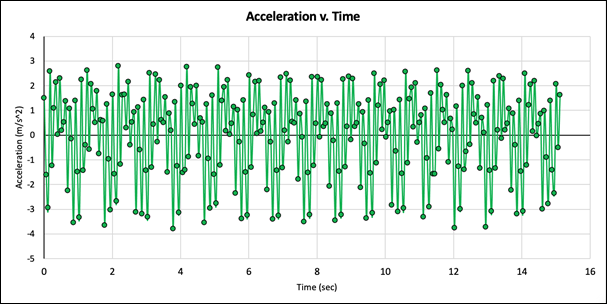

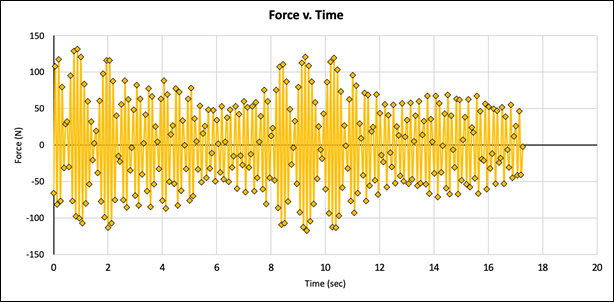

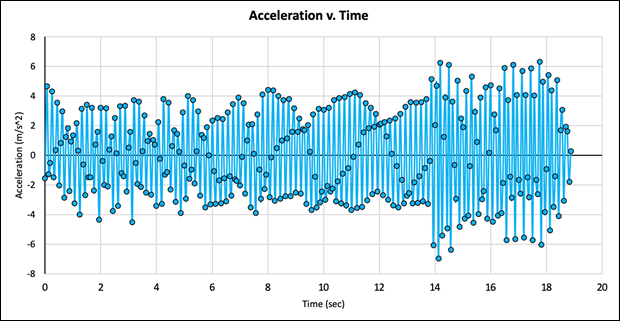

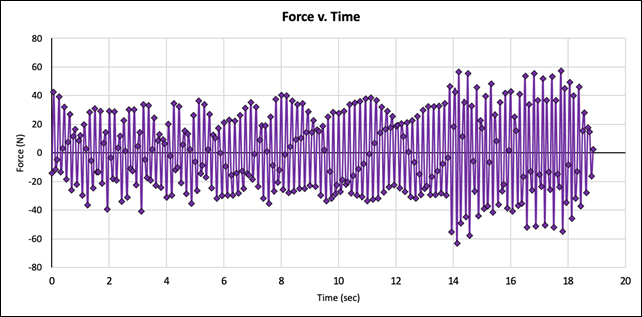

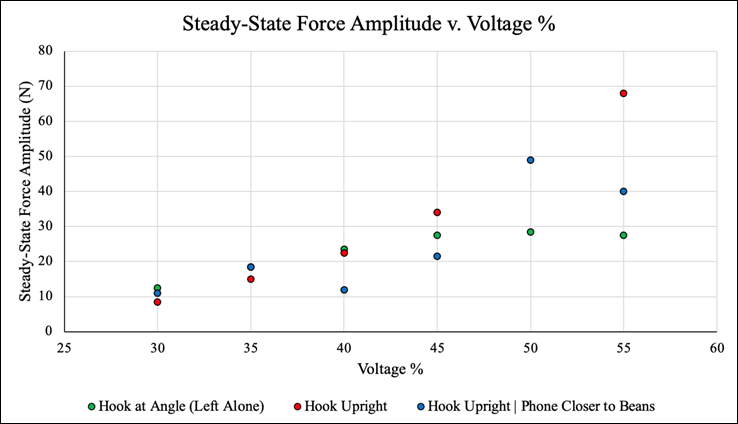

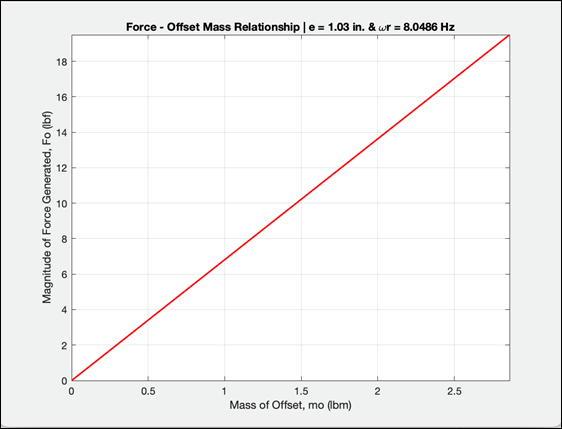

Graphs are shown below depicting the

relationship between the magnitude of the force generated, ![]() , and the different parameters that make

it up (mass of offset,

, and the different parameters that make

it up (mass of offset, ![]() , eccentricity,

, eccentricity, ![]() , and driving frequency,

, and driving frequency, ![]() ). Although the generated force is directly

proportional to both the offset mass and the eccentricity, it is a function of the

square of the driving frequency.

). Although the generated force is directly

proportional to both the offset mass and the eccentricity, it is a function of the

square of the driving frequency.

Figure

33 - Force - Offset Mass Relationship

Here, the relationship between the

generated force and the offset mass is shown with constant eccentricity of 1.03

inches (Offset Mass 3) and constant driving frequency of 8.0486 Hz (first

natural frequency). The relationship is linear (constant rate of change). The

magnitude of the force generated increases as the mass of the offset increases.

In this case, the largest force generated (19.497 lbs) occurs at a mass of 2.86

pounds (mass of Offset Mass 3).

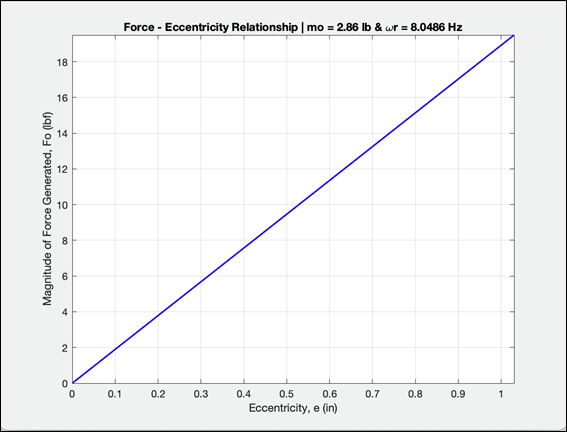

Figure

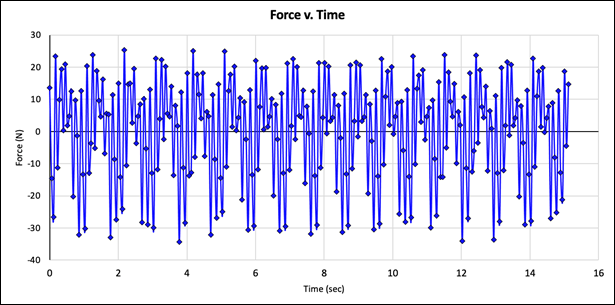

34 - Force - Eccentricity Relationship

Pictured above is the relationship

between the magnitude of the force generated and the eccentricity of the offset

mass with fixed parameters. The mass of the offset is 2.86 pounds (Offset Mass)

and the driving frequency is 8.0486 Hz (first natural frequency). Similar to the

previous graph, the generated force is directly related to the eccentricity of

the offset mass. As the eccentricity increases, so does the magnitude of the

force generated (linearly). With the mass of the offset and the driving

frequency held constant, the largest generated force is 19.497 pounds at an

eccentricity of 1.03 inches.

