UTRGV / COLLEGE OF ENGINEERING AND COMPUTER

SCIENCE / MECHANICAL ENGINEERING DEPARTMENT

TEAM 3: Mesquite

Bean Harvester

|

Students

(L-R) |

· Carlos

Guzman · Victoria

Garza · Stephanie

Ramos · Alexandra

Salinas |

|

Faculty Advisor(s) |

· Dr.

Arturo Fuentes · Dr.

Joanne Rampersad-Ammons · Mr.

John Pemelton |

INDEX

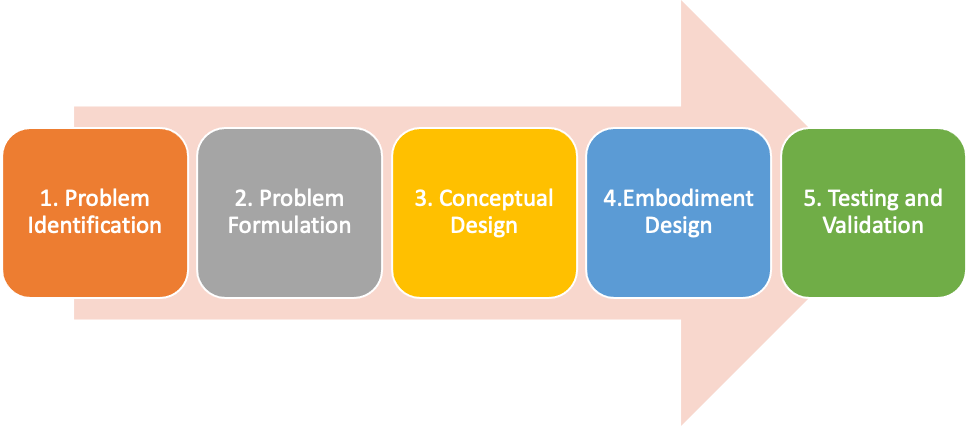

For

our Senior Design process, we made an effort to address and consider every

detail to determine our final concept and product design. Our design process

consists of five sub-processes, which are used to guide us to a final product.

Figure 1:

Design Process

·

1. Problem Identification

Clearly

identifying a problem is imperative for the design process because it is the root

of the project. Determining the central issue of a certain subject can allow

one to focus on that problem without deviating from it and allow one to develop

a problem statement. [4]

· 2. Problem Formulation

Clearly

defining the problem is essential to the design process. This consists of finding

and learning about the major and minor details of the problem subject to make

well-educated decisions regarding the central issue. The methods of problem

formulation include background research, research on competitive products, user

research, and design specifications. [3]

· 3. Conceptual Design

A

crucial aspect of the design process is to determine the functions of the

product that are sought to solve the problem that is identified. Within these

functions, solutions can be presented specifically to those functions and cohesively

brought together into concept variants. From here, a final design can be

determined based on qualitative or quantitative eliminations.

· 4. Embodiment Design

The

embodiment process brings the final concept to life and requires using engineering

aspects to tackle technical questions. The design specifications of the product

itself are considered, and the final design is realized.

· 5. Testing and Validation

In

this final sub-process, the final design is tested, evaluated, and optimized so

that it can be used to effectively solve the problem identified. After testing

and validation, the final product can be directly led to a higher level of production.

Clearly

identifying a problem is crucial for the design process because it is the root

of the project. We, as a team, have decided to make an impact within our local

community by tackling a problem introduced by mesquite farmers within Linn,

Texas.

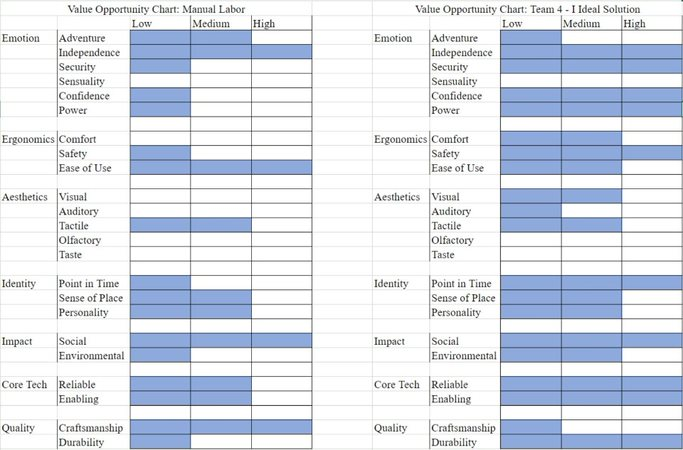

Product Opportunity

Gap

Given

the growing trend for healthier foods and products, there is a greater demand

for mesquite beans. Because the main harvesting method of the mesquite industry

is manual labor, which is very strenuous and time-consuming with minor

results, there is a demand for a new and more efficient way for harvesting

mesquite beans.

Value Opportunity

Chart (VOA)

For

our Product Opportunity Gap, we developed a Value Opportunity Chart (VOA),

which directly compares Manual Labor to our prospective product. The purpose of

these two graphs is to compare the ideal solution to that of the current

workflow of the Cappadona Ranch.

Table 1: Value Opportunity Chart

Figure 2:

Describing Our Value Opportunity Chart

Although

our product would have these clear advantages over manual labor, our product

would have a couple of drawbacks.

-

The first

drawback of our product would be that it would need proper training for

operation. However, this is specific towards the safety of the user.

-

The

second drawback would be that our product may not be as effective as manual

labor in their ability to access to hard-to-reach areas.

-

Despite

the drawbacks of the product, with safety being an upmost priority, the pros

certainly outweigh the cons of manual labor, especially considering the safety hazards

that the current field workers must go through every year during harvest

season.

FINAL PROBLEM STATEMENT

Click the icon above to hear our

Final Problem Statement!

Clearly defining the problem is

essential to the design process. The methods of problem formulation include

background research, research on competitive products, user research, and design

specifications.

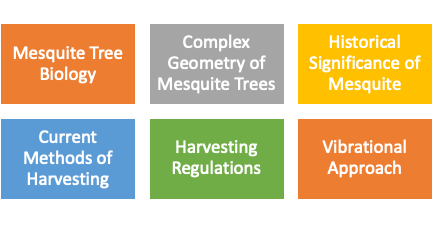

BACKGROUND

RESEARCH

To better

understand the context of the problem to solve, we conducted Background

Research on the following topics:

All the sub-categories above are

incredibly important when setting up the foundational work of the design

process. With all of these in mind, we can use the knowledge gained towards

conceptual design work.

To view our Background Research folder,

view here.

COMPETITIVE

PRODUCTS

To avoid

“reinventing the wheel,” we looked at existing solutions and competitive

products:

Much of the references that were

looked at for competitive products were that in use for agriculture. For

example, the hook as shown above is a Kadıoğlu Emr400 Branch Shaker Harvesting Machine. This

mechanical hook is used for vibrational applications to branches and is one of

the many competing products that were found during our research.

To view our Competitive Products

folder, view here.

USER RESEARCH

Understanding

the user wants and needs is key for the design of a valuable product, we applied

a variety of User Research techniques for that purpose:

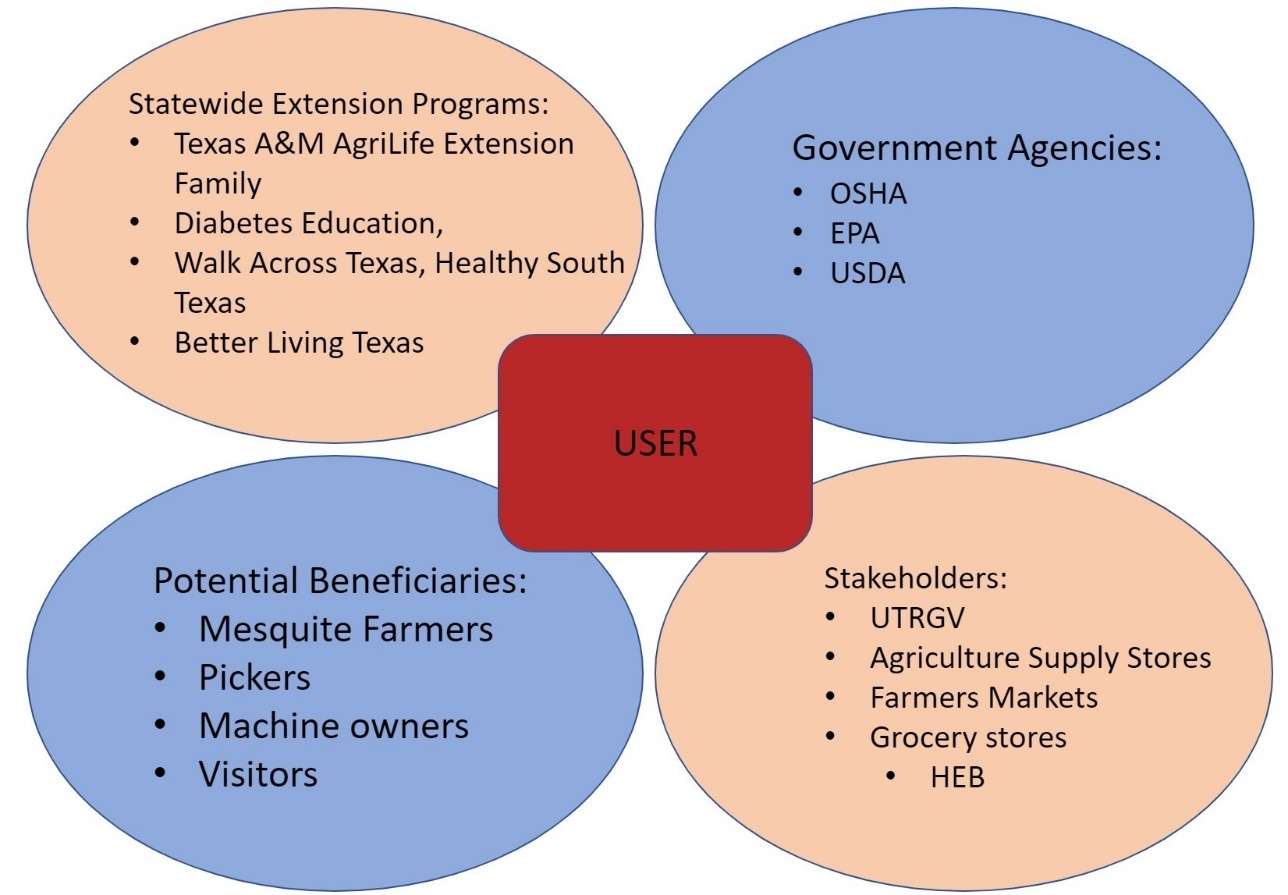

Technique #1: Stakeholder Map

Figure 3:

Stakeholder Map

Our

stakeholder map shows us the people and businesses that will be directly

affected by the decisions made for our designs. To assist with understanding

the user and the pains and gains of the business, we have conducted a personal

interview between the team and the Cappadona family, which can be heard below.

Technique #2: Scenario Development

Click on the icon above to view our

Scenario Development!

