UTRGV / COLLEGE

OF ENGINEERING AND COMPUTER SCIENCE / MECHANICAL ENGINEERING DEPARTMENT

TEAM 9 - Design of a Mechanical Mesquite Bean Harvester

|

SDII Students (L-R) |

o

Paul Silva o

Miguel Martinez o

Benjamin Huerta o Joshua Sanchez |

|

Faculty Advisors |

o Dr. Arturo Fuentes o Dr. Joanne Rampersad-Ammons |

|

Course Instructors |

o

Dr. Noe

Vargas Hernandez o

Mr. Greg

Potter |

|

College of Business and Entrepreneurship Collaboration |

o Dr. Sylvia Robles (Instructor) o Daniel Castillo o Felipe Montemayor |

WHAT IS THE PROBLEM WE ARE TRYING TO SOLVE?

WHY IS THIS PROBLEM IMPORTANT?

LEARN MORE ABOUT OUR DESIGN PROCESS

Welcome!

We are Team 9, "Ripple Effect". Our project is titled, "Design

of a Mechanical Mesquite Bean Harvester". The mesquite bean harvester is a

mechanical device designed to provide an efficient harvesting technique that

will expedite the mesquite bean harvesting process. The mechanical harvester will

significantly reduce the time and manual labor necessary to harvest mesquite

bean pods every harvest season.

|

Figure

1 - Collected Mesquite Beans |

Mesquite

is one of the most widely distributed trees in the state of Texas. Of all the

Mesquite in the United States, 76 percent grows in Texas. The most prevalent of

this subset is the honey mesquite (Prosopis glandulosa).

The mesquite tree produces beans which mature in late summer and develop in a

long, yellowish-brown pod between four and ten inches long. They are harvested

and turned into a variety of delicious and highly nutritious mesquite bean

products such as jellies, flour, tea, and coffee.

|

Figure

2 - Honey Mesquite Tree on Texas Field |

Figure

3 - Mesquite Seedpods Hanging from Branch |

|

Figure

4 - Cappadona Ranch Mesquite Bean Jelly |

|

Current mesquite bean harvesting

methods are performed primarily by hand. This technique is labor-intensive,

dangerous (large, sharp thorns on mesquite trees may cause injury), and inefficient.

Hand-picking mesquite beans requires a lot of effort and time from the part of

the farmers. Manually harvesting mesquite beans is not necessarily something

that can help a farmer increase its mesquite bean yield and thus their supply

of mesquite bean products.

|

Figure 5 - Cappadona

Family Hand-picking Mesquite Beans |

Therefore, our task is to develop a

device capable of harvesting mesquite beans in a much more efficient manner. This

will not only save time for mesquite farmers, but also provide a safer

alternative to hand-picking. The rest of this webpage contains more information

about our project and the approach we took. We hope that you will find this

project interesting and fun.

Watch our Welcome Video Below!

In collaboration with the Business

Team - Mesquite Bean Harvest.

CLICK HERE to View Business Model & Value

Proposition.

Farmers across the RGV who harvest

(or are looking to harvest) mesquite beans for mass production of a product

need an effective, mechanized solution for harvesting mesquite bean pods.

Traditional mesquite bean harvesting

methods are performed primarily by hand. This process is not ideal for mass

harvesting since it takes lots of time picking bean pods one-by-one. In

addition, mesquite trees have huge, vicious thorns which may cause injury

during manual harvesting. The amount of physical effort required to perform

this harvesting process is challenging and not very efficient. With a limited

mesquite bean harvesting process, a business is not able to grow and expand its

supply of mesquite bean products to others in a mass quantity.

|

Figure 6 - Farmers Hand-Picking

Beans |

Figure 7 - Harvested Mesquite Bean

Pods |

To better understand the problem, we

conducted background research on the following relevant topics.

From this we learned the following:

Mesquite Trees & Beans

o Mesquite

trees are a tough, resilient plant species that thrive across the American

Southwest. Of all the Mesquite in the United States, 76 percent grows in Texas.

The most prevalent species in Texas is the honey mesquite (Prosopis glandulosa).

o Honey

Mesquite trees vary considerably in size, depending on growing conditions &

their environment. In cases where water is plentiful, and the seedlings are not

damaged by weather or wild animals, trees can grow up to 50 feet tall, with a

branch spread of 40 feet or more.

|

Figure

8 - Mesquite Tree with Complex Geometry |

o Mesquite

trees tend to grow into very complex geometries. Usually, the trunk "forks"

a few feet above the ground, causing the tree to grow out in all directions. In

some cases, if a new shoot is disturbed, the tree develops into a sprawling

multi-trunked shrub.

o Mesquite

trees are armed with sharp, stout thorns up to two inches long that emerge from

the base of the leaf stems.

|

Figure

9 - Mesquite Tree Thorns |

o Mesquite

trees possess several characteristics that help it thrive in the toughest environments.

The arid conditions of the southwest have been ideal for the mesquite, since it

requires little water, and has developed several adaptations that help it

survive prolonged droughts.

o One

of these adaptations is the tree's root system. Mesquite maintains two set of

roots - extremely long taproots to reach deep water sources, and broad, shallow

roots to capture water from brief rain events. Their taproots will find

subsurface water at depths of 200 feet below the surface, while the surface

roots extend 50 feet or more past outer edge of the crown (branch width). The

reach of their roots has given mesquite trees a considerable advantage in

desert-like environments. Their wide-spreading, deep-rooted systems enable the

tree to improve its germination and growth in xeric conditions.

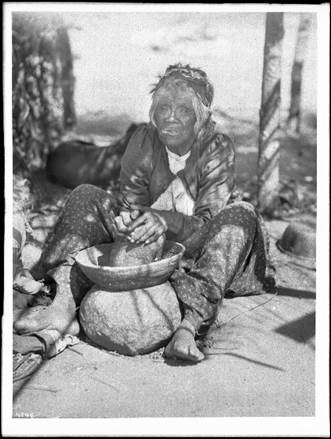

o Mesquite

trees have long been used by Native Americans across the Southwest for a bevy

of things including food, beverages, medicine, glue, firewood, construction

material, and more. The native people grounded mesquite beans and pods into

meal and high protein flour. In addition, Native Americans also collected and

boiled mesquite flowers to make tea. Mesquite gum, herbage, roots, and bark

were all used in medicinal applications. Mesquite wood serves as an excellent

fuel source and was sought after by many Native American groups. The Native

people were able to take full advantage of the many useful resources the

mesquite tree has to offer. It therefore earned the title, "Tree of Life".

|

Figure

10 - Native American Woman Grounding Mesquite Beans |

Figure

11 - Metate and Mano (Stone Bowl and Tool used to grind mesquite beans) |

Cappadona Ranch Visit

o

Problems with Current Technique (Hand-Picking)

Very

tiring (especially due to the hot, humid weather). Must always watch out for

sharp thorns. Inefficient due to accessibility of mesquite beans. Mesquite

trees grow in a variety of shapes and forms. Some are somewhat straight and

grow upward, while others grow into a thicket of swirly branches which are

almost impenetrable. This causes some difficulty in trying to pick the mesquite

beans off the trees. Some are almost impossible to get to

due to the way the tree is formed. Right now, a tractor with an elevation

platform is used to reach the beans that are way up high. Overall, very tedious

process that requires a lot of effort.

|

Figure

12 - Cappadona Family on Tractor Platform Picking

Beans by Hand |

To learn more about Cappadona Ranch, Click HERE.