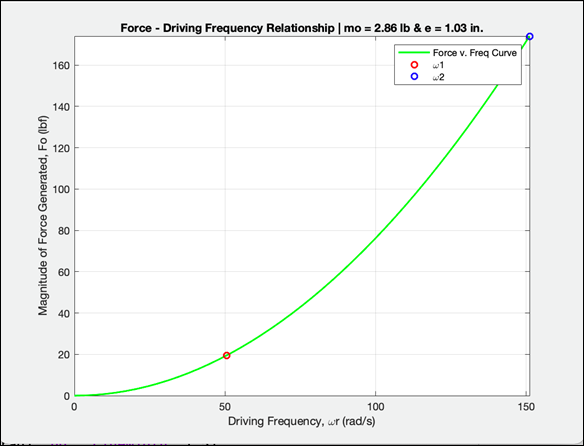

Figure

35 - Force - Driving Frequency Relationship

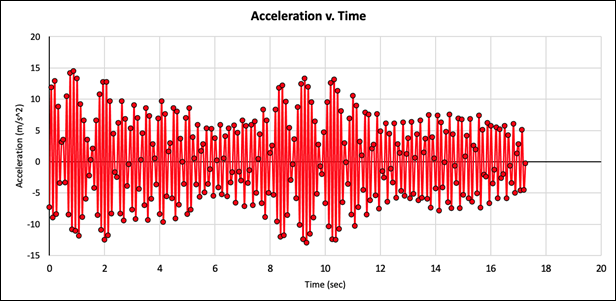

Unlike the previous two graphs, the relationship

between the generated force and the driving frequency is not linear, but

instead quadratic. In this case, the rate of change increases as the driving

frequency is increased. This way, one can generate a larger force much quicker

by simply increasing the frequency at which the offset mass is spun. This

scenario is more controllable since the physical parameters of the offset mass

(mass & eccentricity) don't have to be adjusted to increase or decrease the

magnitude of the force. Therefore, the team intends on using the driving

frequency as the main parameter to adjust the generated force.

Click HERE To View MATLAB Codes.

(c)

TORQUE REQUIREMENT

Offset Mass 3

Given (SolidWorks): ![]()

Required to reach a speed of ![]() = 8 Hz in

= 8 Hz in ![]() = 3 seconds.

= 3 seconds.

![]()

Angular Acceleration, ![]()

![]()

![]()

Torque, ![]()

![]()

|

|

Required Torque to rotate Offset

Mass 3 at ![]()

To View Torque Requirement Hand Calculations,

Click HERE.

(d)

PILLOW BLOCK FORCES (ASSEM. 1 & 2)

The team is very interested in the

expected (reaction) forces within the two pillow blocks (for both assemblies).

In order to move forward with one motor assembly, the team must compare the

forces within each set of pillow blocks. These calculations will also go a long

way in determining what type of pillow blocks we will end up purchasing. Such

pillow blocks will need to withstand the loads calculated.

By considering the DC Motor as a

fixed support, the shaft extension as a beam, the pillow blocks as journal

bearings, and the offset mass as a point load, one is able to diagram the motor

assembly as a Statics/Mechanics of Solids problem. However, after determining

the number of reactions within the setup, the team realizes there are more

unknown reactions (5) than there are equilibrium equations (3). Therefore, the

structure is considered statically indeterminate.

NOTE: Assume all reactions as positive

Still, there is a way to solve the

problem. By applying the method of superposition, one is able to isolate the

point load (force generated by offset mass) from the each of the two vertical

reaction forces at the pillow blocks. In this case, the two reaction forces at

the pillow blocks are converted into point loads at their respective locations.

Then, it is determined that summation of the deflections at the two pillow block

locations (A & B) due to the three individual loads is equal to zero. With

this, one is able to establish two equations in which the two pillow block

forces (Ay & By) are unknown.

The various deflections can be

calculated by considering the shaft extension as a cantilever beam with

concentrated loads at the end or concentrated loads at any point (using machine

elements booklet). Once both equations have all the appropriate deflections,

one can solve for the two pillow block reactions. Then, using the equations of

equilibrium, the reactions at the fixed support (motor) can be solved for. MATLAB

was used to verify the hand calculations.

The reaction forces at the pillow

blocks for Motor Assembly 1 are both greater than those of Motor Assembly 2. Ay

for Assembly 1 is approximately 1.7x greater than Ay for Assembly 2. On the

other hand, By for Assembly 1 is close to 6x larger than By for Assembly 2.

This is a glaring difference in the pillow reaction forces between the two

motor assemblies. In this case, assembly 1 causes a very large amount of load

to be directed at the pillow block between the offset mass and the other pillow

block.

From these calculations, assembly 1

does not seem ideal to implement. One of the pillow blocks will be carrying a

significantly larger load than the other. In addition, assembly 1 causes the

forces within the pillow blocks to be larger than the load itself (offset mass

force). Although assembly 2 still imparts relatively large reaction forces on

the two pillow blocks, they are a lot less than those within assembly 1.

Click HERE to View Pillow Block Forces

Calculations (Assem. 1 & 2).

Click HERE to View MATLAB Codes.

(e)

BENDING STRESSES IN SHAFT (ASSEM. 1 & 2)

Once the reaction forces at each of

the pillow blocks have been solved for, one is then able to calculate the

(maximum) bending stresses within the shafts of both assemblies. First, the

shear and bending moment diagrams are drawn. Then, since the diameter of the

extension shaft does not change, one is able to calculate the maximum bending

stress by identifying the largest magnitude bending moment on the diagram and

plugging it in into the appropriate bending stress equation.

For a solid round bar- ![]()

![]() - Bending Moment

- Bending Moment

![]() - Diameter of shaft

- Diameter of shaft

|

Assem. 1: |

|

Assem. 2: |

After carrying out the appropriate

calculations, it is determined that the maximum bending stress within the shaft

in assembly 1 is approximately 2.6x greater than the maximum bending stress

with the shaft in assembly 2. Again, since the diameter of the shafts do not

change, one can determine which stress will be larger and by how much just by

looking at the maximum bending moment within the assembly.

After calculating both, the expected forces at the pillow

blocks and the maximum bending stresses within the shafts of each assembly, it

is clear that assembly 2 is the best option. Assembly 2 does not demand an

extremely large reaction force out of one of the pillow blocks and has a

significantly smaller maximum bending stress within its shaft.

Still, further analysis will be conducted to verify these

results and continue gathering more information regarding other aspects of the

motor assembly designs.

Click HERE to View Bending Stress Calculations.

TASK

4 - SOLIDWORKS UPDATE

Figure

36 - Hook Assembly Model (Version 1)

After

discussions with our Faculty Advisor (Dr. Fuentes), we realized that the hook had

a fixed width and was not compatible with branches of various sizes. This geometry

is not ideal since the hook is only able to attach to branches of one specific

size. The team decided it was best to redesign the hook based on measurements

(circumference/diameter) from actual mesquite tree branches.

