UTRGV

/ COLLEGE

OF ENGINEERING AND COMPUTER SCIENCE / MECHANICAL

ENGINEERING DEPARTMENT

(Index

Page: General Audience)

|

SDI Students (L-R) |

·

Israel Falcon ·

Alejandro Garcia · Sabrina Dougherty · Jacob Gil |

|

Faculty Advisor(s) |

· Dr. Joanne Rampersad-Ammons · Dr. Horacio Vasquez |

|

Course Instructors |

· Dr. Noe Vargas Hernandez · Mr. Greg Potter |

|

College of Business and Entrepreneurship Collaboration |

Dr. Sylvia Robles (Instructor) ·

Andy Garcia ·

Nicolas Perez ·

Matthew Woodlee ·

Sarah Loya |

WHAT

IS THE PROBLEM WE ARE TRYING TO SOLVE?

WHY

IS THIS PROBLEM IMPORTANT?

LEARN

MORE ABOUT OUR DESIGN PROCESS

Welcome! We are team #7 “007”. We are Sabrina Dougherty, Israel Falcon, Alejandro Garcia, Jacob Gil, and Reyes Mendoza. We have been working on this project for the entire Spring 2021 semester, and we will continue to work on it on the Fall 2021 semester. Our project is titled “The Bee Project,” and the problem we are tackling is the low number of apiaries in the RGV region due to lack of interest and the difficulty of getting started in beekeeping. We have designed a device that allows aspiring beekeepers to get started in this activity by monitoring the weight of their beehive. Important information can be gathered from the weight of a beehive such as when the honey produced in their hive is ready to be harvested. We hope you enjoy this project as much as we have enjoyed working on it. Index Welcome Movie

In about

30 years our population will increase by 30%. There will be a greater need for

more food to feed everyone, and the current farmers are an older generation

that will not be active during that time. Further, the younger generation is not

becoming as involved in farming to balance the decline. In the RGV, beekeeping is a farming

activity that needs to be further developed to increase the bee population in

the region. Currently, the number of bee farms

in the area is substantially low in comparison to the future growth in

population due to the lack of people getting involved in this activity. In

order to foment upcoming bee farming, we are seeking to develop a product that

enables people without experience in this activity to obtain an easy-to-use

solution that can get them started in bee keeping.

Figure 1. - A depiction of a

beekeeper and the type of beehive used for our project.

To better understand the problem, we

have been conducting background research on the topic, and from this background

we have learned the following:

· Bees present a complex behavior which

must be acknowledged by the beekeepers for them to efficiently interact with

the bees. Bees have a well-defined and structured society based on work and

protection of their queen.

· Knowing the weight of a beehive can

reveal vital information regarding the overall state of the honey being

produced and the bees inside the beehive.

· Different components that interact

with the beehive, such as the bees, honey, and external factors affect the

total weight of the beehive, which can amount to a total of around 300 lbs in

some cases.

· Current beehives in use include the

Langstroth beehive, which is a customizable design made up of 8 to 10 frames and

are (mainly) made of wood. These are the most used beehives in North America.

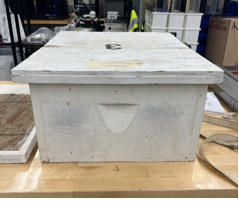

Figure 2. - Two displays of the Langstroth

beehive

· Currently, bee farming depends mainly

on the experience of the beekeepers since there are not many commercially

available resources that aid the process.

· Due to the weight of the beehive, the

most non-invasive & efficient way to weigh the beehives is by resting them

on top of a device that is similar to a floor scale.

· Regulations in the United States

regarding bee farming is mainly focused on the interstate commerce of bees to

prevent the introduction of certain species into environments where they should

not be.

· Animal rights activist groups advocate

for the ethical treatment of bees in bee farming; therefore, our device must

not interfere substantially with bees and their immediate environment.

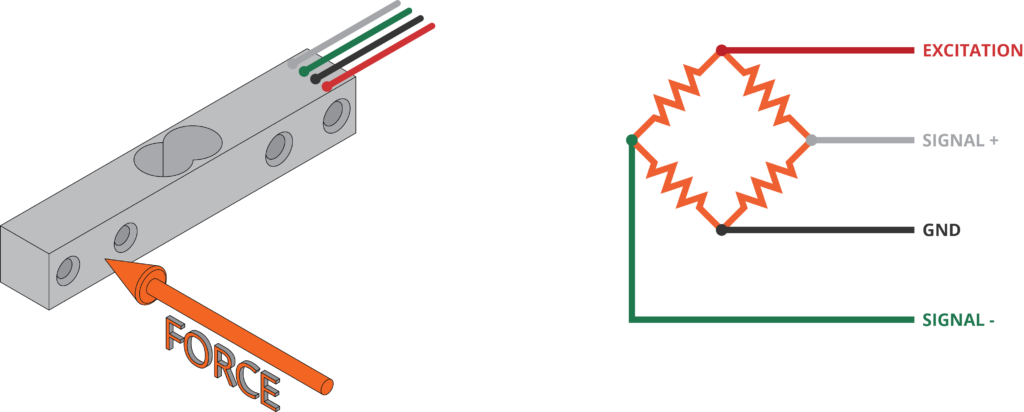

· Load cells are force transducers that

convert the force exerted on them into electrical signals. These devices are

the ones responsible for providing weight measurement readings caused by the compression

experienced on the base of the scale by being in contact with the beehive.