To view our Scenario Development

document, view here.

Technique #3: Interview with the Cappadona’s

Click the icon above to hear the audio file

from our interview with the Cappadonas!

To view our notes from our Interview

with the Cappadonas, view here.

DESIGN SPECIFICATION

The Design

Specification captures the “essence” of the design by showcasing the demands

and wants of our users. The following table shows the Design Specifications for

our project:

Table 2: Design Specification Table

|

Date

Changed |

Demand/Want |

Requirement

List for the Mesquite Bean Picker |

Responsibility |

|

2/18/2020 2/18/2020 5/1/2020 3/3/2020 3/3/2020 |

W D D D D |

Geometry Maximum Radius

-- 24 ft. Average Canopy

Radius – 15 ft. Telescoping Arm Extender - 6

ft - 12 ft. Localized

Collection (1/4th of Canopy Area) Vibration

Interface – Meets Branch Perimeter |

|

|

3/3/2020 3/3/2020 3/3/2020 3/3/2020 3/3/2020 3/3/2020 |

D W W W D W |

Energy Localized Vibration Battery –

24 Volt Battery (Car Battery) Gasoline/Motor Rotational Gravitational

Freefall Electric (for

Vibration) |

|

|

3/3/2020 3/3/2020 3/3/2020 3/3/2020 3/3/2020 |

D D D W W |

Material Heavy Duty Material for

Tarpaulin Aluminum Arm Extender Steel Branch

Interface Aluminum Frame

(Tarpaulin) Aluminum Hopper |

|

|

3/3/2020 3/3/2020 |

D D W W |

Signals Dial for

Vibration Control LED Light LED

Display Sound for

I/O of Vibration Interface |

|

|

3/3/2020 3/3/2020 |

W D D |

Safety No sharp

blades Remove the user

from physically touching the tree due to thorns Remove the need

for standing on elevated height |

|

|

3/3/2020 3/3/2020 3/3/2020 3/3/2020 3/3/2020 3/3/2020 |

D W W D W W |

Ergonomics Low profile to

account for small canopy height <

50-75 lb. to

Maneuver the collection device Can be easily

pushed by physical effort <

125 lb. for Easy Movement Ease of Use Handheld

Vibration Machine |

|

|

|

W |

Costs < $400 for

the whole project |

|

To view more details about our Design

Specifications, view here.

Figure 4:

Our Goal and Proposed Solution on a single PowerPoint slide

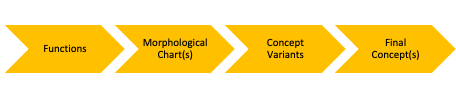

A crucial aspect of the design process is to determine the

functions of the product that are sought to solve the problem that is

identified. Within these functions, solutions can be presented specifically to

those functions and cohesively brought together into concept variants. From

here, a final design can be determined based on qualitative or quantitative

eliminations.

FUNCTIONAL DESIGN

Creating a

Functional Diagram allows us to understand what the product needs to do but not

necessarily how.

Figure 5: Functional Diagram

Although our Functional Diagram shows

only one function, we decided to divide our project into two parts. One

function for Picking Mesquite Beans and the other for Collecting Mesquite

Beans. Each of these functions contain sub-functions within themselves.

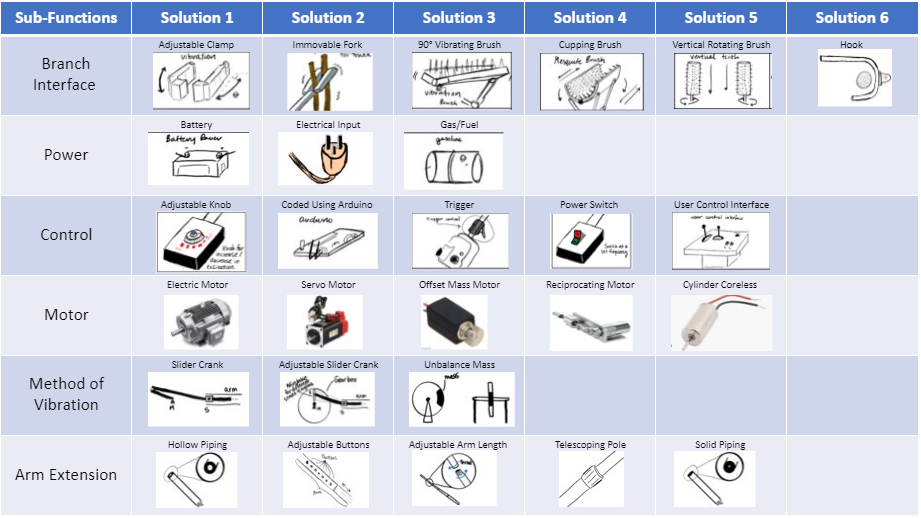

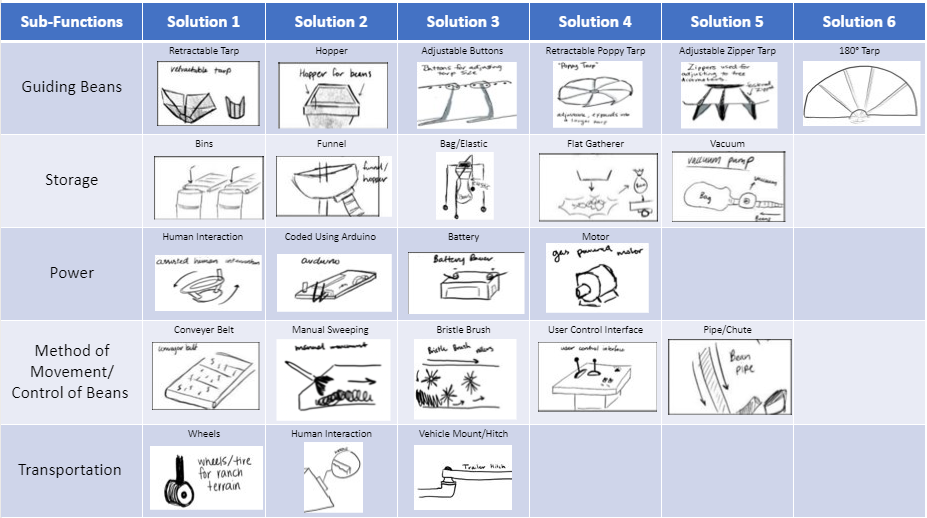

MORPHOLOGICAL

CHARTS AND SUB-FUNCTION CHARTS

The

Morphological Chart helps us explore the universe of viable solutions for each

function’s sub-function in an orderly fashion. The Sub-Function Chart helps us

to decide on the best solution for the specific sub-function based on certain criteria.

Function #1: EXCITATION

Table 3: Excitation Morphological Chart

The Excitation function is broken down

into six functions: Branch Interface, Power, Control, Motor, Method of

Vibration, and Arm Extension.

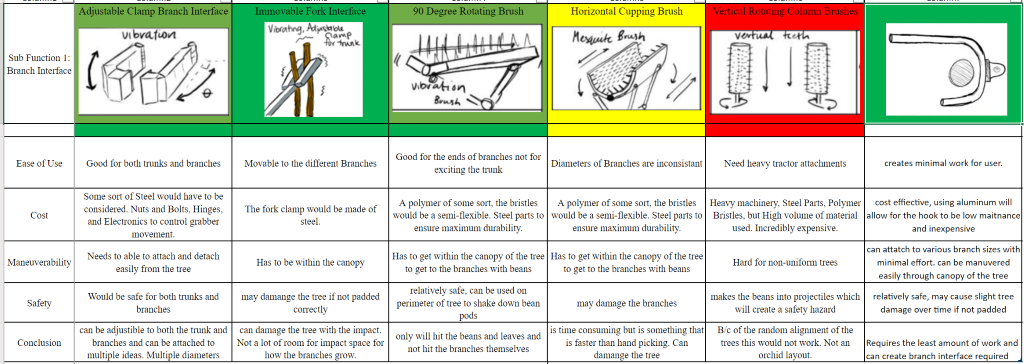

Table 4: Excitation Subfunction Chart - Branch Interface

The Branch Interface requires connection between

the machine and the branch to allow for constant vibration. This

subfunction is comparing all its solutions to the following criteria: Ease of

Use, Cost, Mobility, and Safety.

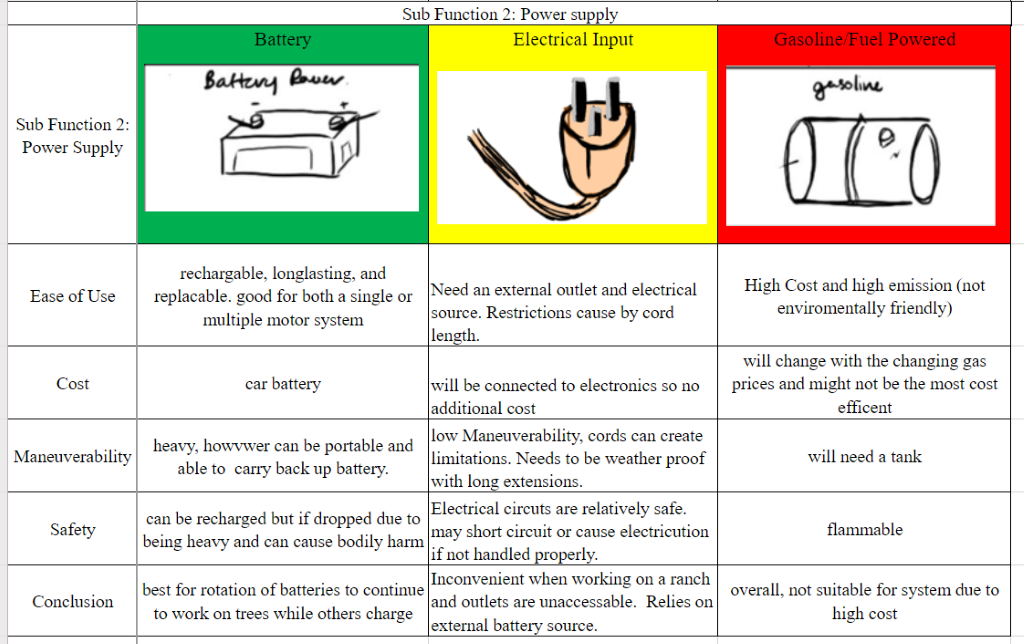

Table 5: Excitation Subfunction Chart - Power Supply

The second subfunction is the Power

Supply. Its solutions will be compared using the following criteria: Ease of

Use, Cost, Maneuverability, and Safety.