TASK

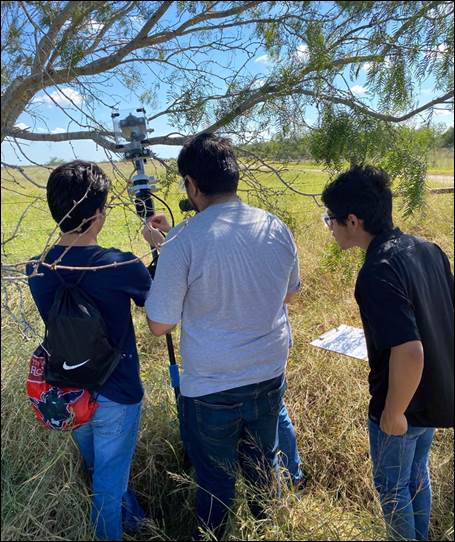

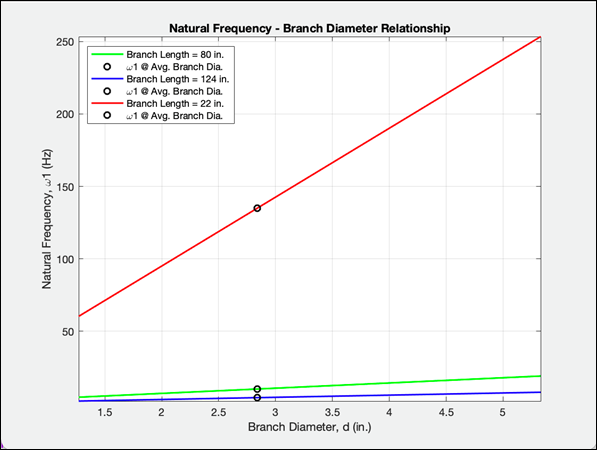

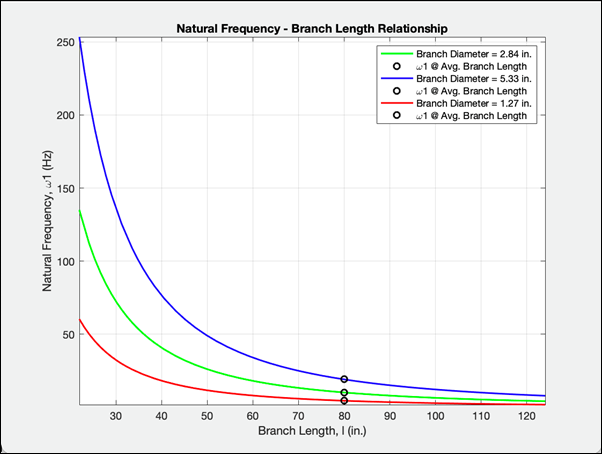

5 - BRANCH MEASUREMENTS

With the goal of redesigning the

hook, the team went out to Zinnia Park in McAllen and took measurements of

Mesquite Trees, measuring the circumference of different mesquite tree branches

throughout the park. This was done to determine the range of diameters the hook

will need to be compatible with. Below is a table that summarizes the data we

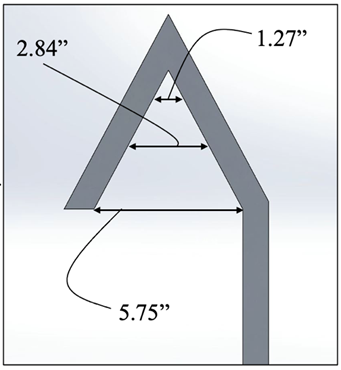

collected. We measured an average branch diameter of 2.84 inches.

Table 3 - Mesquite Tree Branch

Diameter Data

|

Minimum |

1.27" |

|

Maximum |

5.33" |

|

Average |

2.84" |

|

Figure 37 - Measuring

Circumference of Branch |

Figure 38 - Mesquite Tree Branches |

|

Figure 39 - Mesquite Tree Branch |

Figure 40 - Measuring Circumference of Branch |

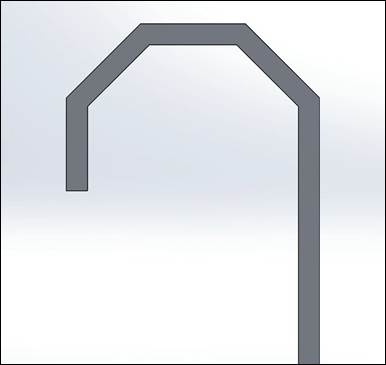

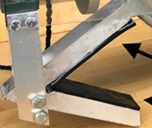

TASK

6 - HOOK REDESIGN

To redesign the hook, the team

developed a new tapered interface which is more adept to firmly grabbing the

range of most branch diameters that will be encountered when harvesting

mesquite beans. It's a relatively simple design that requires no adjusting. We

believe this design will prove to be effective and provide ease of use. The new

geometry the team came up with is angled like a V-shape. The idea behind this

design is that the hook would have a firm grasp on the mesquite tree branches

at various distances from the vertex of the inner triangle.

|

Figure 41 - Old Hook (Previous

Team) |

Figure 42 - NEW Hook (Redesign) |

Figure 43 - Hook - Branch Compatibility

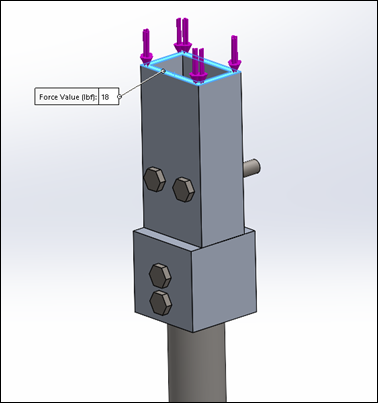

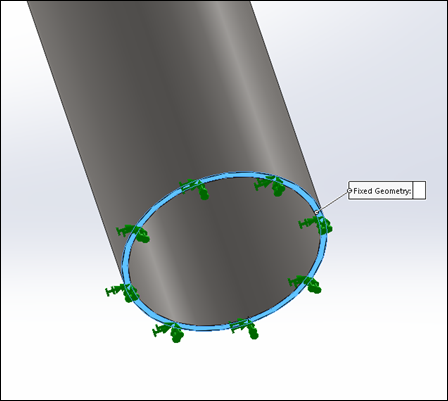

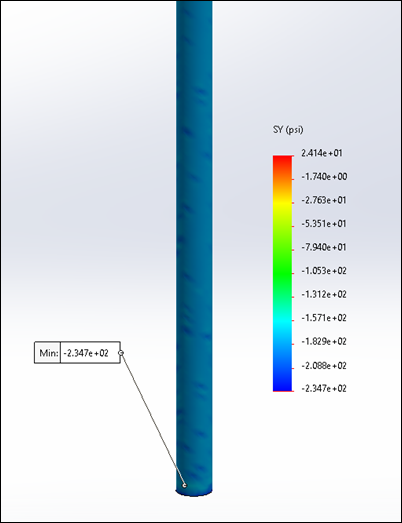

(a)