Vibrating Mechanisms

(Rotating Unbalance)

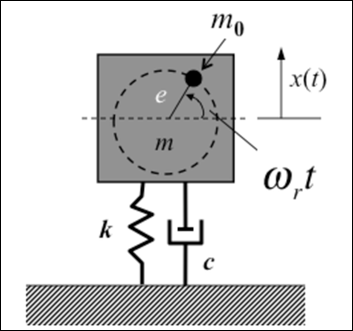

o There

are many different mechanisms that are used to induce vibration. One of the

most common methods involves a rotating unbalance. Rotating unbalance is

defined as the uneven distribution of mass around an axis of rotation.

o Unbalance

is caused when the center of mass (inertia axis) is out of alignment with the

center of rotation (geometric axis). When an object is forced to spin about a

fixed axis and the mass is not evenly distributed about that fixed axis, then a

centrifugal force develops and induces an excitation force that causes

vibration within a structure.

|

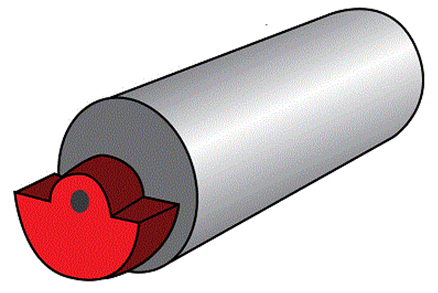

Figure

13 - Eccentric Rotating Mass |

Figure 14 - Rotating Unbalance (Motor) |

o Small

irregularities in the distribution of a mass in the rotating component of a

machine can produce substantial vibration. A rotating unbalance can be

represented as a mass, ![]() ,

rotating with an angular velocity,

,

rotating with an angular velocity, ![]() ,

at a distance,

,

at a distance, ![]() ,

from the center of rotation.

,

from the center of rotation.

Competitive

Products

Currently, mechanical harvesters

exist for various types of fruits and nuts (apples, walnuts, pecans, olives,

etc.). Although there are no

devices specifically designed to harvest mesquite beans, there are devices

which are used to harvest other products (fruits/nuts) in a similar manner.

Within the current market, there are a couple of harvester devices that can

potentially be used to harvest mesquite beans in addition to their intended

use. Below is an image of a Kadioglu EMR400 Branch

Shaker Harvesting Machine, which is used to harvest walnuts from trees. Although

this device is not meant to harvest mesquite beans, it is something that can be

analyzed as such.

|

|

|

|

Figure 15 - Kadioglu

EMR400 Branch Shaker Harvesting Machine |

|

Click HERE to view product website.

Our main motivation to work on the

mesquite bean harvester is to expedite the mesquite bean harvesting process by

designing a device capable of harvesting mesquite beans at a more efficient clip.

This will lead to a significant increase in harvested mesquite beans and enable

farmers to mass produce their mesquite bean products. With farmers mass

producing their mesquite bean products to supermarkets (HEB, Walmart, Sprouts,

etc.) across the region, their local business can grow & expand its revenue

beyond what it currently is.

This device can also be found attractive to those who have several mesquite trees within their property and are looking to make some money. Mesquite farmers often receive many calls regarding people offering their mesquite trees with ready-to-harvest beans. The problem is, farmers aren't necessarily looking to go pick beans on other people's property, they want the person themselves to harvest the mesquite beans and sell the harvested beans to them (per pound). This device can help some of those people who want to harvest mesquite beans in an efficient manner and sell them to farmers within the region.

In addition, mesquite beans are

considered a superfood; meaning it provides excellent health benefits from an

exceptional nutrient density. Mesquite bean products contain lots of nutrients

and can help people eat a much healthier diet.

|

Figure 16 - Cappadona

Family Picking Mesquite Beans one-by-one. |

Figure 17 - Mesquite Bean Flour is

diabetic friendly (contains natural sugar with high fiber and protein

content) |

|

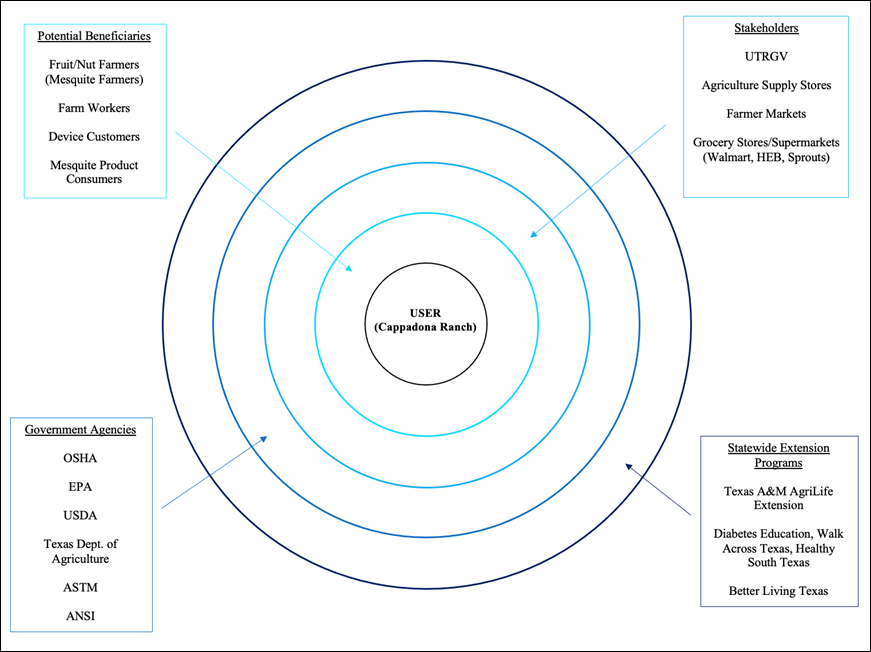

Figure 18 - Stakeholder Map |

The figure above illustrates the

people, companies, and organizations that will be affected in one way or

another by the product we develop. During the development of this product, we

must consider all those who have some connection to this device.

"We

propose the design of a mechanical mesquite bean harvester to expedite the

labor-intensive, time-consuming process of hand-picking. "

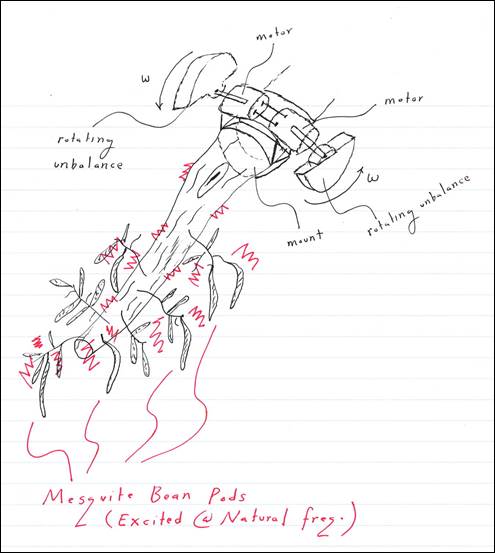

After understanding the problem in

depth, we explored various potential solutions. We utilized an evaluation

procedure to help us select the most effective concept. Our proposed solution

will utilize a rotating unbalance to generate vibrations, which will excite the

mesquite beans attached to a branch, causing them to fall. Furthermore, the

fallen mesquite beans will be collected by a catching mechanism located beneath

the branch. Together, these two mechanisms will enable farmers to efficiently

harvest mesquite beans.