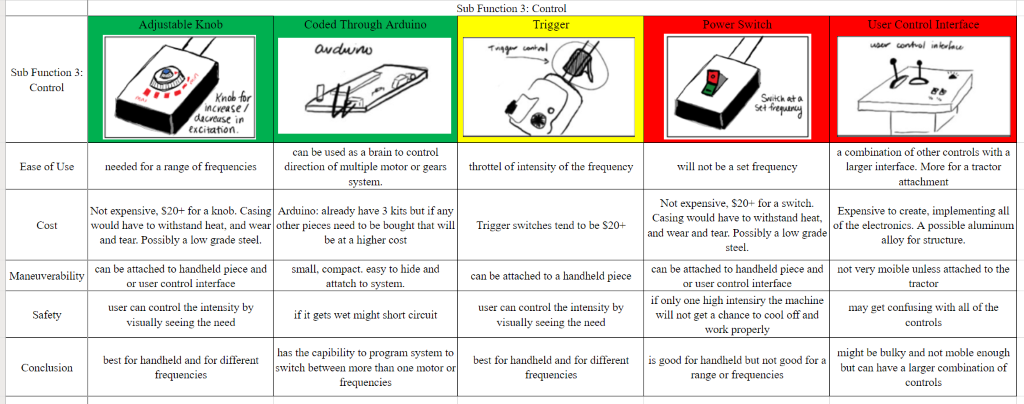

Table 6: Excitation Subfunction Chart - Control

Control is essential for both holding

the vibration frequency and for connecting the machine together. Its solutions

will be compared using the following criteria: Ease of Use, Cost,

Maneuverability, and Safety.

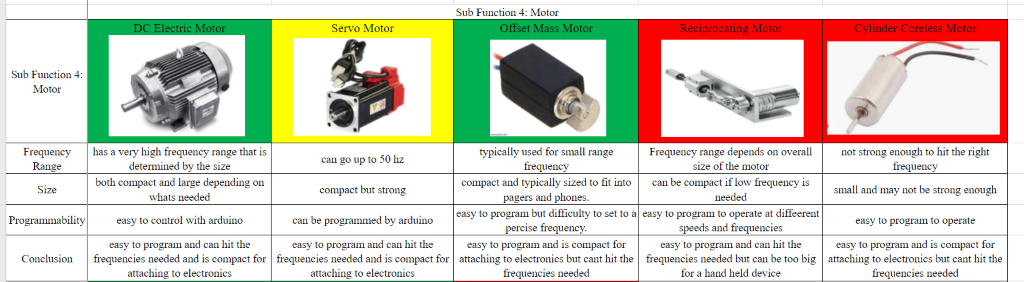

Table 7: Excitation Subfunction Chart - Motor

The fourth subfunction is the Motor.

Its solutions will be compared using the following criteria: Frequency Range,

Size, and Programmability.

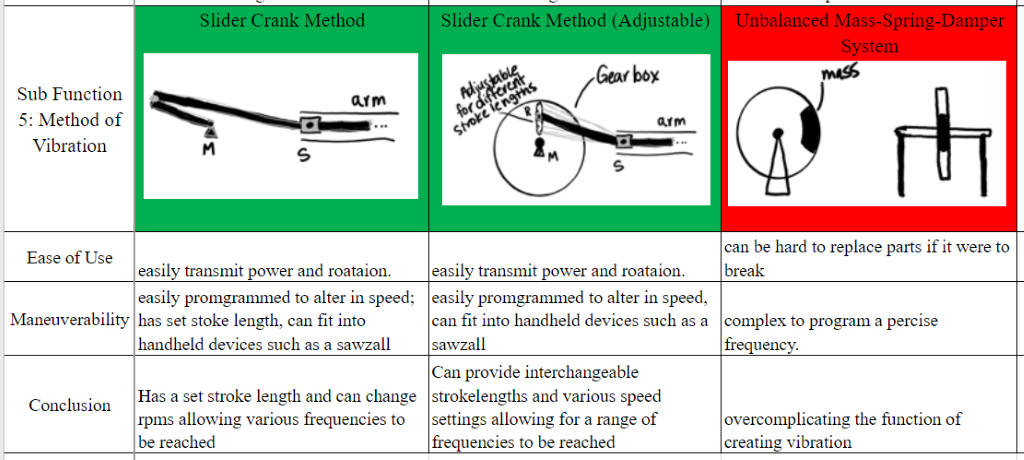

Table 8: Excitation Subfunction Chart - Method of Vibration

Method of Vibration is important

because different mechanisms have different variables that are considered. The

method that is applied will also affect the target vibration modes. Its

solutions will be compared using the following criteria: Ease of Use and

Maneuverability.

Table 9: Excitation Subfunction Chart - Arm Extension

Arm Extension allows the machine to

reach into the higher points of the tree. Its solutions are evaluated with the

following criteria: Weight, Cost, Maneuverability, and Safety

Function #2: COLLECTION

Table 10: Collection Morphological Chart

The Collection function is broken down

into five sub-functions: Guiding Beans, Storage, Power, Method of Movement/Control

of Beans, and Transportation.

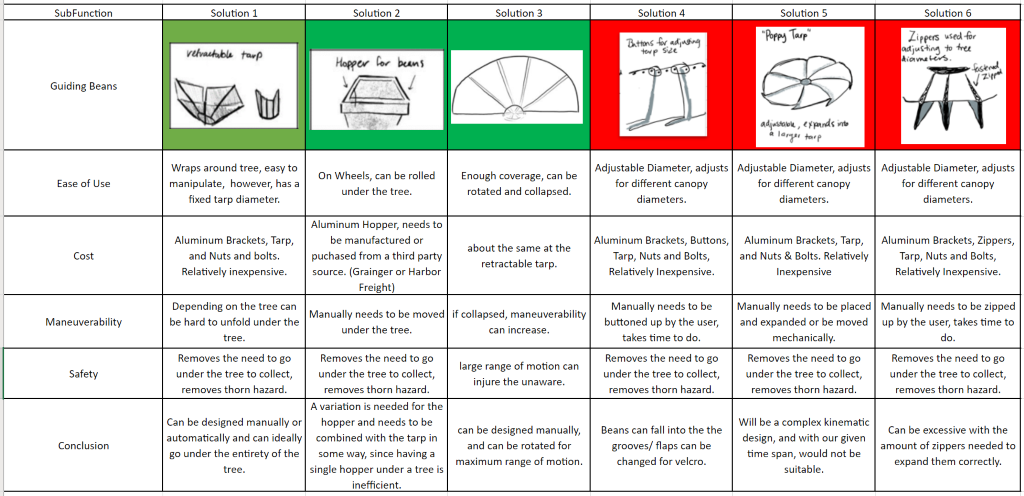

Table 11: Collection Subfunction Chart - Guiding Beans

Guiding the beans requires that there be

a location for beans to fall and allows for the guidance of the beans to the

next step of the process. Its solutions will be evaluated through the following

criteria: Ease of Use, Cost, Maneuverability, and Safety.

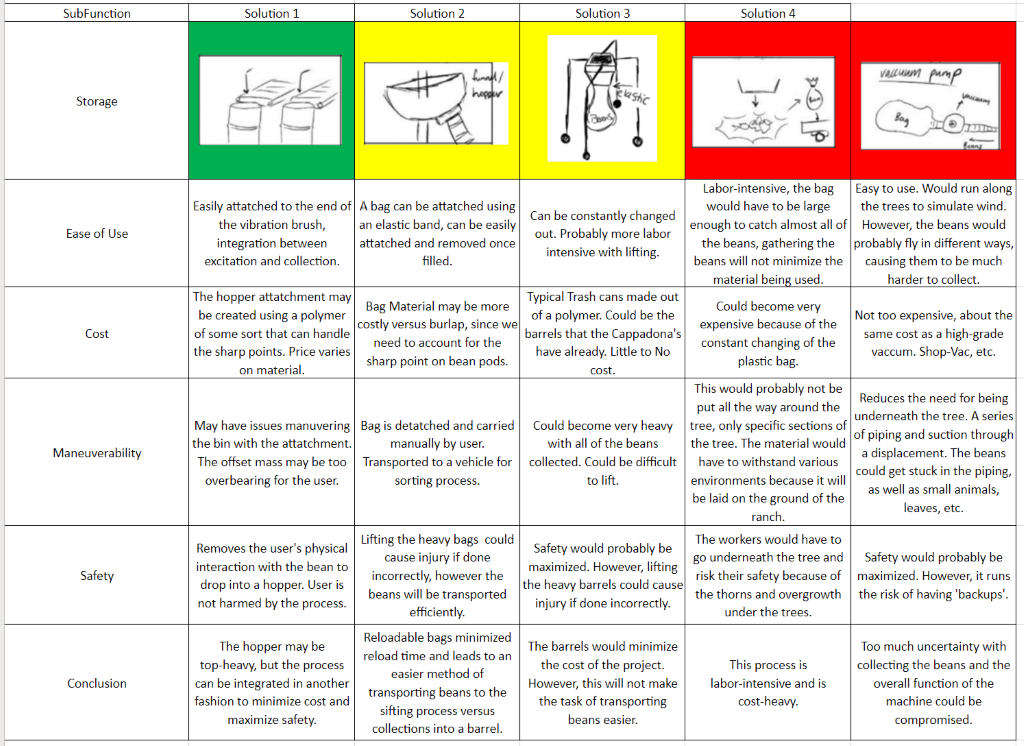

Table 12: Collection Subfunction Chart - Storage

Storage of the beans is the last

step of the system. With the guidance of the bean to the storage selection, the

beans reach their destination where the user can use the beans for the next

step of their manufacturing process. Its solutions are evaluated with the

following criteria: Ease of Use, Cost, Maneuverability, and Safety.

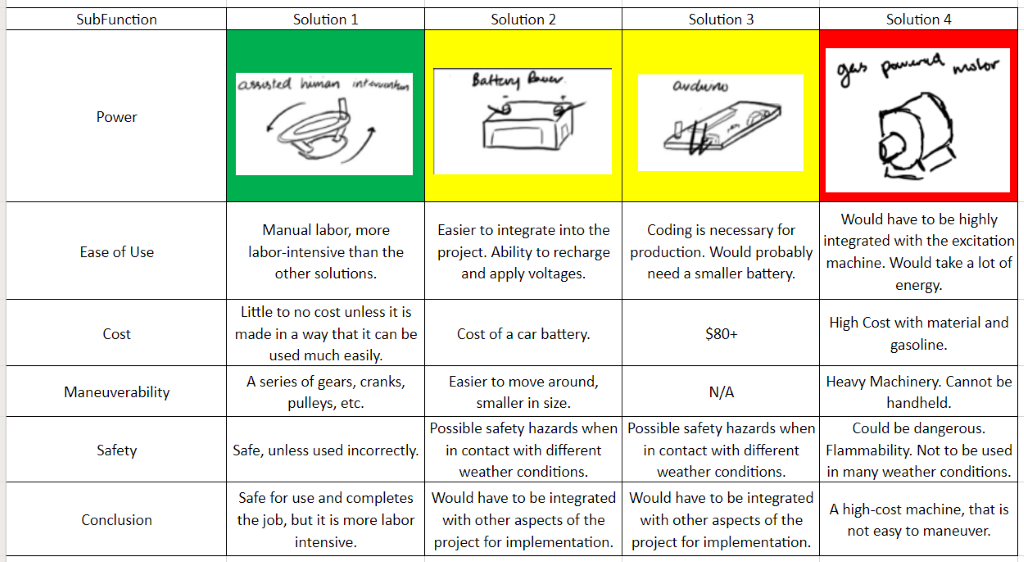

Table 13: Collection Subfunction Chart - Power

The third subfunction is Power. Its

solutions are evaluated with the following criteria: Ease of Use, Cost,

Maneuverability, and Safety.