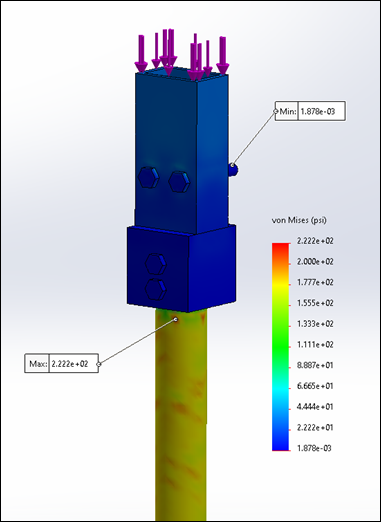

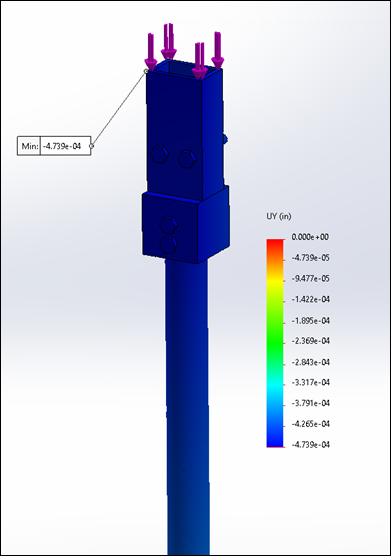

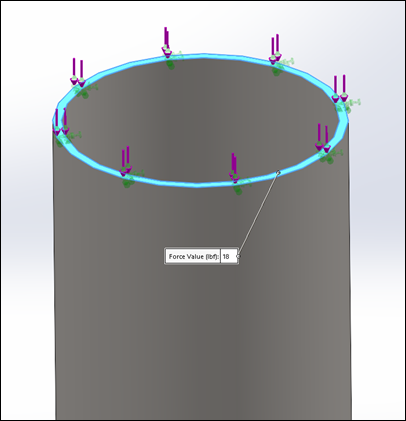

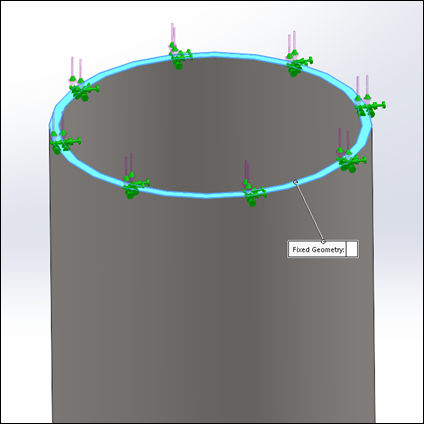

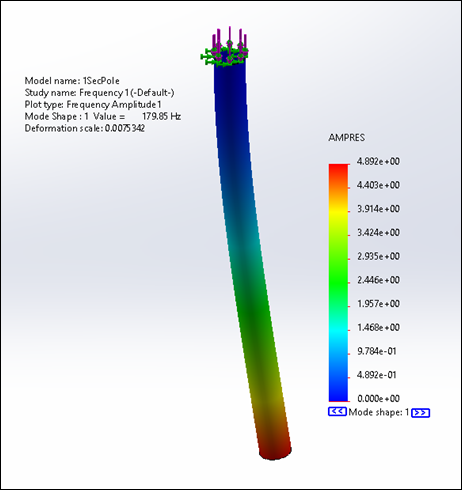

FINITE ELEMENT ANALYSIS

The team originally planned on using

a solid aluminum hook. After presenting this idea to our faculty advisor, we

were asked to consider a hollow hook instead. The concern with using a hollow

hook rather than solid was that it would not be able to withstand the expected

vibrations. To test this, the team used SolidWorks to model the hollow aluminum

hook, then ran a Finite Element Analysis on the hollow model. The results

showed that the hollow aluminum hook would be able to withstand the expected

vibrations (negligible deflection). This is advantageous over the solid

aluminum hook since it dramatically reduces weight. This led the team to move

forward with a hollow hook.

Figure

44 - FEA Simulation of Hollow Hook

TASK

7 - UPDATED SOLIDWORKS ASSEMBLY

Figure

45 - Hook Assembly Model (Version 2)

TASK

8 - MACHINING & ASSEMBLY

Once all the raw materials arrived,

the team began work in the machine shop manufacturing the following components.

o

Lower

Motor Mounts

o

Upper

Motor Mounts

o

Lower

Pillow Block Mount

o

Upper

Pillow Block Mount

o

Hook

Frame

o

Hook

Insert

o

Offset

Mass

o Shaft

o

Polycarbonate

Case

Aluminum 6061-T6 was the metal alloy

chosen to make the hook frame and its components (mounts) out of. 6061 Aluminum

is, by any measure, the most commonly used aluminum alloy in the world. It is

useful in almost any application due to its strength, heat treatability,

machinability, weldability, as well as high resistance to corrosion, stress,

& cracking. In our case, we needed an alloy that had a good strength-to-weight

ratio and was relatively easy to machine and weld.

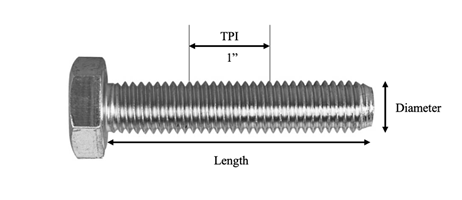

Bolt Sizes

Bolt Size: 3/8" - 16 x 2"

(Diameter) " - (TPI) x (Length)

"

When dealing with bolts, it is

important to know how bolt sizes are defined (U.S. Customary). Bolts are

defined by their diameter, threads per inch (TPI), and length. The first number

indicates the diameter of the bolt (in inches) while the second number indicates

the number of threads per inch measured along the length of the bolt. The third

number defines the length of the bolt. For the example above, the bolt is 3/8

inches in diameter, has 16 threads per inch, and a length of 2 inches.

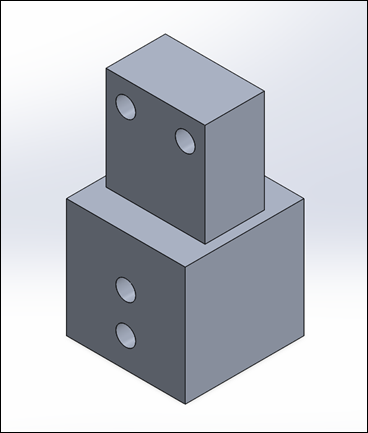

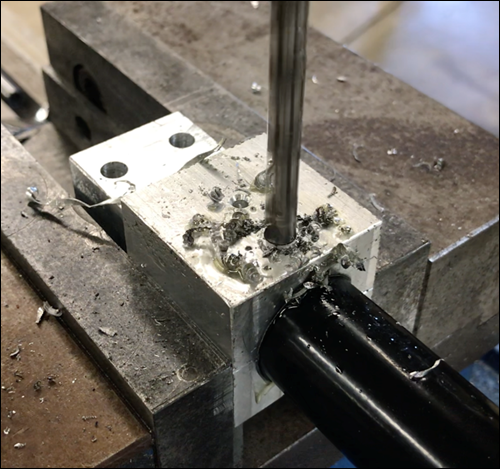

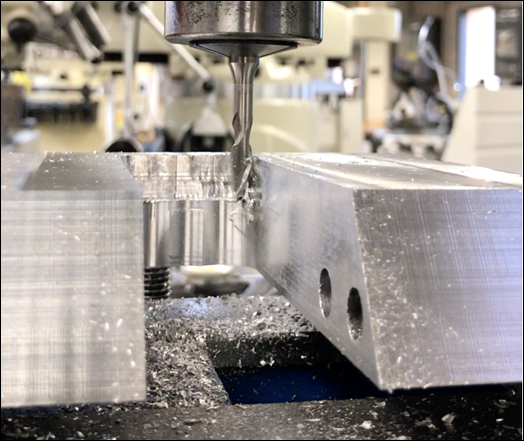

Lower

Motor Mounts

The lower motor mounts provide a

resting platform for the motor to be attached to the hook. First, 3"

diameter holes were cut using a circular cutter on the mill machine (allows

motor to fit on top). Then, a 3/8" hole was drilled through the length of

each mount. This through-all hole will allow a bolt and nut to secure the

mounts onto the hook frame. Next, 1" x 1.5" rectangular cuts were created

using endmills. These rectangular slots allow the mounts to be inserted onto

the base of the hook frame. Finally, 5/16" holes were drilled & tapped

(3/8"-16) onto both sides of each mount to allow the upper mounts to be

secured on top. Countersinks were done on each hole to deburr the rough edges.

|

Figure 46 - Cutting 3" Hole |

Figure 47 - Drilling 3/8" Hole |

Figure

48 - Lower Motor Mounts

NOTE:

To View SolidWorks Part Drawing (Lower Motor Mount), Click HERE

Upper

Motor Mounts

The purpose of the upper motor

mounts is to secure the DC Motor into place by attaching to the lower motor

mounts with bolts. The 3" circular hole was again done by using the

circular cutter on the mill. Then, 3/8" holes were drilled through the

center of each rectangular tab (with countersink). 3/8"-16 bolts will go

through these holes and connect to the lower motor mount. This will keep the

motor secured in place. After that, an endmill was used to create rectangular

tabs on each end of the mounts. Next, we adjusted the mill to a 45-degree angle

to create angled cuts. This was done to approximate the outer circular shape.

To get closer to the desired circular shape, we used the vertical belt sander. This

allowed us to carefully shape the outer curvature.

|

Figure 49 - Cutting Excess |

Figure 50 - Angled Cuts using Mill

(45 deg) |

Figure

51 - Using Belt Sander to Shape Outer Curvature

Figure

52 - Upper Motor Mounts

NOTE:

To View SolidWorks Part Drawing (Upper Motor Mount), Click HERE

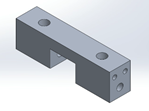

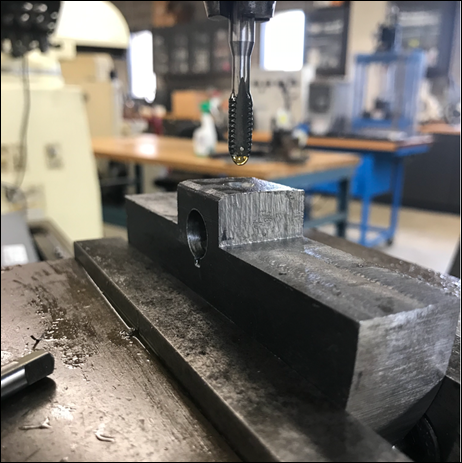

Lower

Pillow Block Mount

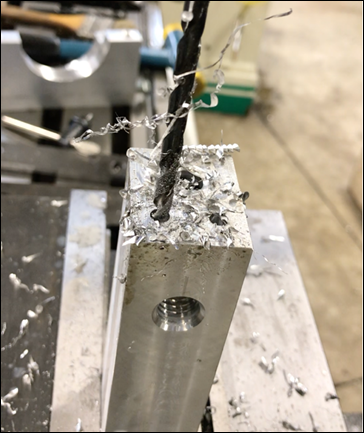

The lower pillow block mount allows

the pillow block closest to the motor to be secured onto the hook frame.