|

Figure 19 - Rotating Unbalance

Sketch |

|

Figure 20 - Rotating Unbalance (DC

Motor) |

Once we defined a clear solution

idea (concept), the team applied its engineering knowledge to transform it into

a real product.

|

|

|

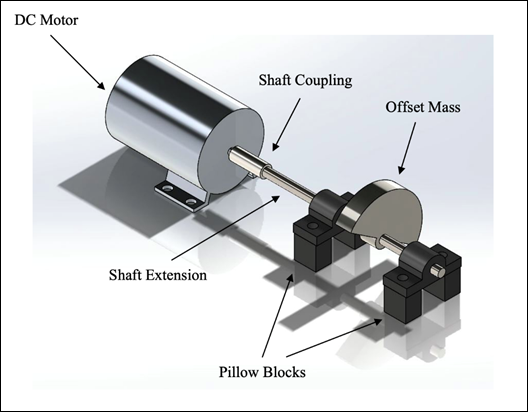

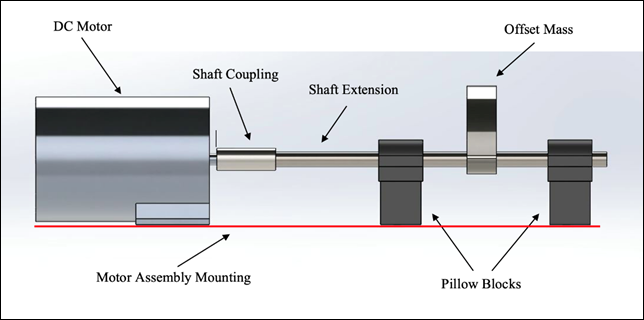

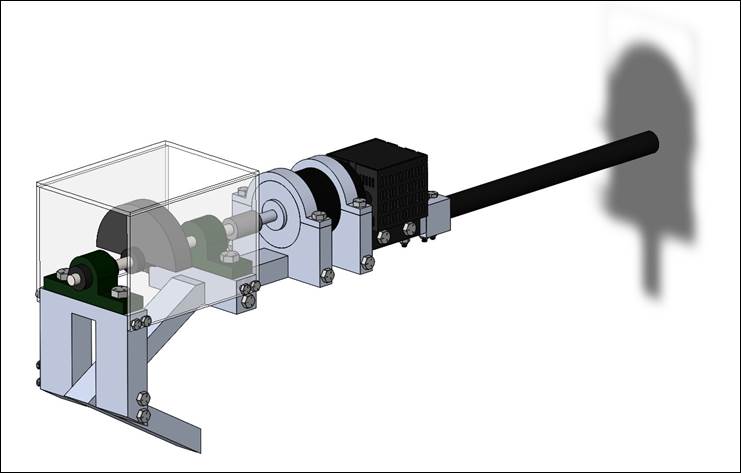

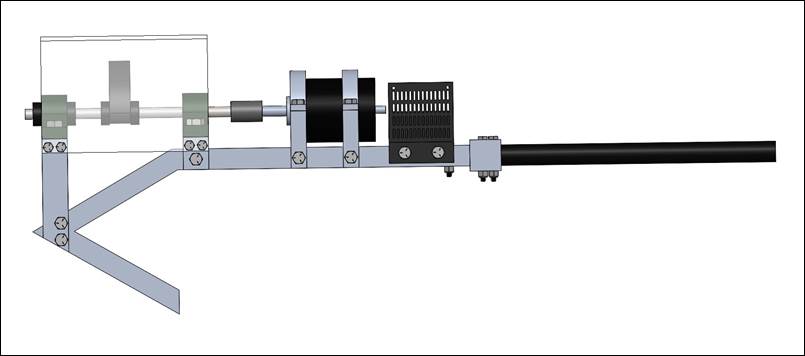

Figure 21 - Motor Assembly Model |

|

|

|

Figure 22 - Motor Assembly Model

(Side View) |

The two figures above depict the

motor assembly configuration developed on SolidWorks. This model gives the team

an idea of how the motor, offset mass, and pillow blocks will be positioned on

the device. In this case, two pillow blocks are mounted on each side of the

offset mass. This will provide additional support to the system as the offset

mass is rotating and generating a force.

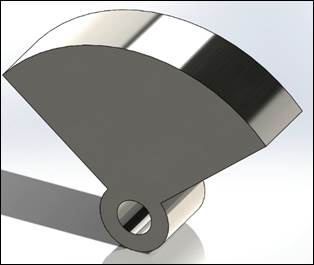

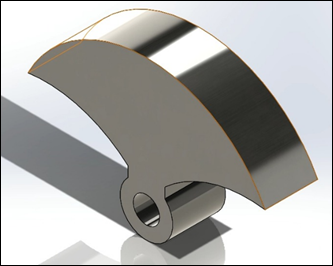

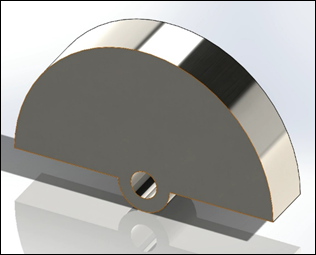

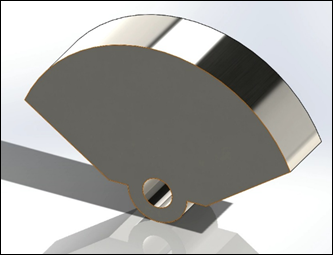

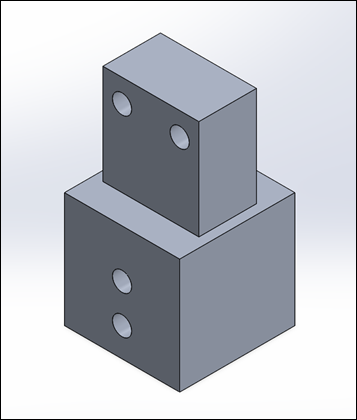

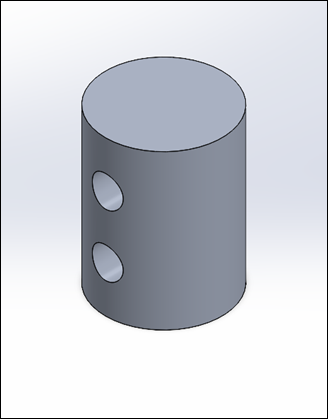

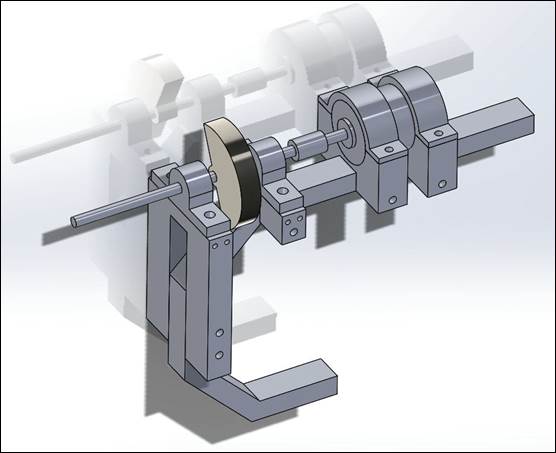

The team designed several different

offset mass shapes on SolidWorks to evaluate how their shape affects the

generated force. Since the generated force depends on the mass of the object

and the distance between the axis of rotation (center of circle) and its center

of mass, we wanted to see which mass will generate the largest force (given

certain constraints). After conducting some calculations, we determined offset

mass 3 to be our best option. Although offset mass 3 didn't have the largest

eccentricity, its mass was large enough to generate the largest force of the

sample offset masses (given constant rotational speed).