There is a great variety of load cells that serve different purposes depending

on specific conditions under which they operate.

Figure 3. - A single point load cell and

a simple model of the electrical circuit

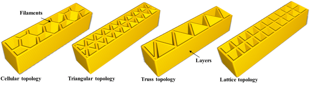

· The use of a corrugated structure provides

an efficient alternative to reduce the amount of material used in the

development of our device while giving it a stable platform.

Figure 4. - Four different styles of

corrugating/infill structures

· Current solutions similar to our

product include the “Solution Bee”, which is a device that collects information

such as the weight and temperature in the beehive and stores it for monitoring

of the beehive.

Figure 5. - Solution Bee’s product

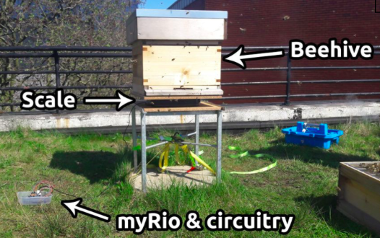

· Another solution to the problem is a project

known as “Weight my Bees,” which is a similar idea to both “Solution Bee” and

our product. However, this is not commercially available since it is used in

research to aid in finding a solution to the Colony Collapse Disorder.

Figure 6. - A Senior Design project

similar to our solution

Our main motivation to work on this

bee farming project is the environmental impact embedded in the problem we are striking.

We believe that the potential negative impacts generated by the decrease in bee

population and bee farming could be detrimental to society, not only in the RGV

region, but it could also influence the entire population. The complexity of

this problem is not only embedded in the environmental effects it generates,

but it also poses economic problems and potentially social injustice in the

disparity of food distribution to certain vulnerable communities.

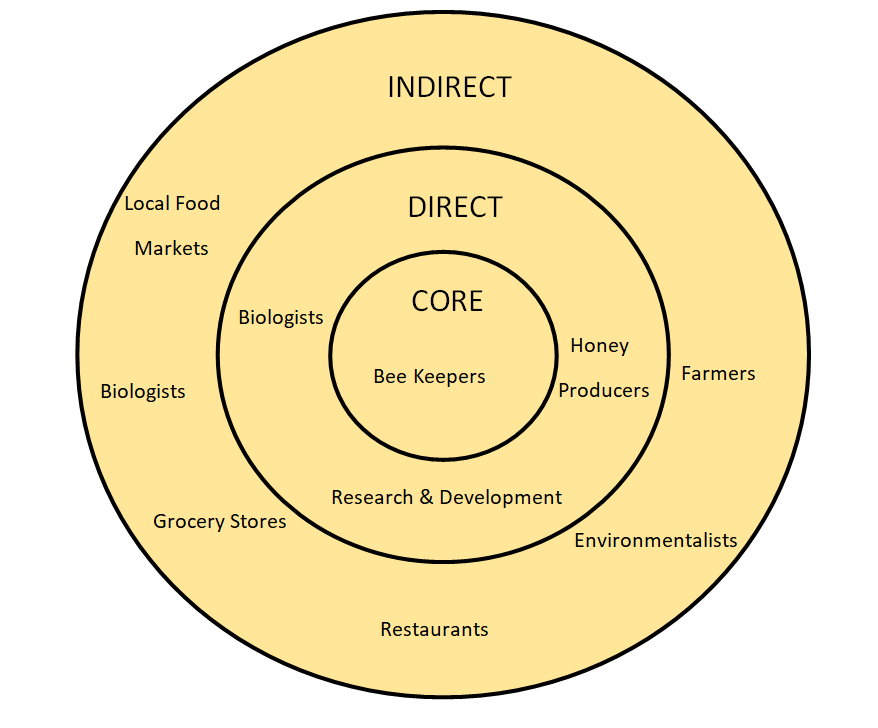

Several aspects of life are affected

by this issue, which is why there is a great variety of stakeholders in this

project. A graphical depiction of some of these is present in the Stakeholders’

Map below.

Figure 7. - Above is our

Stakeholders’ Map representing the different groups of people affected by the

problem we are trying to solve

“What we offer when compared

to our competitors is an easy and affordable way to start or continue

beekeeping. By providing a user-friendly and inexpensive product to help people

access vital information of their hives, this should incite their interest in

beekeeping.”