Similar to the lower motor mounts, a 3/8" hole was drilled through the

long side of the mount. A 6.5" long 3/8" bolt will pass through this

hole and connect the mount to the hook frame (using Nylon Insert Lock Nut). Next,

27/64" holes were drilled and tapped (1/2"-13) on top of the mount.

These threaded holes allow the pillow block to be bolted onto the mount. Two

0.2010" (#7 drill size) holes were then drilled and tapped (1/4"-20)

onto both sides of the lower pillow block mount. The polycarbonate case that

surrounds the offset mass will be bolted onto these threaded holes (on lower

and upper pillow block mounts). Finally, a rectangular slot (1" x 1.5")

was cut out using an endmill. Again, this slot allows the mount to be inserted

onto the hook frame.

Figure

53 - Using Tap to Create Threads in Hole

|

Figure 54 - Drilling 0.2010"

Holes |

Figure 55 - Cutting Rectangular

Slot |

Figure

56 - Lower Pillow Block Mount

NOTE:

To View SolidWorks Part Drawing (Lower Pillow Block Mount), Click HERE

Upper

Pillow Block Mount

The upper pillow block mount attaches

near the vertex of the hook frame and provides a platform for the pillow block furthest

away from the motor to be secured onto. Considering this a relatively large

component, two 3/8" holes were drilled through the mount for attachment to

the hook (bolts and nuts). Again, two 27/64" holes were drilled and tapped

(1/2"-13) on top of the mount, used to bolt down the pillow block. Two

0.2010" (#7 drill size) holes were also drilled and tapped (1/4"-20)

onto both sides of the mount (used to secure polycarbonate case). This

particular mount features an incline that allows it to be flushed with the

tapered section of the hook frame. Similar to the upper motor mounts, the mill

was adjusted to 30-degrees

from the vertical to cut this incline gradually (using an endmill). Finally, a

large rectangular slot was cut out through the middle section to allow the hook

frame to fit in between.

|

Figure 57 - Cutting Incline |

Figure 58 - Preparing to Cut Slot |

Figure

59 - Trimming Slot Edges

NOTE:

To View SolidWorks Part Drawing (Upper Pillow Block Mount), Click HERE

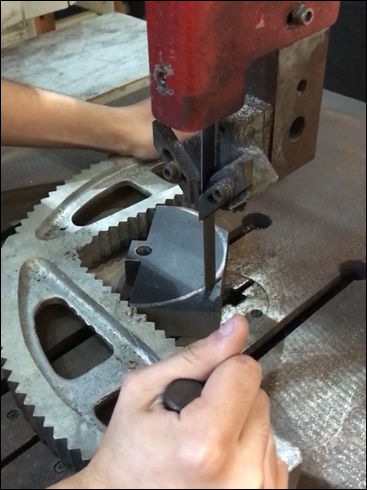

Hook

Frame

To create the hook, three hook frame

pieces were cut from one 3-foot-long rectangular aluminum tube (1" x 1.5")

using the horizontal bandsaw. These pieces were then trimmed to the appropriate

angle at each end (to connect with one another) using the vertical bandsaw.

After a careful sanding of the rough edges, the three pieces were tig welded

together. Since the hook is hollow, it was relatively easy to join the pieces

together. The Air angle die grinder was used to smooth out the welded joints. 3/8"

holes were then drilled through the hook at specific locations to allow the

mounts to be secured.

|

Figure 60 - Cutting Hook Piece 1 |

Figure 61 - Cutting Hook Piece 3

Excess |

Figure

62 - Hook Frame

Figure

63 - Drilling 3/8" Holes onto Hook Frame

NOTE:

To View SolidWorks Part Drawing (Hook Pieces 1-3), Click HERE

Hook

Insert

To connect the hook frame to the

pole, a hook insert was created. This hook insert began as a 1" x 1.5"

x 3" solid aluminum block. First, a 3/4" hole was drilled onto its

bottom side. This allows the pole tip to be attached. To fix this connection,

two roll pins were pressed through the hook insert and pole tip. Next, the other

side of the hook insert was machined to fit the inside of the hollow hook base.

Once the hook insert fit tightly into the hook frame, two 1/4" holes were

drilled through the hook frame and hook insert. These holes allow the hook

frame to be bolted onto the hook insert (detachable if desired).

Figure 64 - Drilling Hole for Roll Pin

|

Figure 65 - Drilling 3/4"

Hole |

Figure 66 - Pressing Roll Pins |

Figure

67 - Hook Frame attached to Pole

NOTE:

To View SolidWorks Part Drawing (Hook Insert), Click HERE

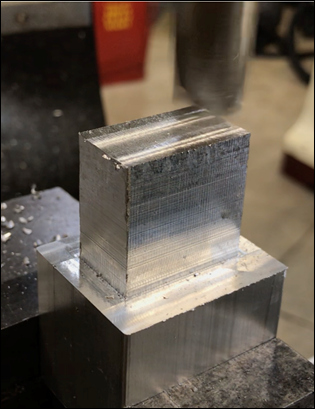

Offset

Mass

The

offset mass will be used to generate a force when spun by the motor (about the

shaft). In this case, A36 Carbon Steel was chosen due to its relatively high

density. This mild carbon steel grade contains chemical alloys that give it

properties such as ductility and strength, while being perfectly suitable for

grinding, drilling, tapping, and machining processes. To start off, a 4-flute

endmill was used to cut off excess on each side of the steel block to create a

rectangular tab in the center. This tab will be used to drill the hole on which

the shaft will be inserted through. Next, a 1/2" hole was drilled into the

center of this rectangular tab (shaft insert). Initially we tried to use the

circular cutter to cut out the circular shape. However, since steel is much

stronger than aluminum, this method was ineffective in cutting through.

Instead, we used the vertical bandsaw to trim the outer curvature as close as

possible, after which we used the belt sander to smooth out the edges.

|

Figure 68 - Cutting Excess (4-Flute) |

Figure 69 - Cutting Excess

(Roughing Endmill) |

Figure

70 - Ben (Left) & Paul (Right) Milling Offset Mass

Figure

71 - Milling Offset Mass with Roughing Endmill (Adding Coolant)

Figure

72 - Ben (Left) & Miguel (Right) Milling Offset Mass

|

Figure 73 - Drilling 1/2"

Hole |

Figure 74 - Trimming Outer

Curvature |

|

|

|

|

Figures 75 & 76 - Using Belt

Sander to Round Offset Mass Edges |

|

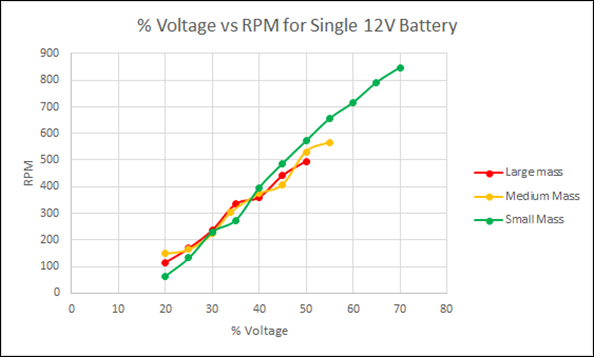

To investigate the effects of

lighter offset masses on the generated force, thinner offset masses were

machined (same shape). With the original offset mass being 1 inch thick, the

other two masses machined are 0.75 inches thick and 0.5 inches thick. These

masses are interchangeable within the device. Since the generated force is

directly proportional to the square of the driving frequency, we want to find

out if a lighter mass spun at a higher frequency can generate a similar force

to that of a larger mass spun at a lower frequency.