|

|

|

|

Figure 23 - Offset Mass 1 |

Figure 24 - Offset Mass 2 |

|

|

|

|

Figure 25 - Offset Mass 3 |

Figure 26 - Offset Mass 4 |

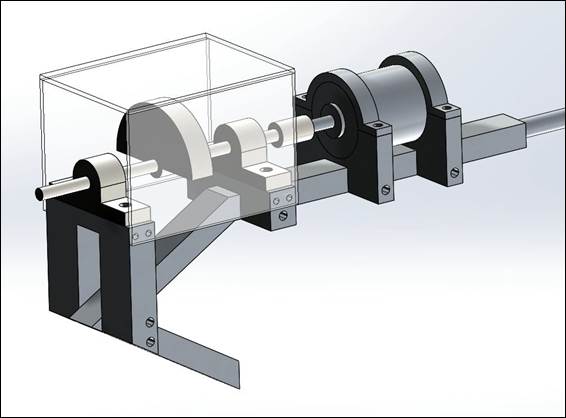

Figure

27 - Hook Assembly Model (Version 1)

Figure 27 shows our first SolidWorks

Hook Assembly model. This gave the team a better understanding of how each

component will be mounted to work as a system. The SolidWorks components

previously designed were modified to the dimensions of the materials purchased

(DC Motor, Pillow Blocks, Shaft, & Coupling). To attach the motor and

pillow blocks to the hook, different mounts were designed. These were

relatively simple mounts that can be bolted onto the hook (removable). The hook

shown above was designed by the previous team. Although this design looked

promising to us, discussions with our faculty adviser made us realize that the

hook had a fixed width and was not compatible with branches of various sizes.

This geometry is not ideal since the hook is only able to attach to branches of

one specific size. In addition, the hook was made of solid aluminum which meant

it would be heavy. The team decided it was best to redesign the hook based on

measurements (circumference/diameter) from actual mesquite tree branches as

well as perform the appropriate analysis to see if a hollow hook would be safe

to implement (can it handle the expected forces/vibration).

Figure

28 - Hook Assembly Model (Version 2)

After visiting Zinnia Park and

taking measurements of several mesquite tree branches, we came up with a range

of diameters for the hook to attach to. We also performed a finite element

analysis on SolidWorks and determined that a hollow aluminum hook frame should

be ale to withstand the generated forces. Therefore,

we decided to implement a hollow, tapered hook into our design. This new hook

will be significantly lighter and capable of latching onto branches of various

sizes. The figure above shows our updated our hook assembly model. Some changes

include implementing the newly designed tapered, hollow hook, reducing the

thickness of the motor mounts (top and bottom), modifying the upper pillow

block mount (to fit redesigned hook), and surrounding the offset mass with a

polycarbonate case (safety). Again, this SolidWorks model gives the team a

better understanding of how each component will be put together to function as

one. The team will now work to manufacture and assemble the harvester based on

this design.

Early Experiments

Since this is a continued project,

the team found that it was best to perform experiments to gather appropriate

data for analysis. Using a motor with an offset mass (rotating unbalance used

in massaging chairs), a mesquite tree, harvested mesquite beans, and a power

supply, the team was able to put together a series of experiments that helped

us understand how the mesquite beans are excited as well as the different frequencies

of excitation. Ideally, we want to match the driving frequency with the natural

frequency of the mesquite beans. Below are some of the experimental setups we

were able to carry out.

Experiment 1:

|

Figure 29 - Rotating Unbalance

attached to Branch |

Figure 30 - Mesquite Beans

attached to Subbranches (via rubber bands) |

Due to not having possession of a

mesquite branch at the time, experiment was performed on oak tree branch. Motor

was zip-tied to branch end. Mesquite beans were attached to branch with rubber

bands. Beans were excited through a range of frequencies (via motor voltage

adjustment). Response of mesquite beans was observed.

Experiment 2:

|

Figure 31 - Mesquite Beans

attached to Subbranches (via rubber bands). Rubber Bands fixed to subbranch

with tape. |

The second experiment was performed

on a mesquite tree branch. Because beans (with rubber band) tended to slide

down the subbranch during excitation, rubber bands were now fixed to subbranch

through tape. This way, the initial conditions of the beans remain constant.

Experiment was performed through same range of voltages (motor speeds).

Excitation of beans was recorded for close observation.

Experiment 3:

|

Figure 32 - Rotating Unbalance

attached to Hook |

Figure 33 - Mesquite Beans

attached to Subbranches (via hot glue) |

For our latest experiment, the

mesquite beans were now attached to the subbranch with hot glue. This was to

try to limit the influence of the rubber bands on the response of the mesquite

beans. In addition, the motor was attached to a hook to examine how the beans

will respond to more realistic conditions. With access to a tachometer, we

measured the rotational speed of the motor throughout the range of operating

voltages. The team also investigated how the position of the motor on the hook

changed the direction of vibration and thus how the mesquite beans are excited.

Prototype 1 - After testing, a prototype of the hook and motor

was built. This prototype serves to help the team in determining the proper

dimensions and orientation of each of the components that will be used in the

final design. The orientation of the offset mass is positioned so that the

vibration causes bending motion in the mesquite beans.

|

|

|

|

Figure 34 - Hook

Prototype |

Figure 35 - Hook

Prototype (Close Up) |

CHECK

OUT our Prototype 1

Video. See Video Below!

Motor

Assembly 1 & 2 (CAD):

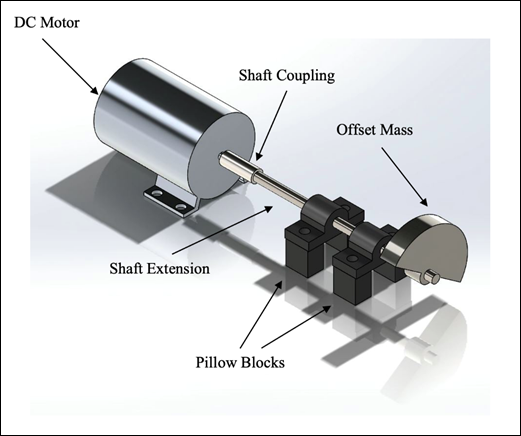

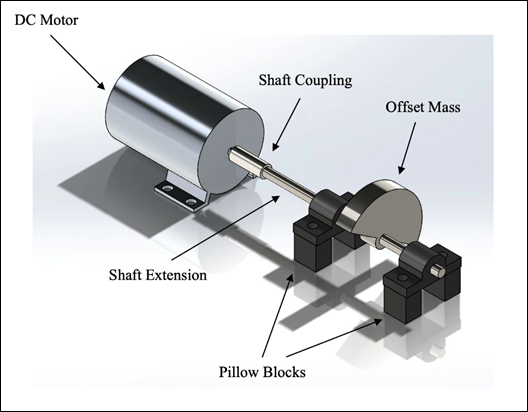

Creating the following motor

assembly models on solid works gives the team a general idea of the configuration

that will be mounted on the side of the extender pole. The components involved

in this assembly include a DC Motor, a Shaft Coupling, a Shaft Extension, Two

Pillow Blocks, and an Offset Mass. The pillow blocks are implemented to bear the

forces generated by the rotating offset mass. The motor assembly will be

mounted in such a way that the offset mass is positioned alongside the tree

branch. This way, the force generated is transmitted directly towards the

branch the hook is attached to. The placement of the offset mass is subject to

change. Whether it stays on the outside of both pillow blocks or if it is repositioned between the two pillow blocks will

depend on the static analysis (solid mechanics) performed (see Design Process

Page).