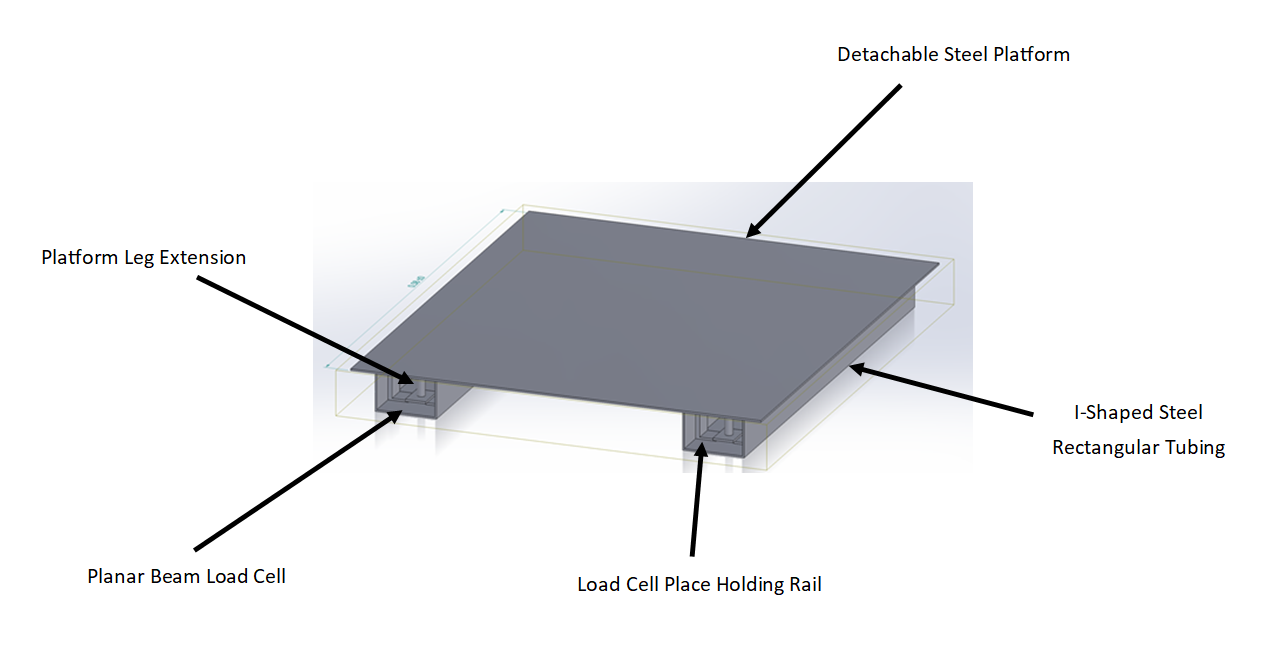

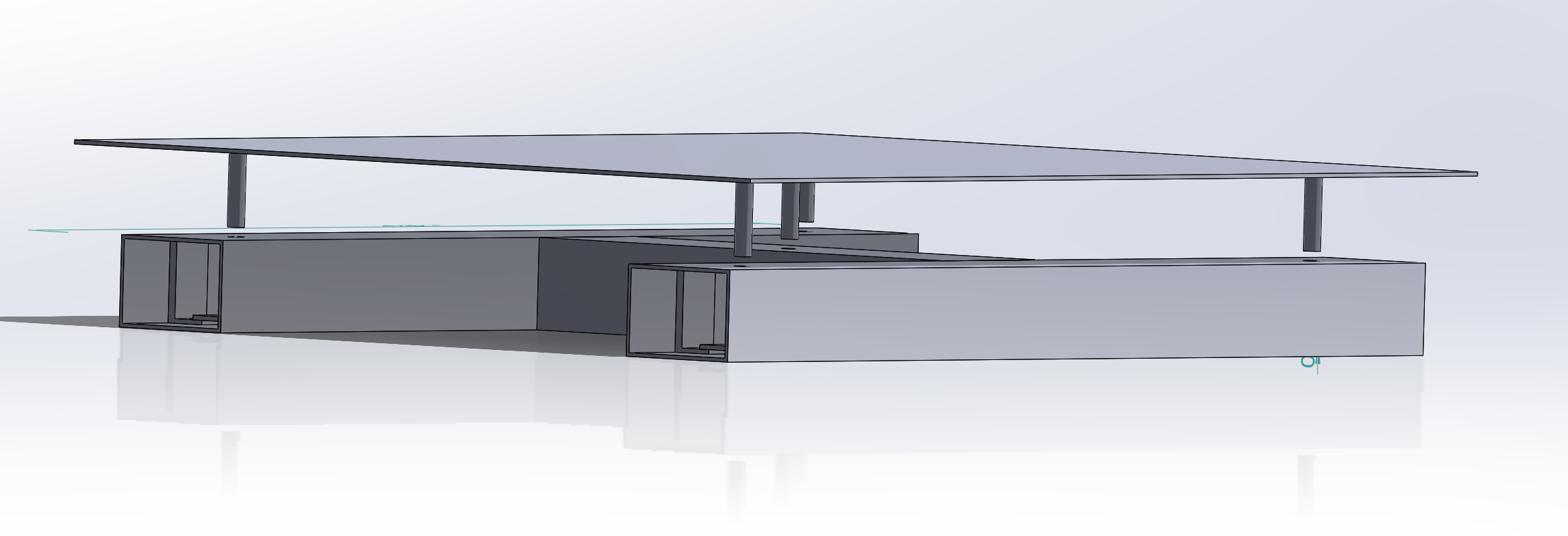

Figure 8. - Above is the original design of the beehive

scale

After understanding the problem in

depth, we explored various potential solutions and selected the best concept

(Pahl and Beitz, 1996).

Our product solution works by

utilizing the essential concepts behind a regular scale with certain

modifications that consider the specific needs of our problem. We have

developed a scale-type device that works alongside components such as a

Bluetooth module that allows the user to gain access to the weight measurements

of their beehive. Our device is powered by a rechargeable battery which allows

it to operate constantly and provide real time data to the user.

With the expected range of the beehive is between 300-500 pounds, a secure design is needed to ensure stability is achieved. Although several design concepts and bases were considered, a steel “I” rectangular tubing base with a top thin platform was selected.