NOTE:

To View SolidWorks Part Drawing (Offset Masses), Click HERE

Shaft

The shaft that will drive the offset

mass was cut to the appropriate length using the horizontal bandsaw. The shaft

is made of Steel and is 0.5" in diameter. In this case, the shaft will

connect to the motor via a spider coupling and guided through pillow blocks.

The offset mass will then be mounted through the shaft, between the two pillow

blocks. Two shaft collars will hold the offset mass in place. To transmit the

torque from the motor to the offset mass, a 0.2010" hole was drilled and

tapped (1/4"-20) through the bottom end of the offset mass, through the

shaft, and onto the other side of the offset mass. This allows a set bolt to

connect the offset mass to the shaft and transmit the torque. This method was

carried out on each one of the offset masses. Although the team originally wanted

to implement a key and slot joint to transmit the torque, the machine shop did

not have a broach size that would work with the offset mass.

Figure

77 - Tapping Offset Mass

Polycarbonate

Case

A polycarbonate case was put

together to prevent any type of personal injury from the offset mass and/or interference

from protruding twigs and branches. This case is made from three clear, impact-resistant

polycarbonate panels, joined together with L-brackets. The polycarbonate panels

were cut to scale using the vertical bandsaw. The case was then placed around

the offset mass, being bolted into the sides of the lower and upper pillow

block mounts. Again, this case ensures no one is harmed during operation

(spinning offset mass) as well as protects the offset mass from hitting any

twigs or small branches when up on a tree.

Figure

78 - Cutting Polycarbonate Panel using Vertical Bandsaw

NOTE:

To View SolidWorks Part Drawing (Polycarbonate Panels), Click HERE

Assembly

Once all the components had been

machined, the team was able to assemble the device. Although some parts were a

tighter fit than others, we were able to piece together each component. In this

case, we used nylon insert lock nuts to secure each mount onto the hook. Since

the assembly will undergo heavy vibrations during operation, we want to make

sure nothing comes loose. Nylon nuts are a type of locking nut that resist

loosening caused by vibration and normal use. Unlike free spinning nuts, nylon lock

nuts make use of a deforming elastic to stay in position against torque and

shock.

During assembly, it is important to

make sure the pillow blocks are aligned correctly. This allows the shaft to be

inserted smoothly and straight. In any case, the spider coupling (connects

motor output shaft to extended shaft) is designed to accept shaft misalignment and

help protect components from damage by damping shock and vibrations. Also, shaft

collars are positioned on each side of the pillow block furthest away from the

motor to prevent the shaft from translating in or out. Finally, each set

screw/bolt on the assembly (coupling, shaft collars, pillow blocks) must be

screwed onto the shaft. This helps prevent the coupling from detaching as well

as the offset mass from coming loose and sliding to one side.

Overall, the assembly process is

relatively simple and easy to follow. Each component is removable and can be

taken off if needed. Tools required for assembly include an adjustable wrench

(and/or ratchet), vice grips, and allen keys (different sizes).

Figure

79 - Assembled Hook without Case (Front View)

Figure

80 - Assembled Hook without Case

Figure

81 - Assembled Hook with Case (Front View)

CHECK OUT our Machining Process. See Video

Below!

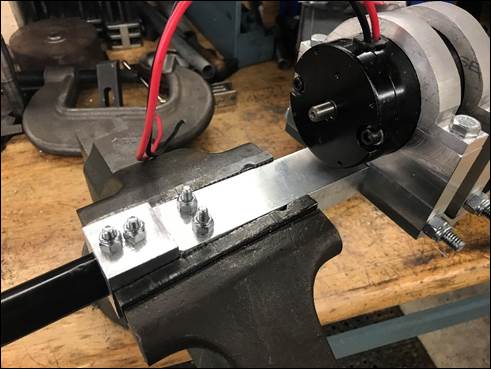

TASK

9 - ELECTRONICS & 3D PRINTING

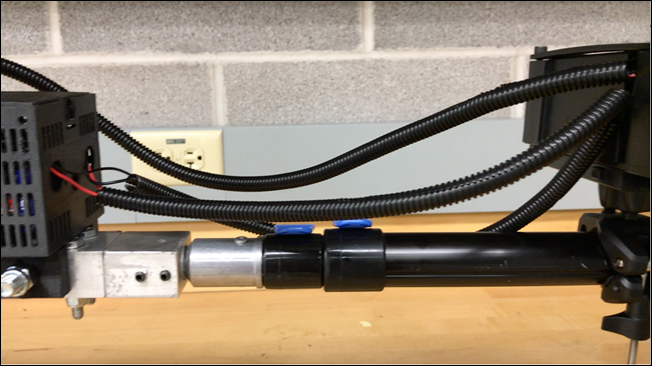

After assembling all the mechanical

components of the hook device, the team shifted its focus towards the

electronics. The motor will receive its power from two 12V batteries. These

batteries will need to be mounted on the hook and near the motor. To solve

this, the team designed a battery case that will house both batteries and be

mounted directly behind the motor. In addition, to control the speed of the

motor, a speed controller will be used. The speed controller connects to both

the batteries and the motor and controls the voltage sent to the motor via a

potentiometer (knob). The speed controller must be easy to use and not have

wires exposed. The team therefore decided to design a case for the speed

controller that will house the speed controller along with the ON/OFF button

and potentiometer. A cover lid was also designed to secure the speed controller

in place. The lid has openings that allow access to the ON/OFF button and the

potentiometer, as well as an opening to see the display (% Power). The speed

controller will be mounted on the pole to allow the user access to the

controls.