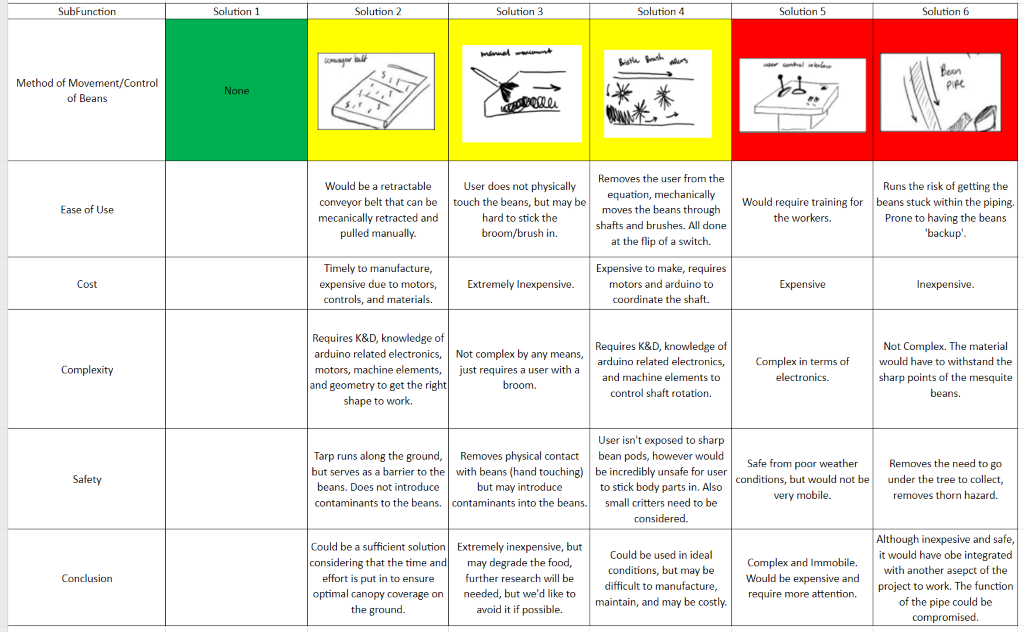

Table 14: Collection Subfunction Chart - Method of Movement/Control of Beans

The fourth subfunction is Method of

Movement/Control of Beans. Its solutions are evaluated with the following

criteria: Ease of Use, Cost, Complexity, and Safety.

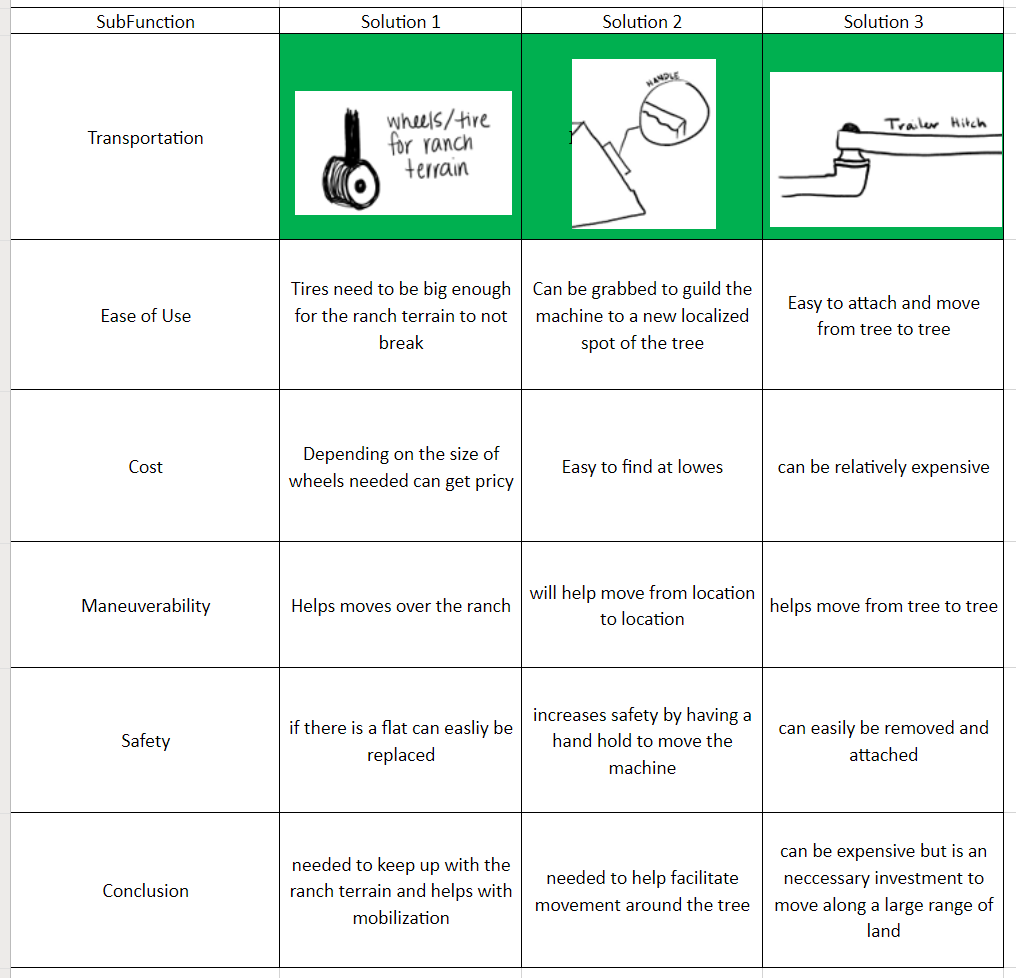

Table 15: Collection Subfunction Chart - Transportation

The fifth subfunction is

Transportation. Its solutions are evaluated with the following criteria: Ease

of Use, Cost, Maneuverability, and Safety.

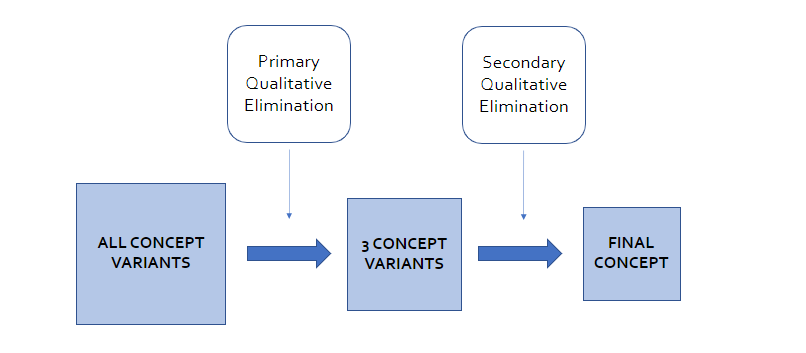

CONCEPT VARIANTS

AND SELECTION PROCESS

Combining

all practical solutions would generate a factorial number of concept variants,

we had to be selective to find the best ones. This is our Concept Variant

Elimination Process:

Figure 6:

Concept Variant Elimination Process

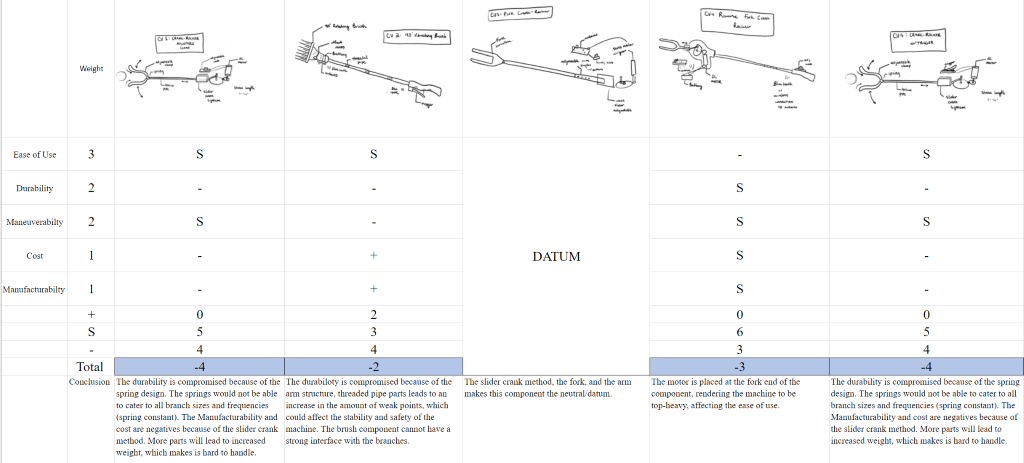

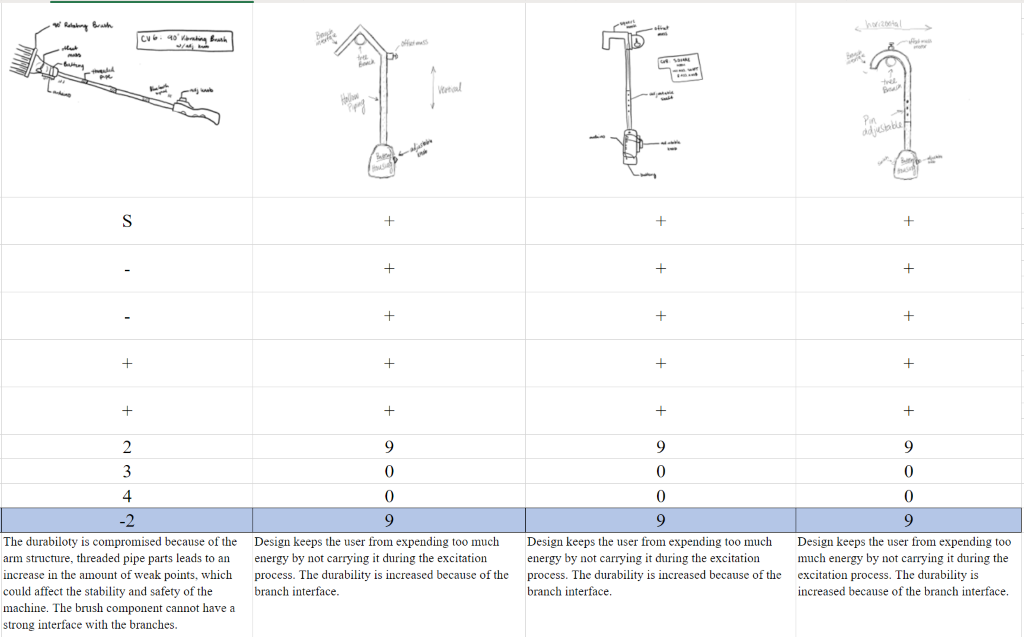

Function 1: EXCITATION

To begin our selection process, we set

up a datum to compare our concept variants against each other. The concept

variants are evaluated by the following criteria: Ease of Use (3 points), Durability

(2 points), Maneuverability (2 points), Cost (1 point), and Manufacturability

(1 point).