Figure 9. - Above is an isometric view

of the original design

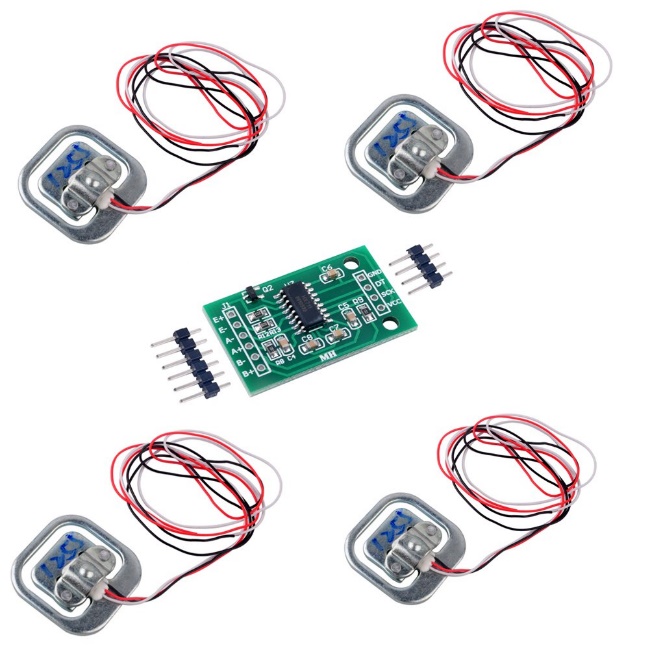

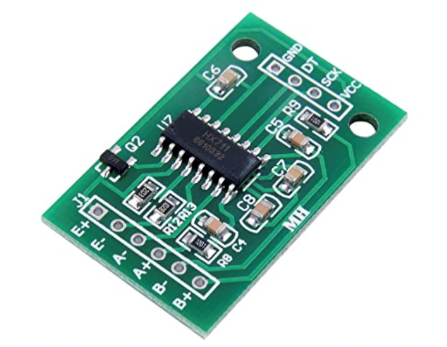

The weight measurement readings are

obtained using load cells. Several load cells are installed inside the

rectangular tubing, and these capture the weight from the platform and the

beehive on top of it. Additionally, the data collected by the different load

cells is summed up with the amplifier.

Figure 10. Load cells and an HX711 amplifier

are shown above

In order to ensure that the complete weight of

the beehive is directly on the loadcell, the platform can’t rest on the

rectangular tubing of the scale. If the platform is resting on the tubing, the

weight of the beehive would be distributed across the platform and tubing,

which would result in an inaccurate reading. To tackle this issue, the platform

will be “floating” on top of the tubing by having “legs” that will rest

directly on the load cells.