Figure

36 - Motor Assembly 1

Figure

37 - Motor Assembly 2

Rotating

Unbalance Summary:

Governing Equation: ![]()

Generated Force: ![]()

Parameters:

(![]() ) - mass of the system (kg)

) - mass of the system (kg)

(![]() ) - damping coefficient (kg/s)

) - damping coefficient (kg/s)

(![]() ) - stiffness of the system (kg/s2)

) - stiffness of the system (kg/s2)

(![]() ) - offset (unbalance) mass (kg)

) - offset (unbalance) mass (kg)

(![]() ) - eccentricity (m)

) - eccentricity (m)

(![]() ) - driving frequency (rad/s)

) - driving frequency (rad/s)

t - time (sec)

(![]() ) - translational acceleration (m/s2)

) - translational acceleration (m/s2)

(![]() ) - translational velocity (m/s)

) - translational velocity (m/s)

(![]() ) - translational displacement (m)

) - translational displacement (m)

Figure

38 - Rotating Unbalance Diagram

On the left side of the governing

equation, we have the mass of the overall system (![]() ), the damping coefficient (

), the damping coefficient (![]() ), and the stiffness of the system (

), and the stiffness of the system (![]() . Here, it's important to mention

that the "system" that is represented in this project is the hook

that the motor assembly will be mounted on. Moreover, the (

. Here, it's important to mention

that the "system" that is represented in this project is the hook

that the motor assembly will be mounted on. Moreover, the (![]() ) represents the acceleration of the

system, (

) represents the acceleration of the

system, (![]() ) represents the velocity, and (

) represents the velocity, and (![]() ) represents the displacement of the

system.

) represents the displacement of the

system.

The right side of the governing

equation includes the mass of the rotating unbalance (![]() , the eccentricity (

, the eccentricity (![]() ) (distance from the axis of

rotation to the center of mass), and the driving frequency (

) (distance from the axis of

rotation to the center of mass), and the driving frequency (![]() ). Collectively, these parameters

make up the force magnitude, as shown above. The force magnitude is multiplied

by a sinusoidal function in which the period of oscillation is determined by

the driving frequency (time dependent function).

). Collectively, these parameters

make up the force magnitude, as shown above. The force magnitude is multiplied

by a sinusoidal function in which the period of oscillation is determined by

the driving frequency (time dependent function).

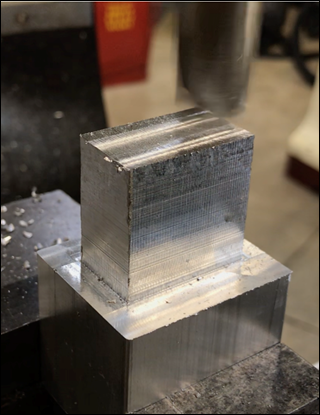

Prototype 2 - With new information and ideas, the team began working in

the machine shop to develop the second prototype. This version improves upon

the first one in several ways. The new prototype is mainly composed of aluminum

with the hook being composed of hollow aluminum tubing. The rotating unbalance

motor was replaced with a regular DC motor with a custom-made offset mass

attachment to induce vibrations. In addition to being more robust, it can

produce much stronger vibrations. It includes a speed controller which allows

the user to easily adjust the vibration frequency by using a dial.

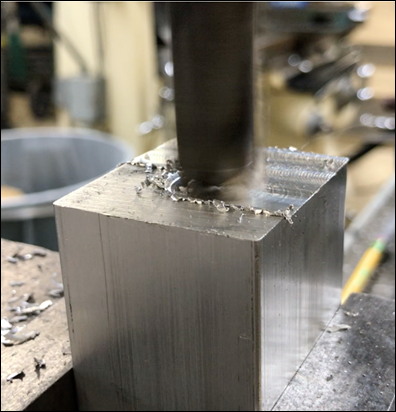

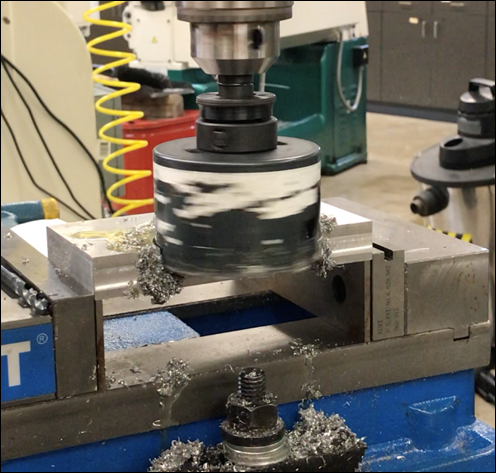

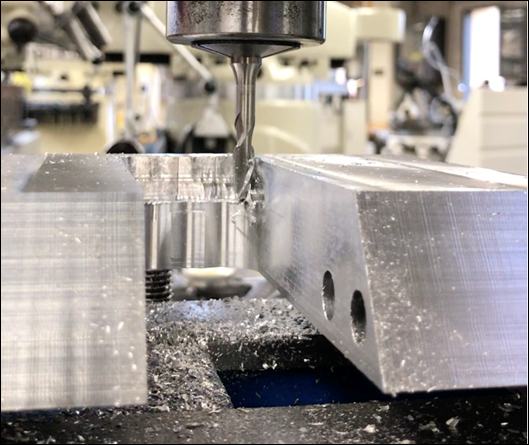

Manufacturing

Procedure:

1.

Mill

all the metal blocks to its border size (rectangular prisms), then mill out all

the corners and right angles of the block pieces.

2.

Drill

all the holes of all the pieces with the smallest diameter specified in the

blueprints, then all the holes with the next biggest diameter, and so on (until

all holes of all sizes are drilled).

3.

Apply

the same practice with the holes that require threading (use tap drills and

taps).

4.

Finally,

angle the Milling machine to manufacture the slanted geometries of the

appropriate metal pieces.

5.

Other

pieces with curved geometries were first subject to the vertical bandsaw and

then the belt sander.

Figure 39 - Cutting 3" Hole

Figure 40 - Lower Motor Mounts

Figure 41 - Shaping Outer Curvature

Figure 42 - Upper Motor Mounts

Figure 43 - Using Tap to Create Threads

Figure 44 - Lower Pillow Block

Mount

Figure 45 - Trimming Slot Edges on

Upper Pillow Block Mount

Figure 46 - Hook Frame

Figure 47 - Ben (Left) & Paul (Right)

Milling

Figure 48 - Milling Offset Mass

Figure 49 - Ben (Left) & Miguel (Right)

Milling

Assembly Procedure:

1.

Align

and screw the lower motor mounts to the main hook frame.

2.

Align

and screw the pillow block mounts to the main hook frame.

3.

Place

the motor securely on top of the lower motor mounts, making sure that the wires

from the motor don't get crushed/pressed against.

4.

Make

sure the coupler is locked; this will connect the two shafts securely from the

motor.

5.

Apply

the upper motor mounts and screw them to a tight fit on the lower motor mounts.

The motor should then be stable and not slide from its position.

6.

Slide

in the lower pillow block into the shaft and on top of its respective mount.

7.

Screw

it to keep it in place with the adjustable wrench.

8.

Insert

the first clamp that will be next to the mass, then the offset mass itself,

then the other clamp on the other side of the mass.