The three concept variants with the

highest scores will survive the Primary Qualitative Elimination and move

towards the Secondary Qualitative Elimination process.

Table 16: Primary Qualitative Elimination for Excitation

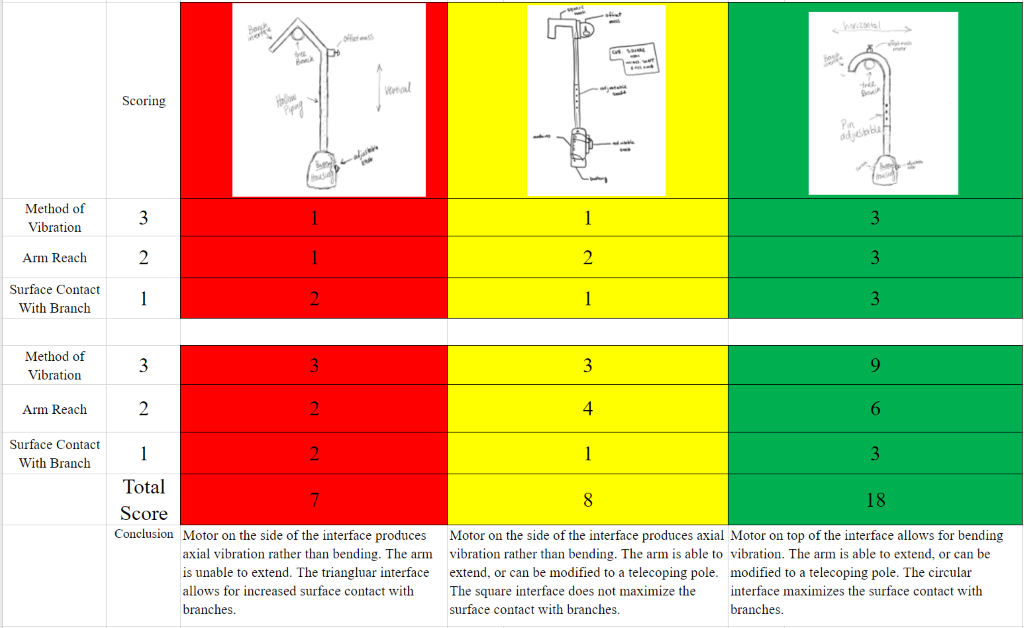

The top three concept variants are put

through a secondary qualitative elimination process and evaluated by the

following criteria: Method of Vibration (3 points), Arm Reach (2 points), and

Surface Contact with Branch (1 point).

Table 17: Secondary Qualitative Elimination for Excitation

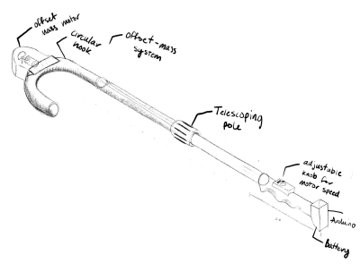

The highest scoring concept variant is

the circular, extending hook. This concept variant maximizes surface contact

with the branch, maximizes arm reach, and will produce the bending vibration of

the mesquite beans.

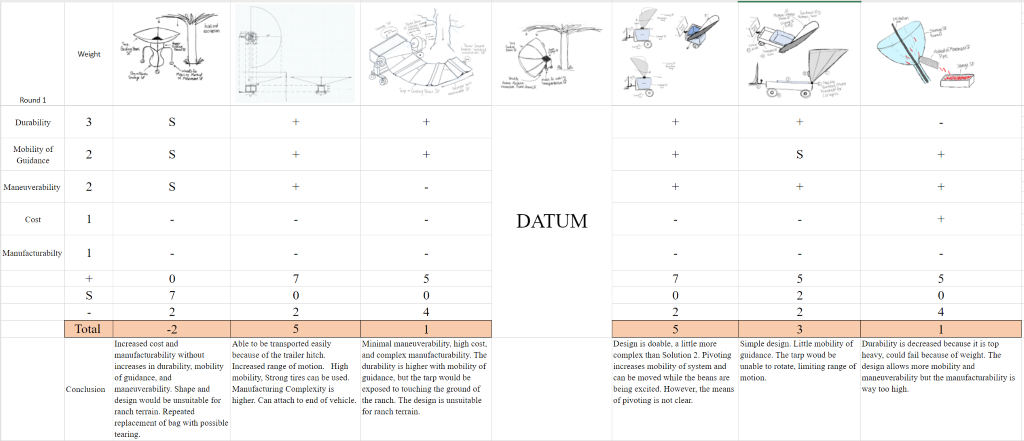

COLLECTION

To begin our selection process, we set

up a datum to compare our concept variants against each other. The concept

variants are evaluated by the following criteria: Durability (3 points),

Mobility of Guidance (2 points), Maneuverability (2 points), Cost (1 point),

and Manufacturability (1 point).

The three concept variants with the

highest scores will survive the Primary Qualitative Elimination and move

towards the Secondary Qualitative Elimination process.

Table 18: Primary Qualitative Elimination for Collection

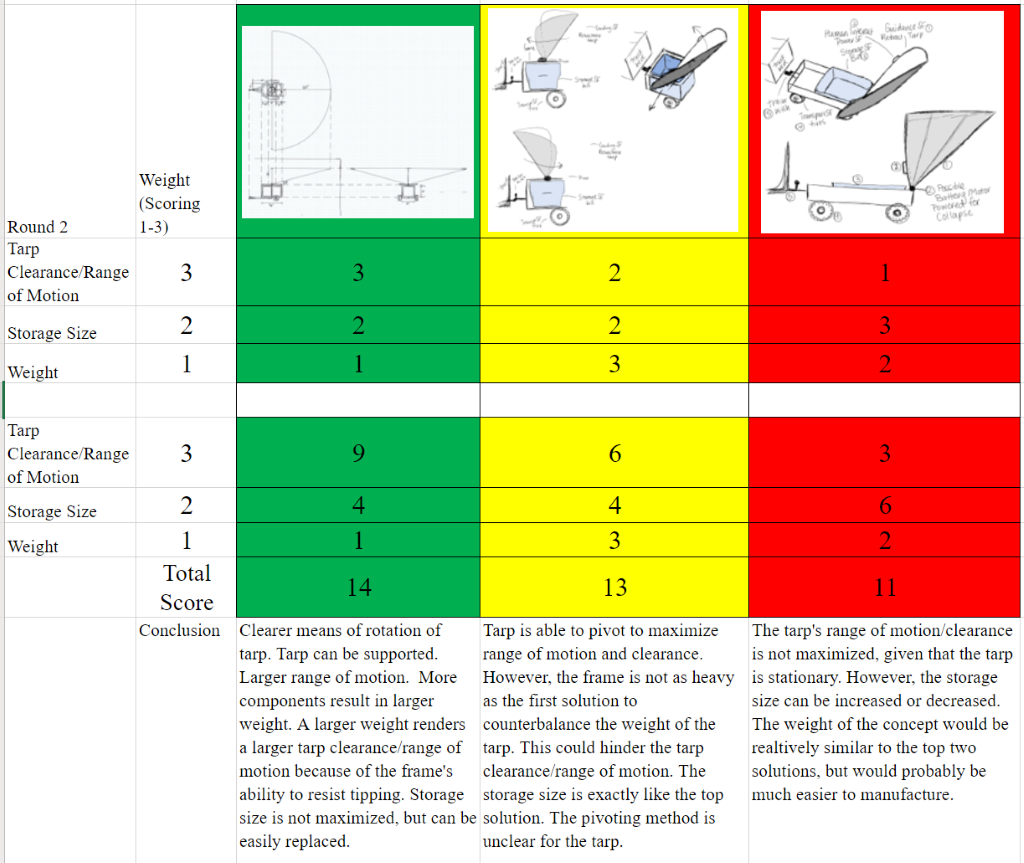

The top three concept variants are put

through a secondary qualitative elimination process and evaluated by the

following criteria: Tarp Clearance/Range of Motion (3 points), Storage Size (2

points), and Weight (1 point).

Table 19: Secondary Qualitative Elimination for Collection

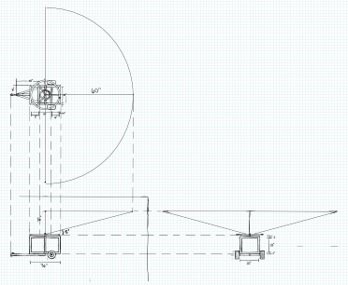

The highest scoring concept variant is

the Pivoting, Adjustable Height 180 Tarp. This concept variant maximizes tarp

clearance/range of motion, maximizes storage size, and will be heavy enough to

avoid tipping with the weight of the tarp.

FINAL CONCEPT(S)

After the

selection process we arrived at the Final Concepts for both Excitation and

Collection.

Figure 7: Circular Hook with Telescoping Pole – EXCITATION

Figure 8: Circular Hook with Telescoping Pole on Tree

Figure 9: Pivoting 180 Degree, Adjustable Height – COLLECTION

The

embodiment process brings the final concept to life and requires using

engineering aspects to tackle technical questions. The design specifications of

the product itself are considered, and the final design is realized.

STRATEGIES AND

PRIORITIES

Starting

from our final concept, we identified the necessary analyses and engineering

work to realize the concept into a product.

TASK 1: DETERMINE

THE TYPE OF VIBRATION TO DROP THE MESQUITE BEANS

Before building, we needed to

determine the most optimal form of vibration to get the beans to fall. The

different forms of vibration, along with their respective stress

concentrations, are:

Figure 10: Forms of Vibration

The primary vibrational concepts used

for this project are Natural Frequency Resonance, and Mode Shapes.

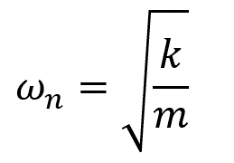

· Natural Frequency: The frequency in which a system vibrates at after an initial

disturbance without external forces. [2] The natural frequency of a system can

be denoted as:

Equation 1:

General Natural Frequency Equation

where k is

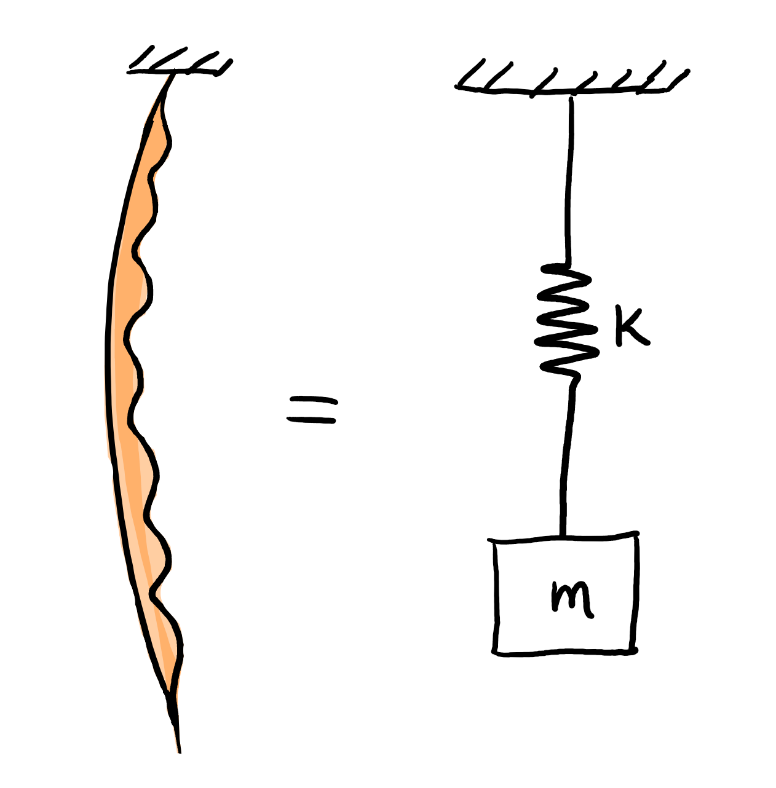

the system’s stiffness and m is the system’s mass. The mesquite bean can be

modeled as a single degree of freedom mass-spring system, shown in Figure 11.