Figure 11. Early prototype showing

how the plate will rest on a pin that will directly hit the load cell

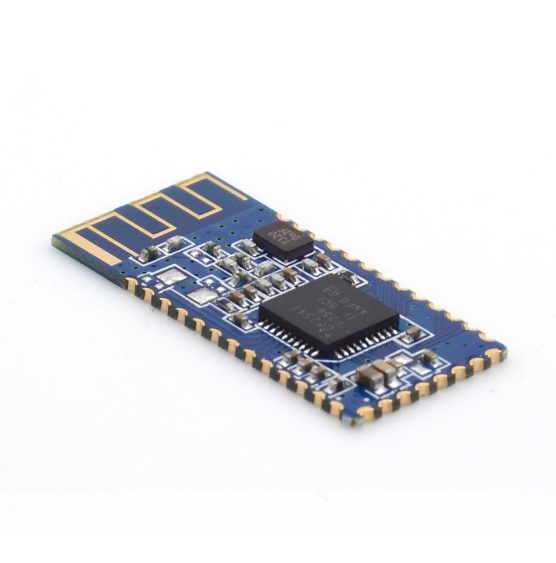

A Bluetooth module, amplifier, and a display

screen will be attached to an Arduino. The Arduino will receive the summed data

from the amplifier and send the information to the cellphone of the user and to

the display screen. This allows the user to receive the weight readings of

their beehive by looking directly at the display screen or through the data

sent directly to their phone.

Figure 12. The Bluetooth

module, amplifier, and display screen are shown above, respectively

Once we defined a clear solution idea

(i.e., concept), we applied our engineering knowledge to transform it into a

real product. These were some of the important design challenges and how we

approached each one of them:

·

Platform of device must not be directly attached to the base

To ensure the device provides accurate weight readings to the user, the load cell must receive the entirety of the load. Having the platform attached to the base would dissipate the load carried by the platform onto the base. Therefore, the load cells would receive an inaccurate reading. A platform that would not rest on the rectangular base is needed. A solution to this challenge would require the design to have a platform with “legs” (pins) that will connect to the load cells to remain lifted off the base.

Figure 13. The top sheet would be a

removable piece that remains lifted on the tubing due to the pins resting on

the load cells

·

Implementation of additional load cells must consider deflection of the

platform

By testing our

prototypes, we recognized how the platform would deflect significantly in the

center. The beam that connects both sides of the base does provide enough

stability for the base to not fail; however, the deflection cause the platform

to be in conduct with the middle beam. Since this would prevent the load cells

from all the load, an additional load cell was implemented in the middle beam.

This would allow for the load to be distributed through the five load cells

without touching the rectangular base.

Figure 14. This early prototype shows

how the plate deflects in the center

·

Middle beam must have a door to access inside components

To provide

the user with a device that is easily repairable, we are attempting to make all

parts of the device replaceable and easily accessible. Therefore, since the

middle beam will have multiple components inside it, we must incorporate the

use of a door on the side of the beam to allow for easy access to the inside of

the beam.

Figure 15. The team considered

implementing a hinge to have a door for replaceable components such as a

battery

·

Load cell

placement position on rectangular tubing

The team faced

much difficulty about where to place the load cells. The middle of the load

cell holds the strain gauge, which measures the displacement of the center

section as it is pushed down while the outside section remains on a flat

surface. Little to no movement of the entire load cell is necessary to ensure

that the best accuracy is achieved. Therefore, scenarios involving the load

cell inside and outside of the rectangular base were considered and tested.

With the load cells outside and on top of the rectangular base, concerns arose over

how to prevent the outside weather and animals (bees) impact the load cell. With

the load cells inside the rectangular base, it allows them to be protected well.

Figure 16. Both

scenarios with the load cell on top and inside of the base were tested with

multiple prototypes

·

Development of leg extension for platform to be in direct contact with

load cells

The accuracy

of the readings obtained from the load cells depends greatly on the fact that

the load desired to be measured sits directly on the load cell so that none of

its weight can be distributed among other components of the device. Therefore,

the need to develop an extension to the platform so that it touches the load

cells exclusively is imperative. This presents a challenge in the manufacturing

of such extension to the platform due to the dimensions and shape of the load

cells. Certain structural alterations such as an indentation or a tap thread on

top of the load cell must be made in order to secure that the leg extension and

the load cells remain in contact permanently.

Figure 17. Above

shows how the leg, which a screw for this prototype, is resting directly on the

load cell

We found that physical prototyping

was very helpful to increase our understanding of the problem and the

feasibility of our solutions. Our first prototypes were simple but useful and

we continued evolving into more complex ones.

This was our first prototype, it may

be simple, but it helped us understand how the architectural design of our

device must be for it to be able to withstand the load of the beehive. This

first prototype allowed us to get an idea of the dimensions and ratios required

for the parts in our actual product. This early prototype helped us acknowledge

that the structural design of our product is of vital importance since it was

able to withstand a weight of almost 180 lbs. even though the prototype was made

of cardboard and assembled with duct tape.

Figure 18. First prototype

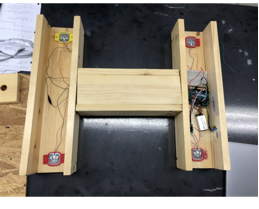

This was our second prototype, which

was made of compressed wood, and in comparison, with our earliest prototype it

was more complex. For this second prototype we used nails to assemble all the

parts together and we used a 1:1 scale compared to our final concept design. This

second prototype enabled us to realize that the platform in our device will

deflect due to the high loads it will be subject to.