9.

Make

sure that the clamps are right next to the offset mass and use the Allen wrench

to lock them in place.

10.

Make

sure the hole of the offset mass is aligned with the hole in the shaft and use

a screw to tighten it in place. This allows the torque to be transmitted.

11.

Slide

in the upper pillow block through the shaft and on top of its respective mount.

12.

Screw

it securely using the adjustable wrench.

13.

Hover

the polycarbonate casing around the offset mass and screw it onto the assembly

with an adjustable wrench.

Figure 50 - Assembled Hook without Case

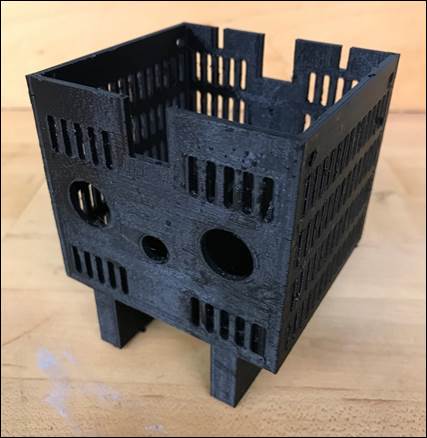

3D Printing

After assembling all the

mechanical components of the hook device, the team shifted its focus towards

the electronics. The team designed a battery case that will house both

batteries and be mounted directly behind the motor. In addition, to control the

speed of the motor, a speed controller will be used. The speed controller must

be easy to use and not have wires exposed. The team therefore decided to design

a case for the speed controller that will house the speed controller along with

the ON/OFF button and potentiometer. The speed controller will be mounted on

the pole to allow the user access to the controls.

Figure 51 - Battery Case

Figure 52 - Speed Controller inside Case

CHECK

OUT

the Manufacturing Process. See Video Below.

CHECK

OUT

the 3D Printing Process. See Video Below.

Field

Test at Cappadona Ranch

Figure

53 - Team Setting Up Device

After each individual component was

assembled onto the hook/pole, the team conducted a field-test. Our designed

experiments were cut short due to the pole breaking off from the hook.

Figure 54 - Team Discussing Broken Device

Minimal data was collected. Team is

looking to modify design to make it more rugged. Wiring and controller came

loose multiple times during experiments. We noticed that the pole shook a lot

during experiments and was not needed once hook was attached to branch. Team is

therefore considering having a removable pole or removing the pole from the

design. In addition, we intend on trying a different approach to harvesting.

Instead of exciting the beans at their natural frequency, we will look to

excite the branch at its natural frequency and evaluate the results. We are

continuing to work on the device to make sure it is effective in harvesting mesquite

beans.

Figure 55 - Team Attaching Hook to Mesquite

Branch

Repair

|

|

|

Figure

56 - Pole-Hook Connection Failure |

Although the team was mildly upset by this setback, it

was a valuable moment for the team as we were able to identify a

weakness in the hook assembly design. Up until this point, most of our physical

simulation test runs from SolidWorks were used to find the stresses and

deflections that the hook frame experienced; such simulation runs were

not performed for the pole yet. After the hook-pole interface broke, the team

began discussion pertaining to the cause of failure. It was agreed

that the most probable cause of failure was a combination of fatigue and the

pole reaching its natural frequency. We followed up this discussion by

brainstorming different ways we could repair the harvester. Several ideas

were proposed to fix the hook-pole interface including a welded joint

and an aluminum hook insert fastened by bolts. The team decided to move forward

with a flagpole as the pole that will attach to the hook assembly. The flagpole

is made of stainless steel and is adjustable in length (5 separate pole

sections). The team believes adjusting the length of the flagpole will help us

avoid the natural frequency of the pole. In addition, shortening the length of

the pole will make the device much easier to handle. The team began redesigning

the hook-pole junction to work with the new pole.

Redesign of Hook-Pole

Connection

|

|

|

|

Figure 57 - Connector Model |

Figure 58 - Filling Model |

The connector is designed

to allow a hollow steel tube to be bolted on. A cylindrical filler will be

inserted inside the top end of the hollow flagpole. The aluminum filler is

used to provide extra support to the flagpole as it is bolted onto the

connector piece. This design improves upon the previous design by providing

a more rigid connection between the pole and the hook assembly. Previously,

roll pins were used to fix the pole in place. This time, two bolts will be used

to secure the pole to the bottom portion of the connector.

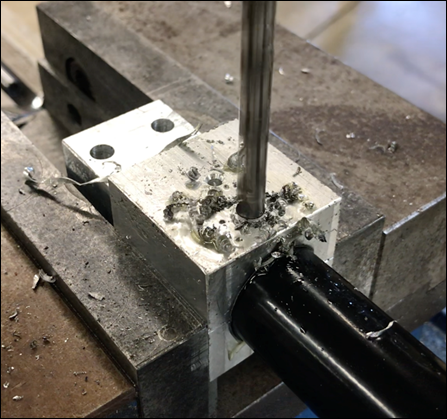

Return to the Machine Shop

After performing static

and frequency studies on the newly designed hook-pole interface, the team

returned to the machine shop to machine the necessary components. Considering

the team had machined similar components before, this repair process was

relatively straightforward. We used the mill to face and trim the connector piece

to spec. The connector piece will be inserted into the bottom end of the hook and

fixed in place using two bolts. A 1 inch hole was

drilled into the bottom side of the connector piece to allow the flagpole to be

inserted.

|

|

|

|

Figure

59 - Facing Connector |

Figure

60 - Trimming Connector |

|

|

|

Figure 61 - Drilling

1-inch Hole |

The filler piece was

machined using the lathe. Since it had been a while since the team had worked

with a lathe, we were guided by one of the machine shop assistants. Once we had

gotten refamiliarized with the lathe, we machined the filler to spec. The

filler piece had to be smaller in size to fit inside the hollow steel tube

(flagpole). The filler is 0.94 inches in diameter and 1.25 inches in length. Once

the filler material was reduced to its proper size, we pressed it inside the

top end of the first flagpole section (snug fit). Again, this will serve as

additional material for the bolts that will run through the flagpole section to

hang onto. Without the filler, the bolts would only be grabbing on to the outer

(thin) walls of the pole, which won't be very secure (creates stress

concentration).

|

|

|

|

Figure 62 - Using Lathe

to Machine Filler |

Figure 63 - Filler

Inside Pole |

|

|

|

|

Figure 64 - Pole with

Filler inside Connector |

Figure 65 - Drilling

Holes inside Connector |

The team then inserted

the pole (with the filler) inside the connector and drilled two 1/4"

holes. Two bolts will be used to secure the pole (together with the filler) to

the connector piece. The pole-connector sub-assembly was then attached to the

hook frame using two bolts. Once secured, the device gained the additional

function of being able to attach and remove pole sections. Although this new

design is similar to the previous one, we believe this

connection will be much stronger and sturdier. The two figures below depict the

harvester after it had been fully repaired. Now that the device was completely

repaired, field testing could resume.

|

|

|

|

Figure 66 - Connector

attached to Pole and Hook |

Figure 67 - Completed

Repair of Harvester |

Field Tests at Park (Repaired Hook)

After repairing the hook, we visited Zinnia Park a couple of times

to test our new, fixed prototype. Our first visit consisted of mostly

observational data; recording which frequencies excited the mesquite beans the

most. This gave us an idea of what range of frequencies worked best. On our

next visit, we used an accelerometer phone app to measure the acceleration experienced

by the branches. The acceleration data obtained was then used to estimate the

forces experienced by the branch during operation. This set of experiments are

critical to evaluating the performance of the harvester.