With SDOF systems, there is only one natural frequency within the system.

Figure 11: Mesquite Bean Modeled as a SDOF Mass-Spring System

· Resonance: When

the driving frequency of the system reaches/equals the system’s natural

frequency, resonance occurs. During resonance, the system is prone to breakage

or failure. Resonance can be denoted as:

![]()

Equation 2:

Evidence of Resonance

Where ωn is the natural frequency of the system. [2] The goal of the

vibrational aspect is to find the natural frequency of the mesquite bean to

match the driving frequency. From here, we should be able to reach resonance

and cause the mesquite bean to break off the branch.

· Mode shape: The shape that a system takes when

it is excited. For this project’s analyses, the mode shape number is denoted as

ⴖ.

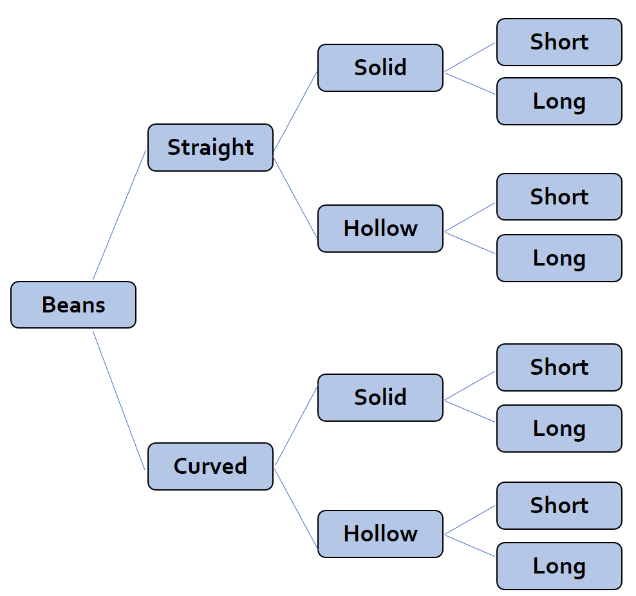

For this analysis, we decided to use

Frequency Studies through the Finite Element Analysis method for multiple

Computer Aided Design (CAD) models. Through this study, we would be able to

determine the natural frequencies of the mesquite beans.

To view our Mesquite Bean Sample

Measurements, view here.

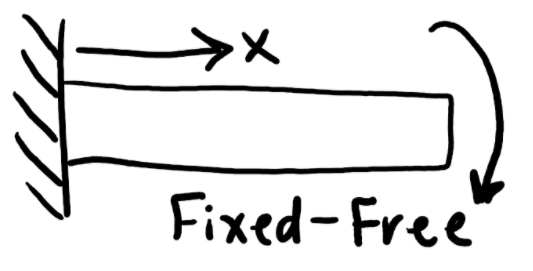

For the primary testing, we used

simple cylinders with dimensions similar to that of our mesquite bean sample

measurements. We completed the studies by treating our mesquite beans as clamped-free

cantilever beams. We used the following figures and equations for reference to

complete sanity checks for each type of

vibration and their first mode shape [2]:

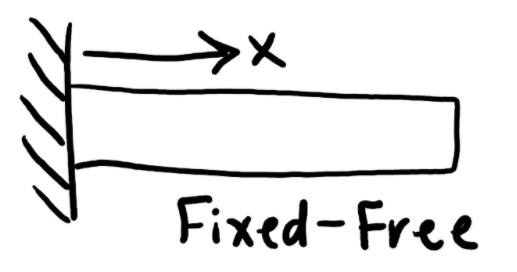

·

AXIAL VIBRATION

Figure 12: Axial Deformation Due to Axial Vibration

Equation 3: Natural Frequency Equation for Axial Vibration for the nth Mode Shape

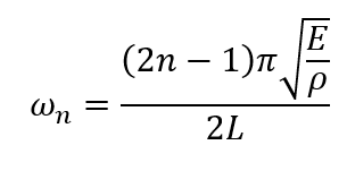

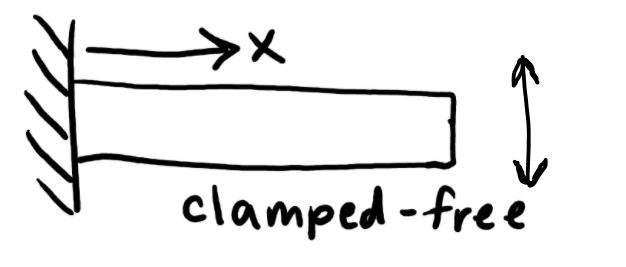

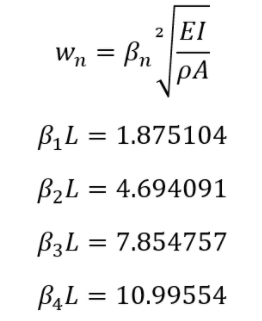

· BENDING VIBRATION

Figure 13: Perpendicular-To-X Deformation Due to Bending Vibration

Equation 4: Natural Frequency Equation for Bending Vibration for the nth Mode Shape

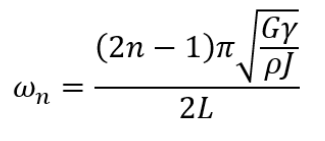

· TORSIONAL VIBRATION

Figure 14: Deformation Due to Torsional Vibration

Equation 5: Natural Frequency Equation for Torsional Vibration for the nth Mode Shape

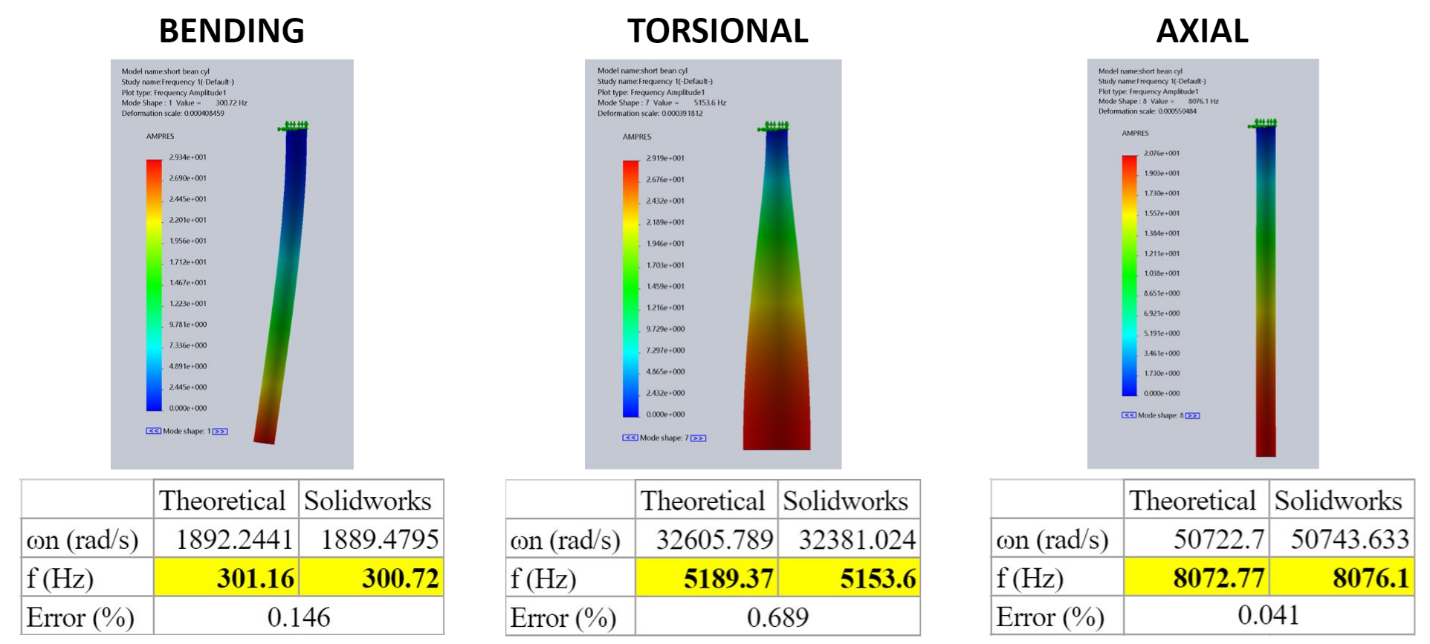

Figure 15: Sanity Checks for the Different Forms of Vibration

Our sanity

checks checked out with errors less than 1%. From here, we moved to increase

the complexity of our mesquite beans, as shown in Figures 16 and 17. We

completed the same FEA (Finite Element Analysis) process for the complex beans.