Figure 19. Second Prototype with multiple

weights resting on top

Our third prototype was made of the

same material as the second prototype, but more care was taken in cutting and assembling

the scale with different dimensions and ratios. Here, we placed the load cells on

top of the base but below the platform and tested it by adding weight on top of

the platform. However, it was concluded that this setup would not be ideal for

several reasons. Applying weight onto the scale showed us that we needed to

modify the amount of load cells by adding one directly in the center of the

middle beam. Another reason is that the load cells would be placed in a

position in which they would be exposed to interactions with bees and other

external agents that may alter the integrity of the load cells and thus cause

significant alterations to the device. Additionally, it was concluded that the

setup would be difficult to manufacture. The placement of the load cells at the

top of the square tubing would require the use of welding to keep the load

cells in place and the contact area between the welded edge on which the load

cell would rest is relatively small. Therefore, it might not be able to withstand

the load of the platform and beehive.

Figure 20. Multiple views of the

third prototype with and without the top sheet

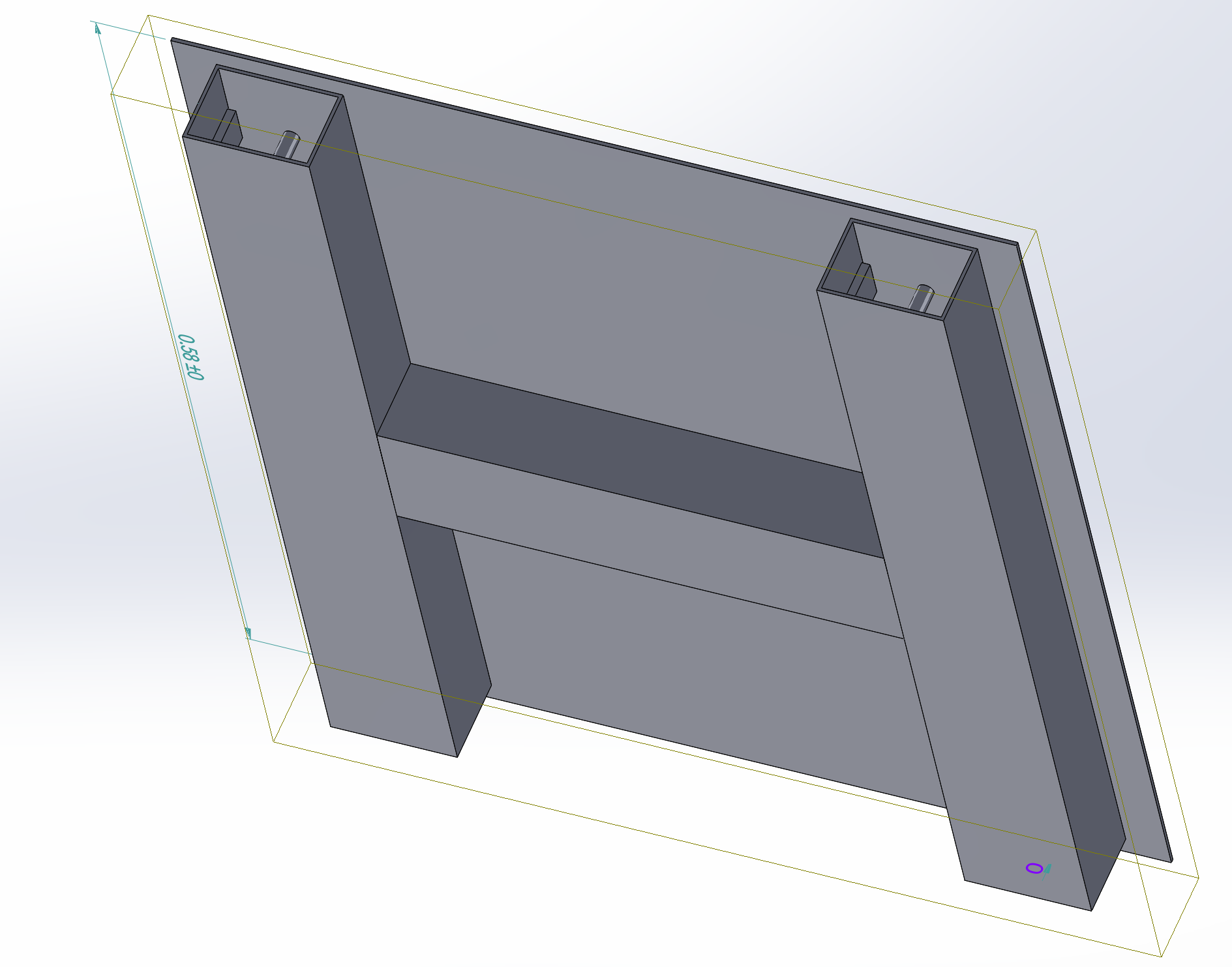

Our fourth prototype is the exact

model we used for the third; however, the difference lies in the placement of

the load cell. We felt securing the load

cells inside the metal tubing was the best option for maintaining safety and maximizing