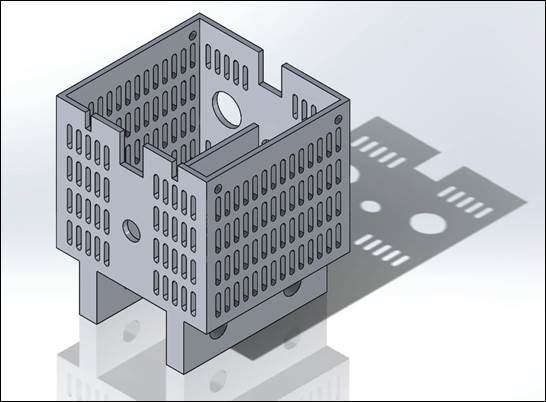

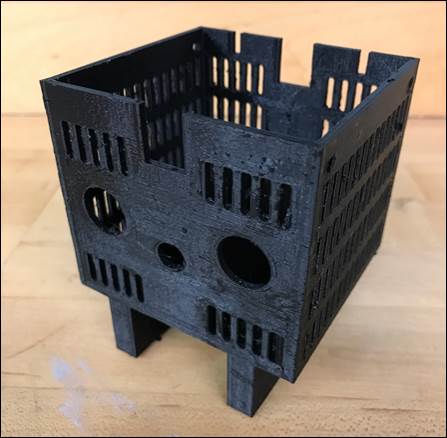

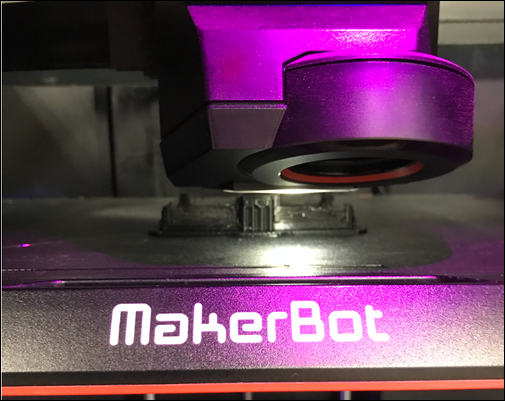

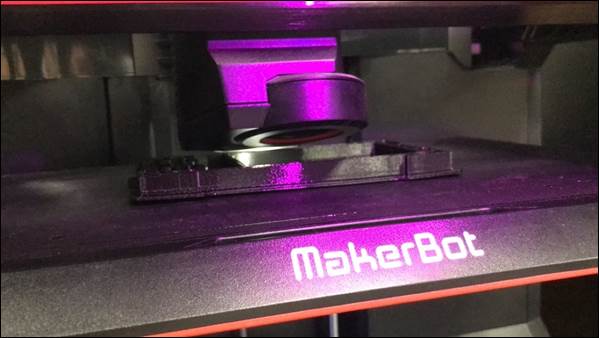

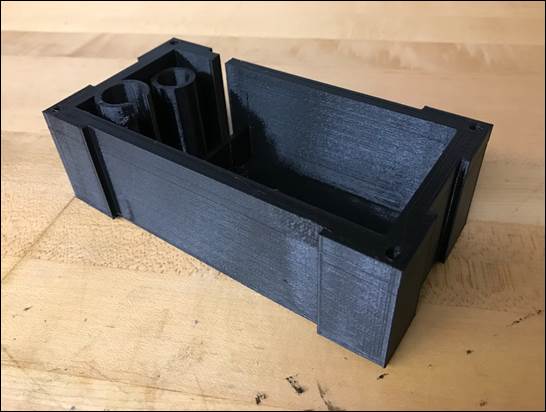

Battery Case

The battery case has two slots for

the pair of batteries to be inserted. The four walls surrounding the batteries

have multiple openings to allow for heat to be dissipated during use. The case

has two circular openings on the back side of the case to allow the battery

wires to go through and connect to the speed controller. The case also has two

side panels on its bottom side that allow it to sit on top of the hook frame. Each

of these panels has two 3/8" holes that serve to secure the case to the

hook frame (using bolts and nuts). A removable lid was also designed to close the

case and prevent the batteries from slipping out during operation. Both the

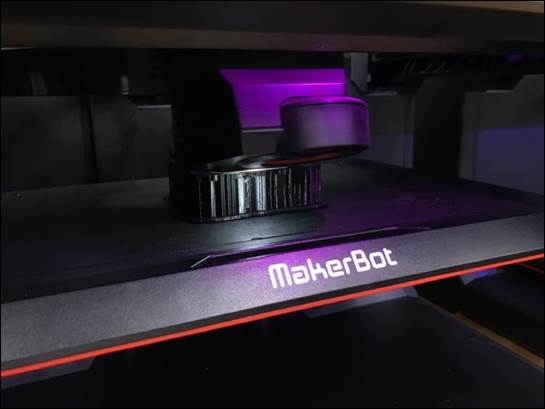

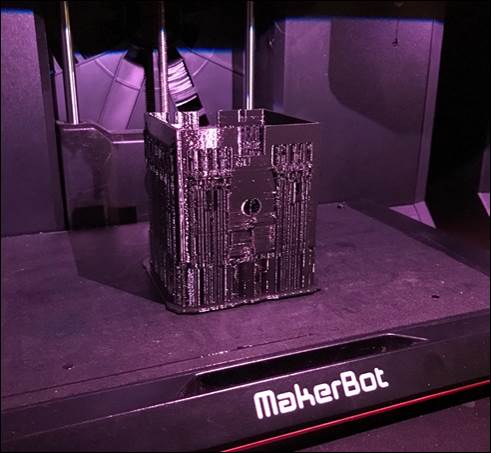

battery case and lid were designed on SolidWorks and 3D printed using the

MakerBot Replicator +.

Figure

82 - Battery Case on SolidWorks

Figure

83 - 3D printing Battery Case

Figure

84 - Battery Case with Supports (Excess)

Figure

85 - Battery Case (Excess Removed)

Figure

86 - 3D printing Battery Case Lid

Figure

87 - Battery Case on Hook

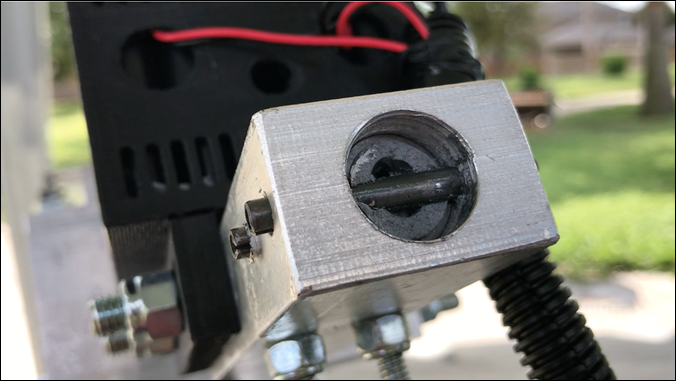

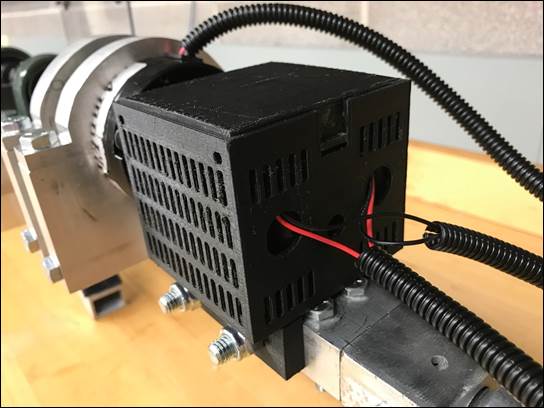

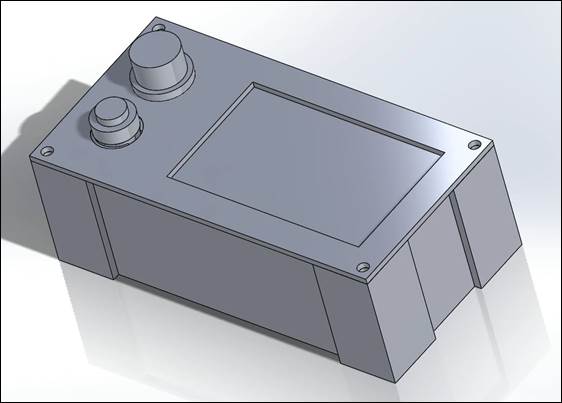

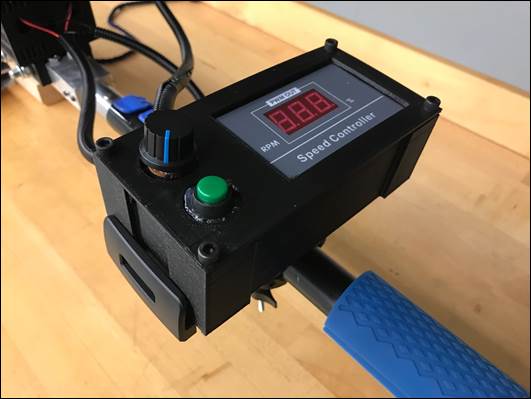

Speed

Controller Case

The speed controller case is a

rectangular box that has supports for the speed controller to sit on top of as

well as two hollow cylinders extruded from the base that house the ON/OFF

button and potentiometer. On the back side there is a rectangular slot that

allows the wires from the motor/batteries to enter the case and connect to the

speed controller. On each corner, there are holes for the lid to be screwed on.

Again, the cover lid has two holes that allow access to the button and

potentiometer as well as a rectangular opening for the speed controller

display. The speed controller case will be mounted to the pole using an

adjustable clamp mount. Both the speed controller case and cover lid were

designed on SolidWorks and 3D printed using the MakerBot Replicator +.