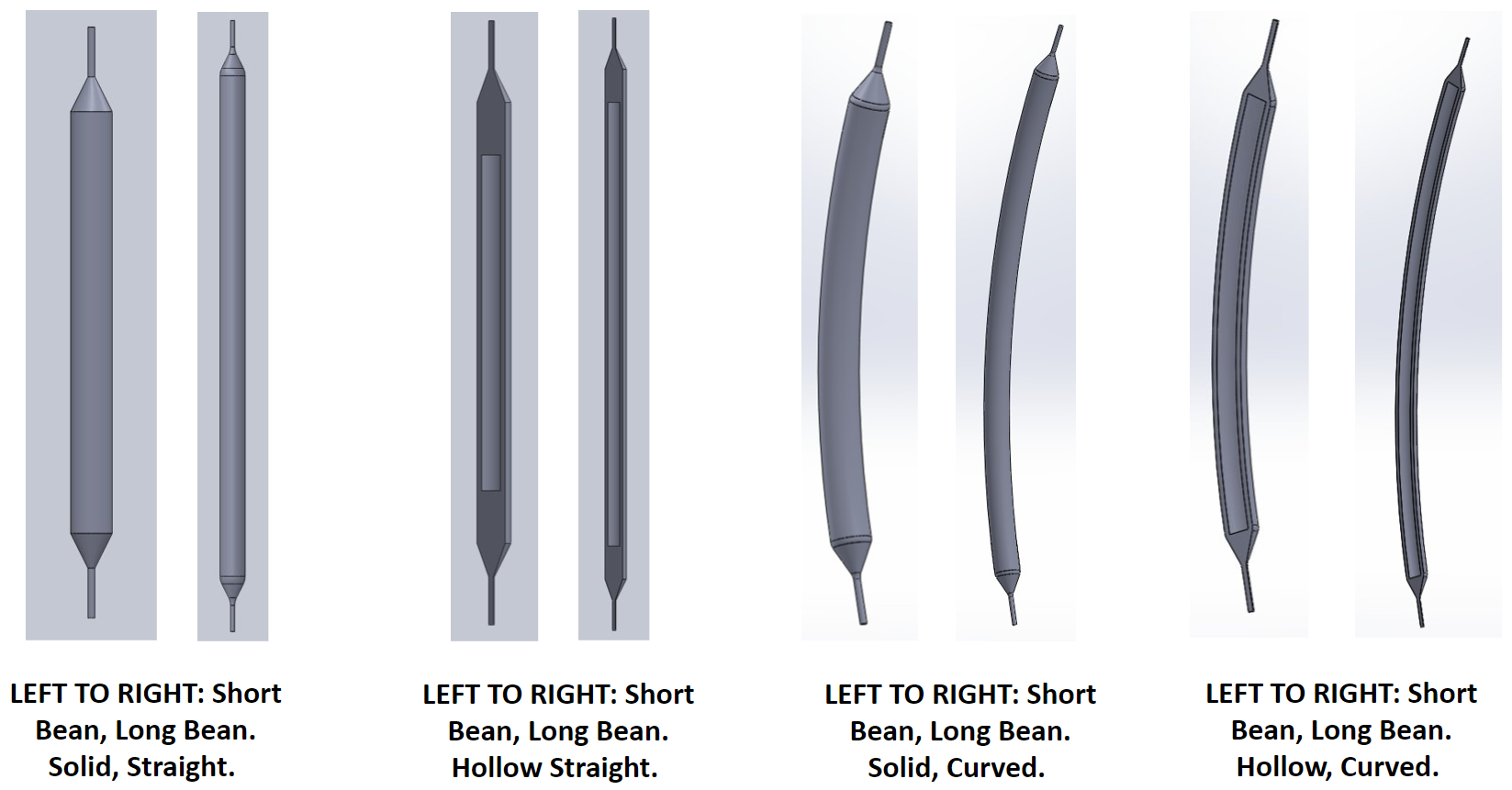

Figure 16: Different CAD Models Created

Figure 17: Increasing the Complexity of Mesquite Bean CAD Models

To view all

our Mesquite Bean CAD Models, view here.

To view the FEA Simulations on our

Mesquite Bean CAD Models, view here.

To view the Sanity Checks for the FEA

Simulations, view here.

By completing a comparative analysis

between our theoretical and experimental values, we determined the following:

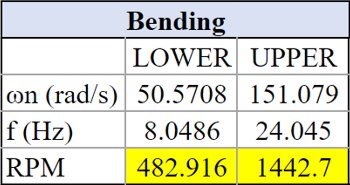

· Bending Vibration is the prospective method of

vibration on its own.

Figure 18:

Prospective Vibration and Its Corresponding Motor Speed

To view our full Mesquite Bean

Comparative Analysis, view here.

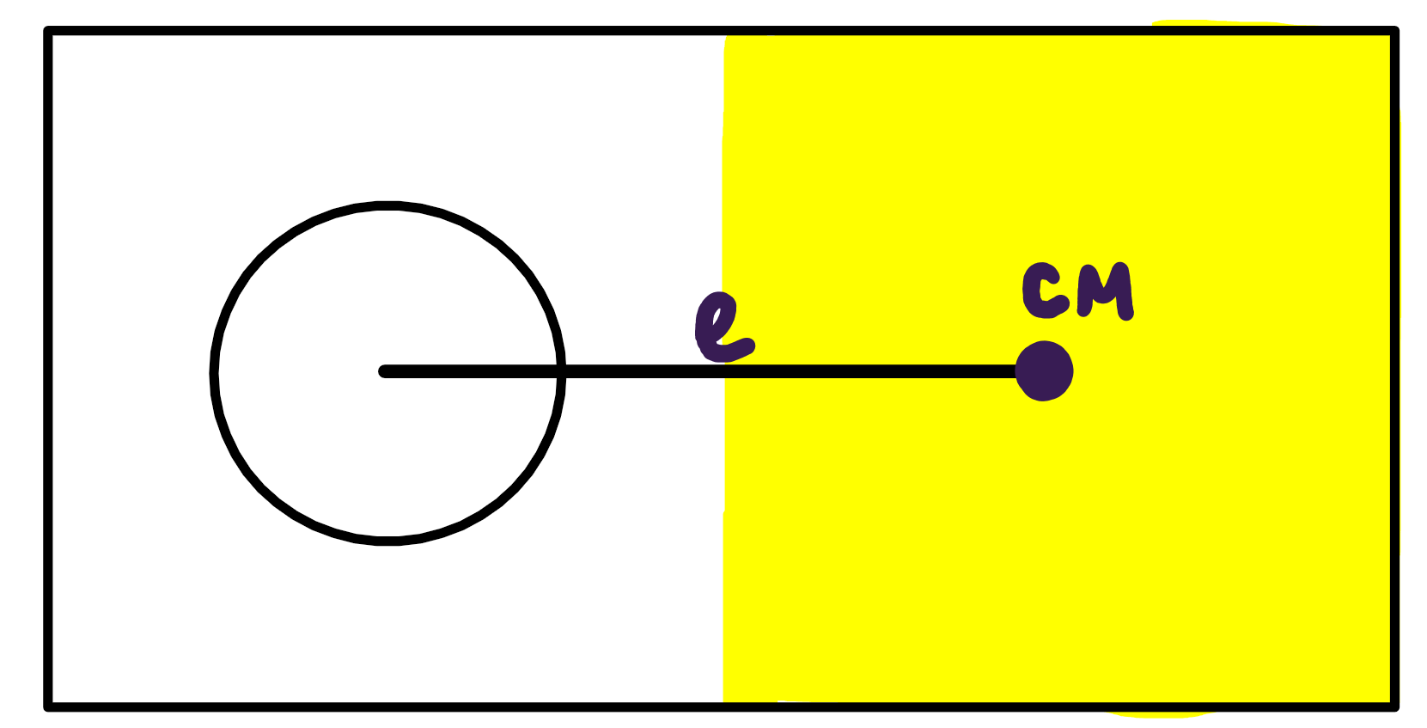

TASK 2: OFFSET

MASS/MOTOR SYSTEM

With knowledge

of Vibrations, an offset mass will be designed and utilized to create a radial

load. [2] Given the following equation:

![]()

Where FT

is the transmitted force, mo is the offset mass (typically the

center of mass of the offset mass), e is the mass eccentricity, and ωdr is the driving frequency. Our offset mass is designed with

the following template:

Figure 19:

Offset Mass Diagram/Template

The radial load generated by the

offset mass and the driving frequency will cause the vibration necessary to

excite the mesquite beans throughout the mesquite branch. The radial load will

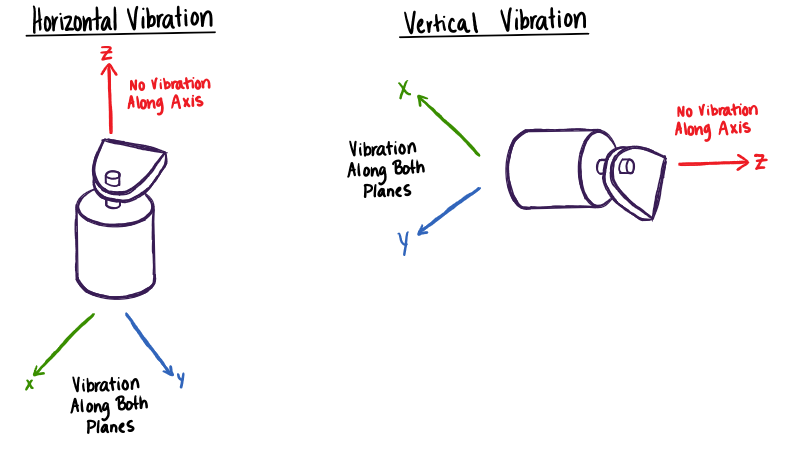

depend on the orientation of the motor, such that:

Figure 20:

Offset Mass/Motor Orientations and Their Respective Vibrations

Horizontal vibration will facilitate

bending and torsional vibrations, while vertical vibration will facilitate

axial vibration. [1] Based on this information, we decided to place the motor

upright to facilitate the bending vibration necessary to drop the mesquite

beans.

TASK 3: BUILD OUR

PROTOTYPES ON SOLIDWORKS

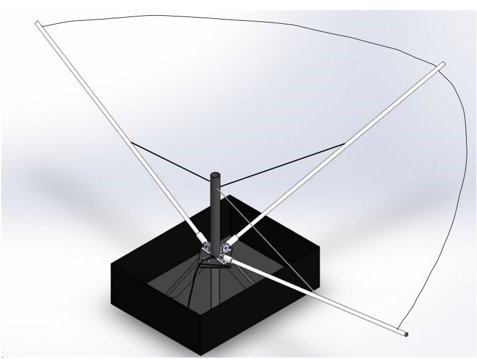

Figure 21:

Excitation - SolidWorks Prototype

Figure 22:

Collection - SolidWorks Prototype

TASK 4: COMPILE A

MATERIAL LIST

To view our Material List, view here.

TASK 5: BUILD OUR

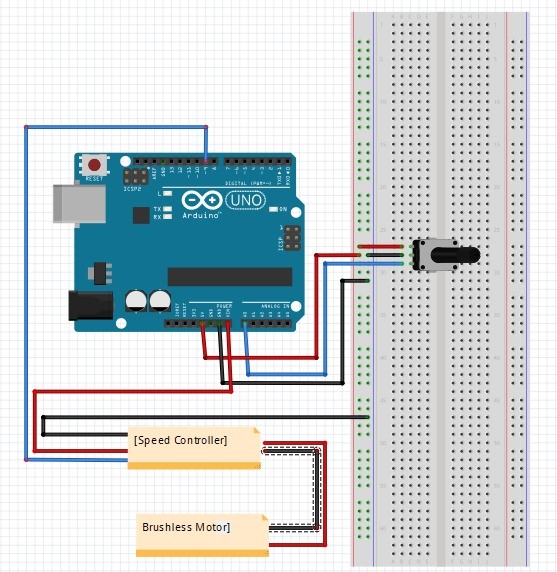

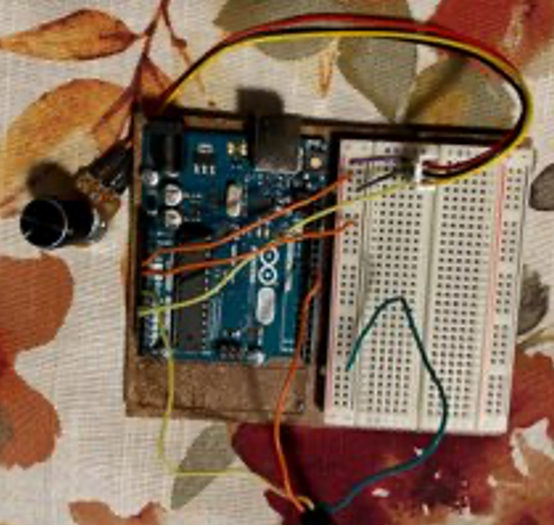

CIRCUIT

Our circuit utilizes an Arduino UNO, connection

wires, a potentiometer, a 400KV DC Brushless Motor, a Speed Controller, and a

rechargeable battery. This circuit will be used to operate the DC Brushless

Motor to create a radial load given by the offset mass.