accuracy of the load cell. Because the platform was no longer going to be in

direct contact with the sensor, a new design had to be created. We decided to

utilize a screw that would be screwed on through the platform and through a

hole on the top surface of the base directly above the load cell. As weight is

applied to the platform, the screw would press down onto a threaded tap located

in the center section of the load cell. This design allows for easy

installation and detachment of the top platform and should evenly distribute

the applied load to all the sensors within the rectangular tubing.

Figure 21. Multiple views of the

fourth prototype with the load cell now inside of the base

The fifth prototype we have developed is a working prototype which features most of the components that will be in use in our final product. This prototype is built of whitewood board is more stable compared to our previous prototypes. This prototype features the use of 4 loadcells, an Arduino board, and an OLED display. Similar to our fourth prototype, the load cells are placed inside the steel tubing. Our working prototype can measure the mass of objects that are placed on top of it and display those masses accurately in the OLED display featured on the side of the device. The accuracy of the mass readings obtained with our working prototype compared to a commercially available weight scale is around 5%. The prototype is very similar to the design of our final product; however, the wood on the base is thicker compared to our steel rectangular tubing. This working prototype provides a core representation of the capabilities of our final product.

Figure 22. Different views of Fifth Prototype

Different view orientations for each

prototype can be found here.

FINAL PRODUCT

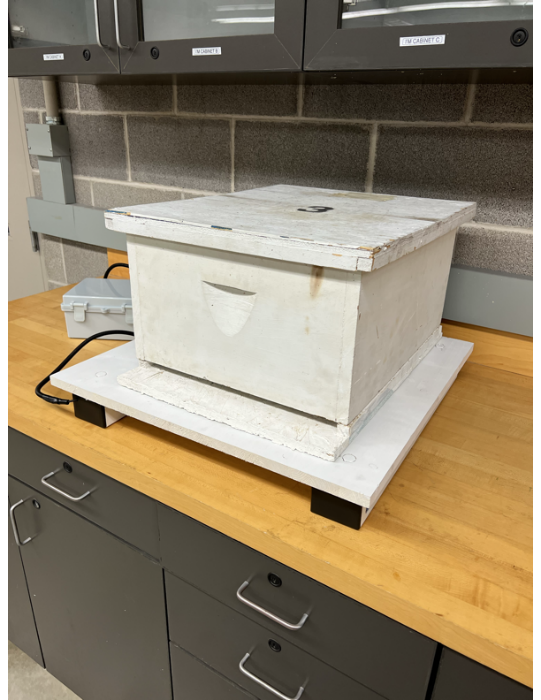

After much

work, this is our final product:

Figure 23. Final Product

The device

is made up of a series of different components that enables the user to mount their

beehives on top of it and read the weight measurements, and more importantly, fluctuations

in the weight readings.

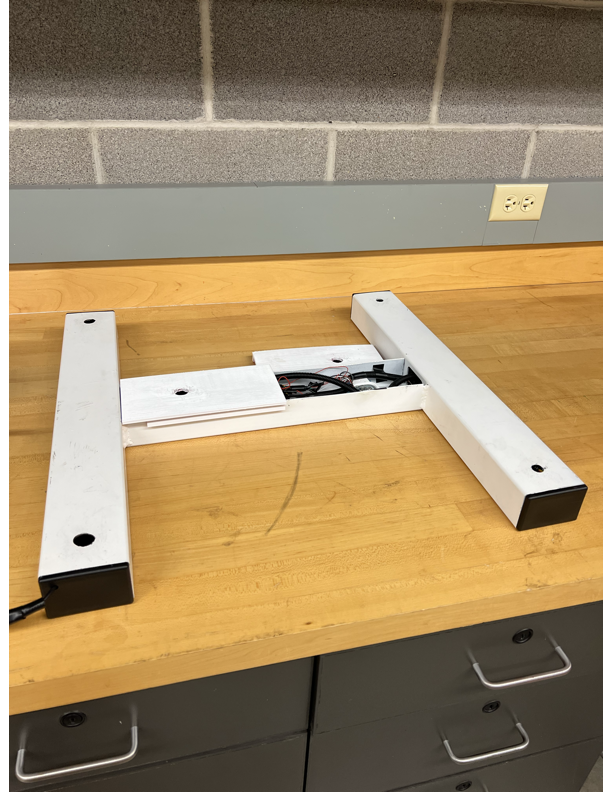

Figure 24. Rectangular Steel Tubing

holding all the electrical components

The base of

the device is a 1010 Steel Rectangular Tubing which encloses the electrical

components of the device. Such components are 6 planar beam loadcells, an

Arduino UNO board, a Bluetooth 4.0 module, and an SD card adapter. The

combination of these components allows the device to work as a whole.