Here is an

outline of the experiments we carried out:

First, we had the assembly all attached together, with the

polycarbonate casing and the fixed pole connection (1st section). Then,

we attached the hook frame around the first branch. For the lower

branches, we just left it there with the default 1st stainless steel

pole section attached to the frame. For the longer branches

we attached the other sections by screwing them from the 1st one, depending on

how elevated the branch was from the ground. The ability to attach and remove

sections of the pole prevented the pole from reaching its natural frequency

during testing. This is a clear improvement over the 1st design which

prevents the pole from failing in the same manner. While the prototype was

running, we had someone designated to monitor, and lightly touch, the base of

the lowest pole extension section, in order to prevent

any possibly tipping over of the hook from the branch. The main difference in operating the device from the 1st field

test is that now the speed could be controlled from a short distance away. The

speed controller was connected to the hook via the umbilical cord. This made it

easier to control because the dial would not shake with the hook. It is

also safer for the user. We tested at varying branches

at a steady sweep of frequencies. We

went at intervals of increasing the percent power 5 percent each time, closely

observing the movement of the branches.

|

|

|

Figure 68 - Hook

Ganging on Branch |

|

|

|

|

Figure 69 - Harvester

Shaking Branch |

Figure 70 - Controlling

Device from a Distance |

Table 1 - Optimal Frequencies for

Branch Displacement by Observation

|

Branch |

Circumference (in.) |

Diameter (in.) |

Length (in.) |

Voltage Range (% Power) |

Frequency (Hz) |

|

1 |

8 |

2.546 |

110 |

50-55 |

8.253 |

|

2 |

9.25 |

2.944 |

150 |

45-55 |

7.37 |

|

3 |

7.875 |

2.507 |

107 |

30-40 |

3.95-5.576 |

|

4 |

6.25 |

1.989 |

75 |

30-40 |

3.95-5.576 |

|

5 |

10.75 |

3.422 |

90 |

32-35 |

4.6-5.576 |

CHECK OUT our Repair Process and Field Testing.

See Video Below!

|

|

|

|

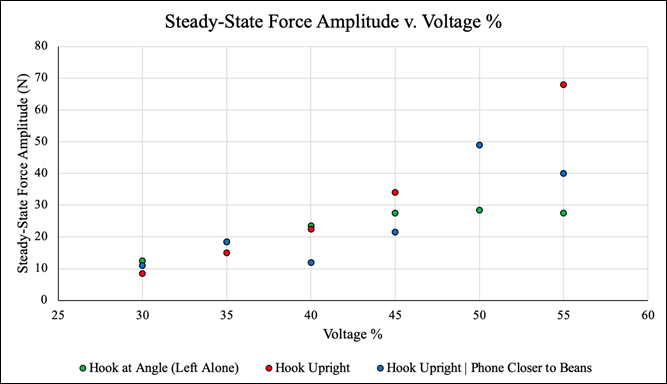

Figure 71 - Experimental Set Up 1

(Hook at Angle) |

Figure 72 - Experimental Set Up 3

(Phone Closer to Beans) |

Eventually, we got to our final experiment, where

we were able to obtain more concrete, quantitative data (rather than just

eyeballing the results). We did this using an

accelerometer app on a phone that would be able to display real-time

graphical results of the x-, y-, and z-displacements of the phone. For each branch that we wanted to test, we taped the

phone, with the app ready to run at the outer reaches of the branch. Before running each test, we measured the approximate

circumference of the branch near the taped region and the horizontal distance

from the hook's grip to the phone's location. We then ran the test starting at 30 percent power

(with the phone accelerometer also being active at this time), let it run for

15 seconds, then stopped the prototype and stopped the measurements the

phone took. The data was

then exported, and we prepared to increase the percentage

power for the next run. For the

next run, we went up by 5 percent and then repeated the process that was

done for the first run; this went on for several steps.

|

|

|

Figure 73 -

Steady-State Force Amplitude v. Voltage % Plot |

The results of the second

field test are summarized in the graph above. It is shown that

as the voltage percentage increases while operating the device

with the hook upright, the steady-state force amplitude increases linearly. The

same is not true for when the device is closer to the beans, as the

amplitude seems to fluctuate as voltage increases. Furthermore, in both cases,

the upright hook produces a greater amplitude than the angled hook at

higher voltages.

Although this set of data does not give us a

direct answer regarding the effectiveness of the device, we believe a

correlation can be made between the acceleration and the displacement of the

branches. This relationship should result in a more accurate way of evaluating

the device's performance. Still, we believe the experiments conducted helped us

understand what range of frequencies and position of the harvester are ideal.

FINAL PRODUCT

After much work, this is our final

product.

|

|

|

Figure 74 - Mechanical Mesquite

Bean Harvester |

|

|

|

Figure 75 - Mechanical Mesquite

Bean Harvester Model |

Pictured above is our final

SolidWorks model. This model includes some our latest design changes (connector,

filling, steel flagpole) as well as other components not previously included

(battery case, shaft collars, bolts, nuts). The team believes having a detailed

model of the device is very important. It allows us to demonstrate what

components make up the device and how each component works together to function

as one.

The following figure shows the

different components of the device.

|

|

|

Figure

76 - Mechanical Mesquite Bean Harvester Model (Side View) |

By creating a detailed SolidWorks

model of the Hook Assembly, the team was able to put together an assembly

manual that shows the user how to assemble the device step-by-step. This will

help guide the user throughout the assembly process and prevent any mistakes

from being made. In addition, this manual will reduce the time needed to assemble

the device. The assembly manual includes pictures of each step as well as lists

the components involved for each step. We also made an assembly video and a

written instruction manual to help aid the assembly process. The team believes the

combination of these three guides are important for the user to assemble the

device correctly.

Click HERE to view Assembly Manual.

Click HERE to view Written Instruction Manual.

CHECK OUT our Assembly Guide Video Below!

The team also made a simple rendered

animation of the Mechanical Mesquite Bean Harvester using Blender. The model

shown in the video below is based off the SolidWorks model. The model was

imported to Blender as an STL file, after which minor modifications were made

(added materials, lighting). The animation is a simple revolve around the

Mesquite Harvester. This animation allows the team to showcase an accurate

model of the device.

CHECK OUT our Mechanical Mesquite Bean

Harvester Animation Below!