Figure 23:

Our Theoretical Circuit

Figure 24:

Our Physical Circuit

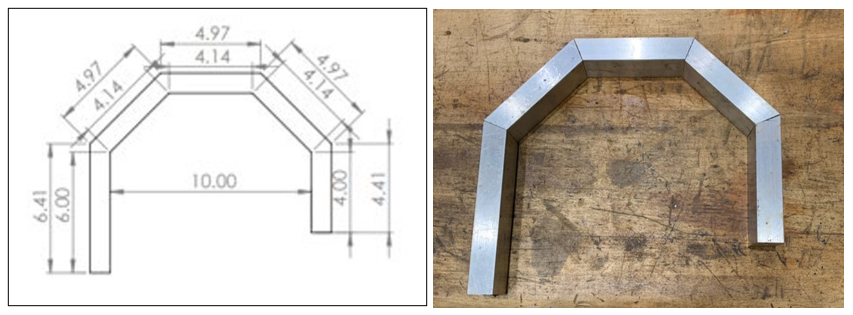

TASK 6: DESIGNING

OUR MOTOR MOUNT

Click on the icon above to see the

Design Process of the Motor Mount!

TASK 7: MANUFACTURING

OUR PROTOTYPES

EXCITATION

Figure 25:

Excitation Hook - From Idea to Reality

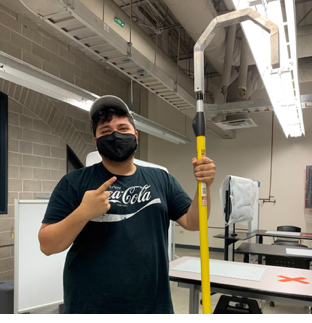

Figure 26: Carlos and Our Assembled Excitation Hook

Click on the icon above to see the

Steps to Use Excitation!

COLLECTION

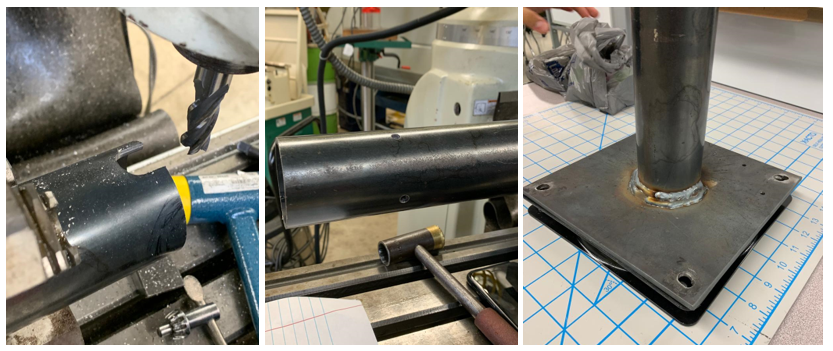

Figure 27: Milling and Welding Our Center Shaft

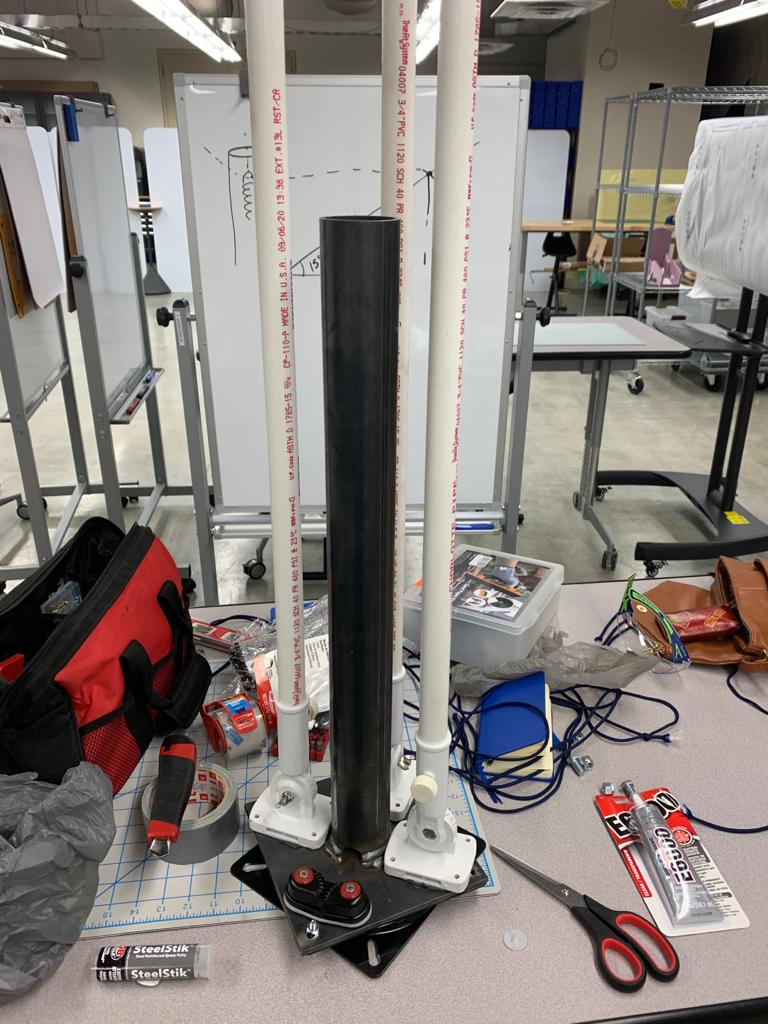

Figure 28: Partial Shaft/Swivel Assembly

Figure 29: Frame/Cart Weldments

Figure 30: PVC/Tarp Assembly

Click the icon above to see our Collection

Tarp Swivel and Retraction!

Click the icon above to see the Steps to Use

Collection!

Figure 31: Both Excitation and Collection in Use

In

this final sub-process, the final design is tested, evaluated, and optimized so

that it can be used to effectively solve the problem identified. After testing

and validation, the final product can be directly led to a higher level of

production.

EXPERIMENT 1

Our goal for

this experiment was to test the vibrational frequencies emitted by the motor with

its off-set mass. Our goal was to simulate a high and low bending frequency of 24.045

Hz (1442.7 RPM) and at least 8.0486 Hz (482.916 RPM) respectively at the end of

the mesquite branch where the beans would naturally grow and develop during

harvesting season.

For our

first experiment, instead of following the chosen design of a hook, we attached

our motor to the tree with a belt to get a closer contact with the tree. This

would provide the least amount of dissipation caused by a branch interface.

Because we were past the bean season, measuring the levels of vibration where

the beans would naturally grow was the next best solution.

To view the

full testing protocol of this experiment, view here.

Figure 32: Alexandra and Stephanie holding the circuit/motor assembly for testing

Click the icon above to see our

assembly exciting the leaves of a mesquite tree!

Figure 33: Phone Used as an Accelerometer for Testing Purposes

We used our cell

phone as a means of recording our data. The app used was called phyphox, which

utilizes the accelerometer within a smartphone to measure the acceleration of

the vibrations transmitted to the end of the branches.

Figure 34:

phyphox - The application used to obtain our vibrational data

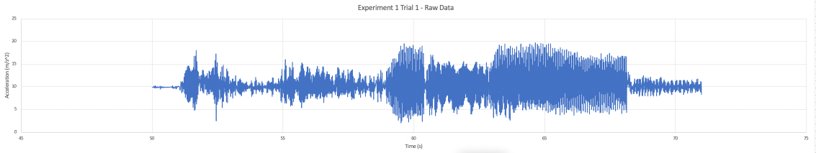

Figure 35: Acceleration vs Time Obtained from Experiment 1

The raw data

collected through this experiment allowed us to create an acceleration vs time graph. Within this

data, one can see the lower peaks in which there is minimal excitation and one

can see the higher peaks that represent the approach to resonance at that

location on the branch of the tree.

With a

signal like the one shown in Figure 31, the approach to this would be to apply a

Fourier analysis to convert the signal from its time domain to the frequency

domain. From there, the dynamic response of the mesquite bean would be

obtained.

After

further analysis of the experiments data, we noticed that by adding the cell

phone to the end of the branch would make a significant difference in the data

we wished to collect. This would change the problem from a cantilever beam to

one with a weight at the end of it therefore making the experimental data

invalid.

EXPERIMENT 2

For the second experiment, our purpose was to test the concept further by simulating the drop of a

mesquite bean due to excitation. However, since the harvesting season had already passed, we looked to an alternative and used rubber

bands simulate the mesquite bean stem being attached to the tree.

Figure 36: Mesquite Bean Suspended onto Branch by Rubber Band

Figure 37:

Image Showing the Mesquite Beans Suspended on a Branch with Rubber Bands

We were

going to replicate the protocol in Experiment 1, but our motor began to

malfunction due to faulty wiring and completely stop working. We were unable to

complete further testing because finding and ordering a new motor was

necessary. However, if our motor had not given out, the vibrational frequency

transmitted from the motor to the bean would have been measured and collected by

analyzing a video of the vibrations in the bean as it fell shot by shot.

Experiment 2 would have provided us with important data which would have confirmed

our FEA analysis on the bending frequencies.

Click the icon above to see our motor

setup for Experiment 2. You will be able to see the motor malfunction.

[1] AB-027 :

Eccentric Mass Parameters For Vibration Motors - Application Notes. (n.d.).

Retrieved March 21, 2020, from https://www.precisionmicrodrives.com/content/ab-027-eccentric-mass-parameters-for-vibration-motors/

[2] Inman,

D. J. (2014). Engineering vibration. Boston: Pearson.

[3] Lesson

2: Problem formulation. (n.d.). Retrieved November 27, 2020, from

http://betterthesis.dk/getting-started/type-of-study . University of Southern

Denmark Library and the Unit for health promotion research. University of

Copenhagen, Department of International Health and Faculty Library of Natural

and Health Sciences

[4] Problem Identification.

(2019, January 02). Retrieved November 27, 2020, from

https://www.cdc.gov/policy/polaris/policyprocess/problem_identification.html

This is a

summary of important Senior Design files, click on each to open in a different

window.

SDI

MIDTERM

FINAL

SDII

REVIEWS

MIDTERM

FINAL