Figure 25. Top wooden sheet being

placed onto the steel tubing

How it works:

Align the proper bolts coming out of the wooden sheet to the six holes on the

rectangular tubing and mount it. With proper alignment, the six bolts should

rest directly on the loadcells. With the wooden sheet mounted, the product is

ready for the beehive setup to be placed on top. When a weight is applied on

top, the bolts will hit the load cell and start generating weight readings. The

OLED display located on the side of the steel frame will display the weight

reading. Similarly, for ease of use, the user is able to monitor the weight of

their beehive setup remotely by through the ArduinoBlue App via Bluetooth.

Our project is a proof of concept

that requires further development, these are some of the pending items:

Development of proprietary app: the

team believes that even though the Arduinoblue app that is currently in use for

the final product is efficient, the development of a proprietary app would be

ideal. Such app is thought to be used for displaying the data obtained by the

loadcells and allowing the user to easily access this information remotely. The

desired mode of remote communication is Bluetooth communication since it is

objectively efficient, and it fits adequately with the specific needs of this

project.

Set-up data storage function: future

additions to the final product the team has developed include a function that

allows for the data gathered in every single reading of the loadcells to be

compiled in a single file. There are two ways in which the team believes this

could be accomplished; the development of a proprietary app or the

implementation of code that allows for the use of SD card. Ideally, within the

mobile app that would be developed to access real time data, the user would

also have the option of looking at graphs that have all the data gathered

throughout a specific amount of time. As a second option, the development of

code built into the device with the use of SD cards as a storage unit would

allow the user to retrieve such card to look at the history of the data

generated by the device.

Development of PCB Board: the team

believes that a factor that could greatly contribute to the efficiency of the

product is the development of a Printed Circuit Board. Such implementation

would allow for cost-efficiency in the project since that could replace many

components that drive the cost of fabricating the device up. In addition, the development

of the PCB board allows for more independence in the use of a proprietary app

as well as the coding language used to program the device.

IN CONCLUSION

Our Senior

Design experience was enlightening in many senses. We were exposed to a new

application of engineering in the world. In particular, we were introduced to

the involvement of engineering in disciplines of agriculture and apiculture. Further,

we had the opportunity to work in an environment that is very similar to an

actual engineering worksite. This has served as great training for us as we

prepare to start our journey into the work force. Introspectively, it made us realize

that as engineers we are bound to work in highly multidisciplinary setups where

we are required to have interactions with an array of people that come from

very different professional and technical backgrounds. As a whole, we believe

that our experience in Senior Design was tough and required a lot of hard work.

However, it provided us with a set of skills and tools that we are going to

benefit from in the professional world. Overall, the experience we have gained

these last two semesters of our Undergraduate Career was worth the long days of

hard work.

REFERENCES

Pahl,

G., and Beitz, W., 1996, Engineering design: A systematic approach, London:

Springer.

"What makes honeybees aggressive?,” last

modified 2010, accessed January 2021, https://www.honeybeesuite.com/what-makes-honey-bees-aggressive/

"Why is weighing your beehive important?,”

last modified 2021, accessed February 2021. https://www.perfectbee.com/blog/weighing-your-beehive-why-and-how#:~:text=Weighing%20your%20hive%20should%20give,how%20many%20bees)%20are%20inside.&text=Weighing%20is%20useful%20during%20other,be%20surprised%20at%20their%20speed

"The Honey Industry,” last modified 2021,

accessed February 2021. https://www.peta.org/issues/animals-used-for-food/animals-used-food-factsheets/honey-factory-farmed-bees/

"Strain Gauge Load Cell Basics,” accessed

February 2021, https://www.800loadcel.com/load-cell-and-strain-gauge-basics.html

"SolutionBee HM-6 Hive Monitor with WiFi”,

accessed February 2021, https://www.perfectbee.com/store/accessories-and-tools/monitors-and-scales/solutionbee-hm-6-hive-monitor

"Showcasing Student Innovation,” last

modified April 2018, accessed February 2021, https://forums.ni.com/t5/Showcasing-Student-Innovation/Weight-my-Bees-Measuring-Beehive-Weight-to-Monitor-Colony-Health/ta-p/3787134?profile.language=en

We went through a meticulous design process to arrive to the

final solution. The information on this page is a summary intended for the

general public. To learn about the project details, visit the DESIGN PROCESS

page. To obtain access contact the course instructor or click here.

The team

received help from various people, their help was critical to our success, we

would like to acknowledge Dr. Noe Vargas Hernandez, Dr. Joanne Rampersad-Ammons,

Mr. Greg Potter, Dr. Horacio Vasquez, and Reyes Mendoza.