Our project is a proof of concept

that requires further development. The team has laid out a plan regarding what

we believe should be done next to improve the device. These are some of the

pending items as well as things we think should be done differently:

o

Testing during

the mesquite bean harvesting season (May - August). While our device works as

intended, we would have liked to test it on mesquite trees that have ripe beans.

o

Implement new

battery-charging method. The current process involves

having to untie the battery wires and charging them separately. This is a long process considering the wires need to be

removed from the umbilical cord, which takes a while. We would have preferred

using a battery which could be easily charged without needing to disassemble a

portion of the wire tubing. The team believes replacing the battery pack with a

rechargeable internal battery, like the kind of rechargeable battery found in a

cell phone or laptop, would work better.

o

Try new methods

to excite mesquite beans. Perhaps a more direct approach to

harvesting mesquite beans would work better. Our

approach was to excite/harvest as many mesquite beans at once by transmitting

vibrations through the branches. However, there may be a more efficient and

productive way of harvesting mesquite beans by simply "raking" them

off the branches.

o

Try and see if

a wireless connection for controlling the volt percentage power could be

feasible. Wireless control would allow the user to

control the device from a safe distance away.

o

Possibly try

out a grip attached to a long, tensile cable that could possibly transmit

vibrations. This way of harvesting would involve a

tractor and some sort of attachment.

o

Use cameras

(slow-motion) to record motion of mesquite beans and come up

with amplitude-frequency response graph that estimates the natural

frequency of mesquite beans. Since the whole idea is to harvest mesquite beans,

it is best that we look carefully at how the mesquite beans respond to the

excitation induced (Do not rely too much on simple observation).

o

Reduce as much

weight as possible from harvester to allow for easier handling. Currently, the

harvester weighs just over 20 pounds. Making it lighter will make it easier to

carry around during harvesting.

o Since

everything in nature is nonlinear and mesquite trees are a very complex system,

the team believes a variety of frequencies may be used to cause mesquite beans

to reach their natural frequency. There is no one correct frequency to be

applied to every mesquite tree branch. Because the geometric and mechanical properties

of each mesquite branch is different, it affects how the beans respond to the

vibrations transmitted.

IN CONCLUSION

Our Senior Design experience:

Throughout Senior Design, the team

enjoyed collaborating with one another and working together to create a working

prototype. Our Senior Design project focused on developing an efficient harvesting technique

that will expedite the mesquite bean harvesting process and thus help

farmers/ranchers increase their mesquite bean yield and supply of mesquite bean

products. Although the device was not as effective at harvesting mesquite

beans as we'd hope, we believe the development of the mechanical mesquite bean

harvester is a critical step to creating an improved model. While further

testing of the device will need to be conducted to accurately assess its performance,

the team has helped pave the way towards solving the task at hand. We believe our

device will prove to be helpful in improving the efficiency of the mesquite

bean harvesting process, and with some more work, will ultimately aid farmers

by allowing them to harvest mesquite beans with greater efficiency than

hand-picking.

In

addition, working on this project was a valuable educational experience for us.

It gave us a lot of useful experience, such as hands-on machining and

troubleshooting, that will help us in our future engineering careers. This

project is an interesting bridge between the engineering and agricultural

disciplines. Getting the opportunity to work with the Cappadona family was a huge pleasure. The team learned

a lot about the importance of mesquite trees and mesquite beans. Moreover, we realized

the impact a mechanical harvester can have on the mesquite bean business. A

mesquite harvesting device will fundamentally change how the mesquite tree is

viewed and used. Knowledge of subjects outside of college engineering courses

is helpful. In the real world, most engineering problems are not covered in

college courses, and require a level of engineering experience and judgement to

solve. The mesquite harvester is a good example of this type of problem. The

experience gained while working on this project cannot be replaced by a typical

engineering course.

The team considers this a very important problem

that we as engineers can help solve. We strongly believe this

project can continue to progress and improve based on our work.

REFERENCES

[1] Ramos, Mary. "The Ubiquitous

Mesquite, " Texas Almanac, Texas State Historical Association

(TSHA), 2007, https://texasalmanac.com/topics/environment/ubiquitous-mesquite

[2] "Plant Database - Prosopis glandulosa, " Lady

Bird Johnson Wildflower Center, 6 November 2015, https://www.wildflower.org/plants/result.php?id_plant=prgl2

[3] "The Amazing Mesquite Tree, " Cappadona Ranch, 7 March 2017, https://cappadonaranch.com/blogs/blogs/the-amazing-mesquite-tree

[4] "Mesquite - The Wonder Tree, " An Eye

for Texas, 29 March 2011, https://aneyefortexas.wordpress.com/2011/03/29/mesquite-the-wonder-tree/

[5] DuHamel, J. "Mesquite

Trees provide Food, Fuel, Medicine, & More, " Arizona

Daily Independent News Network, 7 July 2013, https://arizonadailyindependent.com/2013/07/07/mesquite-trees-provide-food-fuel-medicine-and-more/

[6] "Rotating Unbalance, " Virtual Labs -

An MHRD Govt of India Initiative, http://mdmv-nitk.vlabs.ac.in/exp6/index.html

[7] Niklas, K.J., 1992, Plant

Biomechanics - An Engineering Approach to Plant Form and Function, The

University of Chicago Press.

[8] James, K.R., Dahle, G.A., Grabosky, J., Kane, B., Detter,

A., 2014, Tree Biomechanics Literature Review: Dynamics, Arboriculture &

Urban Forestry 40(1), 1-15.

[9] Dargahi, M., Newson, T., Moore,

J.R., 2020, A Numerical Approach to Estimate Natural Frequency of Trees with

Variable Properties, MDPI Forests 11, 1-21.

[10] 2010, Frequency Response of Trees, Dept. of Civil and

Environmental Engineering MIT, 1-31.

[11] Baker, C.J., 1997, Measurements of the Natural Frequencies of

Trees, Journal of Experimental Botany 48(310), 1125-1132.

[12] Ganji, H.D., Ganji,

S.S., Ganji, D.D., Vaseghi,

F., 2011, Analysis of Nonlinear Structural Dynamics and Resonance in Trees, Shock

and Vibration 19, 609-617.

[13] Loghavi, M., Khorsandi,

F., Souri, S., 2011, The Effects of Shaking Frequency

and Amplitude on Vibratory Harvesting of Almond, ASABE.

[14] Ni, H., Zhang, J., Zhao, N., Wang, C., Lv,

S., Ren, F., Wang, X., 2019, Design on the Winter Jujubes Harvesting and

Sorting Device, MDPI Applied Sciences 9, 1-17.

[15] James, K.R., Haritos, N., Ades, P.K., 2006, Mechanical

Stability of Trees under Dynamic Loads, American Journal of Botany 93(10),

1522-1530.

[16] Polat, R., Gezer, I., Guner, M., Dursun, E., Erdogan,

D., Bilim, H.C., 2006, Mechanical Harvesting of

Pistachio Nuts, Journal of Food Engineering 79, 1131-1135.

We went through a meticulous design

process to arrive to the final solution. The information in this page is a

summary intended for the general public.

To learn about the project details, visit the DESIGN PROCESS Page.

To

obtain access Click HERE.

We would like to recognize and

thank several people whose help was critical to the team's success.

Dr. Noe Vargas (Senior Design

II Professor) - Guided team

throughout Senior Design, gave us advice on several different aspects of the

project, and provided us access to the Makerspace during the build stage.

Dr. Arturo Fuentes (Faculty

Advisor) - Regular feedback

and engineering advice regarding mesquite harvester. Constant support

throughout the project. Always gave us his thoughts on our proposed ideas and

suggested we try different methods to excite the mesquite beans.

Dr. Joanne Rampersad-Ammons

(Faculty Advisor) - Regular feedback

and information regarding mesquite harvester. Helped us understand the importance of

this project and the impact it can have.

Mr. Gregory Potter (Senior

Design II Assistant Professor) -

Advice for improving prototype.

Mr. Hector Arteaga (Machine

Shop Technician) - Machine shop

training and general help throughout

manufacturing process. Gave us his thoughts regarding different ways to

manufacture certain components. Helped the team a lot during build stage and

got the team involved with machining.

Mr. Jose Sanchez (Mechanical

Engineering Professor) - TIG

welded aluminum hook for the team.

Cappadona Family - Helped team by showing us the mesquite bean harvesting

process and how they process the beans to make different products. Showed us

around their ranch and allowed us to test our device there. We had lots of fun

and learned a lot from them.