Figure

88 - Speed Controller Case & Lid on SolidWorks

Figure

89 - 3D Printing Speed Controller Case

Figure

90 - Speed Controller Case

Figure

91 - Speed Controller Case Lid

Figure

92 - Speed Controller Inside Case

Figure

93 - Speed Controller Case Mounted

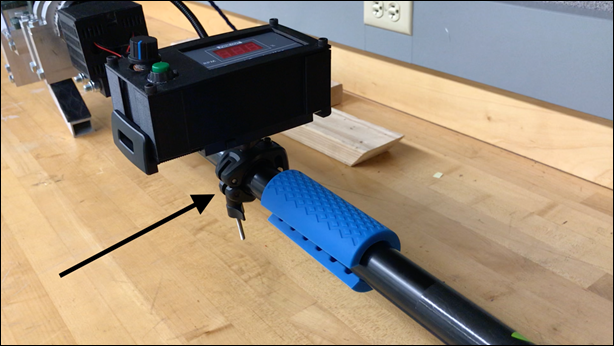

TASK

10 - OTHER ATTACHMENTS

To attach the speed controller case

to the pole, an adjustable clamp mount (meant for tablets) was purchased. This

mount will hold the case in place while being clamped to the pole. This way,

the user can always control the device. Rubber pads were also glued (super

glue) to the tapered section of the hook to improve the grip on the branch. A

grill pattern design (tread) was pressed onto the rubber pads using the

hydraulic press. This will enhance the grip of the rubber pads. In addition,

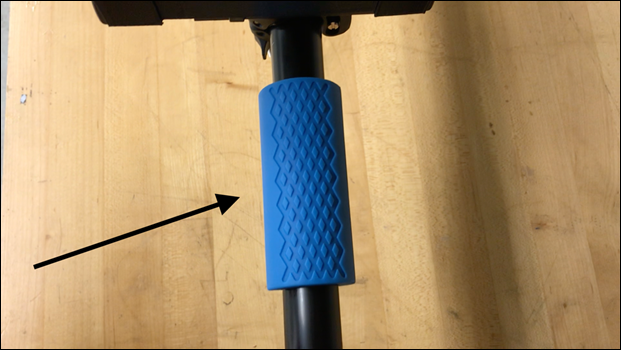

rubber pole grips were added to the pole. Although the pole came with pole

grips, they were made from foam and did not provide sufficient grip when

handling. These new grips give the user a much firmer grip when maneuvering the

device. Also, wire tubing was added to the battery and motor wires. This was

done to provide abrasion resistance and environmental protection. Together,

these attachments provide a better user-experience while improving the

performance of the device.

Figure

94 - Adjustable Clamp Mount (Speed Controller)

Figure

95 - Rubber Pad Attachments

Figure

96 - Rubber Pole Grips

Figure 97 - Wire Tubing

CHECK OUT our 3D Printing Process. See

Video Below!

Design for X (DFX)

DFX stands for Design For [Variable]

"X", where X's are not mutually exclusive since there are always tradeoffs.

X can include things such as- Function, Usability, Safety, Manufacture, Assembly,

Reliability, Maintainability, Environment, Appearance, & Variety.

Design For Assembly (DFA):

Design of the components that consider how the assembly will be performed to

ensure that the costs are optimized (minimized).

1st -

Electronic components were minimized by using a simple analog circuit and motor

with no Arduino or computer to control the speed. Only necessary parts were

included in the mechanical components.

2nd -

No parts were joined in the final assembly unless it was necessary for the

parts to be connected during use. Only simple joints (bolts, screws) were used

in the assembly.

3rd -

The device can be disassembled and taken apart, replacing the individual

components with another similar component. This was achieved by using easy to

manufacture parts with standard components like nuts, bolts, screws, and

electronics. This makes it easy and convenient to replace any broken or damaged

parts with another similar component.

4th -

The assembly or the device is a simple process that requires several common

tools.

5th -

In the assembly process, the main hook is used as a reference for locating the

positions of the remaining components.

6th -

The speed controller case was designed in SolidWorks using "top-down"

assembly. This made it convenient to ensure that the body and the lid were

compatible by referring to each other in the assembly file.

7th -

Due to the nature of the device, being required to reach tall branches, the

center of gravity is somewhat high. However, several options for lowering

center of gravity are being discussed to make the part easier to maneuver.

8th

- Currently, most of the weight is concentrated near the top of the device.

This poses some stability issues due to the center of gravity being offset.

9th

- The design of the hook is a bit heavy but is durable to carry by one person.

The weight of the hook is about 20 lbs. or so.

10th

- The polycarbonate wall is to prevent any safety hazards like someone sticking

their fingers inside while the offset mass is at operations, when in operation

no branches or twigs can tied around the offset mass while in use.

11th

- No shimming is necessary in the assembly of the device. Appropriate

tolerances of +/- 0.005" allow the parts to fit snugly in their specified

position. It also eliminates the presence of any gaps, making any shimming

unnecessary.

12th

- Most of the device's joints are left exposed for easy access to the

fasteners. In the case that components are covered by the polycarbonate case,

the casing is clear, which still allows the user to easily see inside. The

polycarbonate casing can be easily removed to allow access to the inner

components if any adjustment is needed.

13th

- All mechanical fasteners (nuts/bolts) are standardized products that can be

easily purchased in bulk from suppliers.

14th

- The entire hook assembly is symmetric (left/right). All the manufactured

components (mounts, offset masses) are symmetrical about one axis (at least).

15th

- The proper location of all components is easy to determine. Components will

not be able to be fastened in the wrong position.

16th

- The device is designed so that it can be easily adjustable. However, if the

device is adjusted to the user's liking, it will not need to be regularly re-adjusted

to maintain its position. Nylon nuts are used to ensure that the fasteners do

not easily loosen during normal vibration of the device.

17th

- Wire tubing is added to the wires connecting the speed controller to the batteries

and motor. This not only keeps them from tangling but also prevents the wires

from getting damaged due to the outdoor elements.

18th

- The hollow aluminum tubing and solid aluminum bars used in the manufacture of

the components are sufficiently sturdy, providing a robust device that can

withstand its expected loads.

19th -

The upper pillow block mount has a chamfer that aligns with the angle of the

hook. The rectangular shapes cut away from the lower pillow block mount and

lower motor mounts ensure that they will be symmetrical with the hook.

20th

- In creating the engineering drawings, proper notation was used and thorough

information easily communicated the design intentions to the manufacturer. A

user manual detailing assembly of the device is in progress.

21st

- When designing the mechanical components to the hook, threading, drilling,

etc. were used during the time in the machine. After completing each component,

most of them had burr inside the trilling. Therefore, they had to be removed

for the components to fit inside properly.

Design For Manufacture (DFM): The design is considered with

regards to the process of manufacturing it and lowering the costs needed for

it.

1st -

Using a taper hook instead of an adjustable one along with having pure analog

components for the electronics simplifies the design of the hook assembly. The

blocky metal pieces are secured using simple nuts and bolts.

2nd -

When designing the device, the equipment available to us and their capabilities

were considered. Only parts that could be manufactured in the machine shop were

designed. This equipment includes milling machine, lathe, tig welder, and belt

sander.

3rd

- Aluminum was selected for its light weight and decent strength; good strength-to-weight

ratio and is affordable.

4th

- The main hook assembly frame maintains a constant cross-sectional area; stress concentrations are not a

considerable risk as the aluminum frame has uniform wall thickness.

5th

- First use the horizontal bandsaw to cut an estimate for the outer edge

dimensions of the rectangular pieces (both for the metal and polycarbonate

materials). Mill all the metal blocks to its border size (rectangular prisms),

then mill out all the corners and right angles of the block pieces. Drill all

the holes of all the pieces with the smallest diameter specified in the

blueprints, then all the holes with the next biggest diameter, and so on [until

all holes of all sizes are drilled]. Apply the same practice with the holes

that require threading (use tap drills and taps). Finally, angle the Mill

machine to manufacture the slanted geometries of the appropriate metal pieces.

Other pieces with curved geometries were first subject to the vertical bandsaw

and then the belt sander.

6th

- For the mill, we tried to stay on the same constant number (zeroing out each

time) when we drilled holes to each block piece.

7th

- A tolerance of +/- 0.005 inches was chosen to maintain adequate design while

not spending too much time on minute details.

8th

- To minimize weight of the device, hollow aluminum tubing was chosen, rather

than solid pieces. To ensure a wall thickness of 0.125" was sufficient to

withstand its expected loads, finite element analysis was performed.

9th

- Standardized nuts and bolts were utilized in the assembly of the device. This