UTRGV / COLLEGE OF ENGINEERING AND COMPUTER SCIENCE / MECHANICAL ENGINEERING DEPARTMENT /

TEAM 3: Mesquite Bean Harvester

(Index Page)

|

Students (L-R) |

·

Carlos Guzman ·

Victoria Garza ·

Stephanie Ramos ·

Alexandra Salinas |

|

Faculty Advisor(s) |

·

Dr. Arturo Fuentes ·

Dr. Joanne Rampersad-Ammons ·

Mr. John Pemelton |

|

Instructors |

·

Dr. Noe

Vargas Hernandez ·

Mr. Greg

Potter |

|

|

|

WHAT IS THE PROBLEM WE

ARE TRYING TO SOLVE?

WHY IS THIS PROBLEM

IMPORTANT?

LEARN MORE ABOUT OUR

DESIGN PROCESS

Welcome! We are Team #3, also known

as “Team 4-I”. Our team consists of four intellectual engineering students,

Alexandra Salinas, Victoria Garza, Stephanie Ramos, and Carlos Guzman. Our

project is the Mesquite Bean Harvester.

Texas has a large population of honey

mesquite trees (Prosopis glandulosa). The bean pods that are grown on these

trees can be made into flour, jams, and jellies, which contain high nutritional

benefits.

Figure 1: Honey Mesquite Beans

However, the current method to

harvest these beans is limited to hand picking and manual labor. This creates a

bottle neck in production due to the low quantity of beans being harvested each

day. We have designed a two-part system that will shake the ripe beans off a

honey mesquite tree and will catch and guide the falling beans into storage.

Our system is divided into an excitation system and a collection system.

As a team, we have worked so hard to

make this work efficiently and effectively. We hope that you enjoy this project

as much as we did.

Watch

our Welcome Video!

Mesquite farmers

in the RGV region need an effective,

mechanized

solution for harvesting mesquite bean pods.

· Given

the current trend for healthier foods and products, the demand for mesquite

bean-based products has increased his calls for a new and efficient way for

harvesting mesquite beans.

· The

current method of harvesting relies on time-consuming, strenuous manual labor,

which has created a bottleneck in productivity.

Figure 2:

The Cappadona Family Harvesting Mesquite Beans

Click

on the icon above to hear our Final Problem Statement!

To better understand the

problem, we conducted background research on the following relevant topics:

·

Complex Biology and Geometry

They can grow to be large

trees reaching 30 ft in height or they can grow short with low branches to

resemble a shrub. Honey mesquite trees are known to thrive in hot and dry

climates and are typically found in North America within the southern states of

the USA. [1]

Figure 3:

Unique Patterns of Mesquite Growth

· Historical

Significance

Back in the indigenous days of the early

Americas, Native Americans would pick beans and use them as a food source,

source of fuel, dyes, structural material, and even alcohol.[2] Because of

mesquite’s ability to thrive in arid environments, Native Americans and

animals were able to eat the bean pods within the

desert. Today, the mesquite tree is seen as an extremely invasive

species, and the mesquite tree’s versatility and applications are not readily

known by much of the public.

Click on the icon above to hear more about the

background of mesquite!

For more information about the historical

significance and uses of mesquite, please click here!

· Information from Cappadona Interview

When beans are ripe, they are ready to be picked

with almost no effort and could fall off with even the smallest gust of

wind. [3] Any ripe beans that are on the trees are to be collected. It is not

possible to collect beans from the bare ground due to contaminants from

animals, pollutants, and molding from the ground. Containers that the beans are

used for collecting must be free from any stones, sticks, branches, and other

debris. Beans that are soaked, dampened, or damaged by water cannot

be milled, and the area must be free of pesticides. The harvest

season for mesquite beans is from early June to late September. [2]

Watch the video below to learn more about the Cappadona Family and their passion for utilizing mesquite!

For more

information and details about the Cappadona Ranch and

their mesquite bean products, view their website here!

·

Safety

Because Mesquite Trees have sharp thorns which protect the

areas where the flowers and beans bloom, if the user does not need to put their

hands into the foliage to pick the beans, the safer they would be. Due to this

need we chose vibration to be what removes the beans from the tree.

Figure 4: Sharp Thorns of a Mesquite Tree

· Competitive Products

Some current solutions hand picking the ripe beans, tree

shakers, and an olive picker. Out of these three methods only one is honey

mesquite specific. Although olive pickers and tree shakers are not made to

cater to mesquite harvesting, they are known to help harvest other fruits and

nuts and can be useful for analysis.

Figure 5:

GOBALYARD Electric Olive Harvest machine and olive shaker for olive picker.

To view this product in its website, click here!

Figure 6: The Cappadona Family Hand-Picking Mesquite Beans

Figure 7: Kadıoğlu EMR400 Walnut Branch Shaker Harvesting Machine

To view this product on its website, click here!

Our main motivation to work on this

mesquite bean harvester is to help create alternate methods of food resources. With

the Earth’s ever-increasing population, alternate methods of food

resources are important to investigate to discover how one can

nutritionally thrive during environmental and social disasters, such as

droughts, food shortages, etc.

With this

concept in mind, using mesquite beans is now more prominent within

the American Southwest and is trying to be pushed towards the public.

Seeing the importance of the problem, the next step would be to identify

exactly who is affected by the problem and at the same time, describes how our

proposed solution can affect not only the user but other affiliated parties.

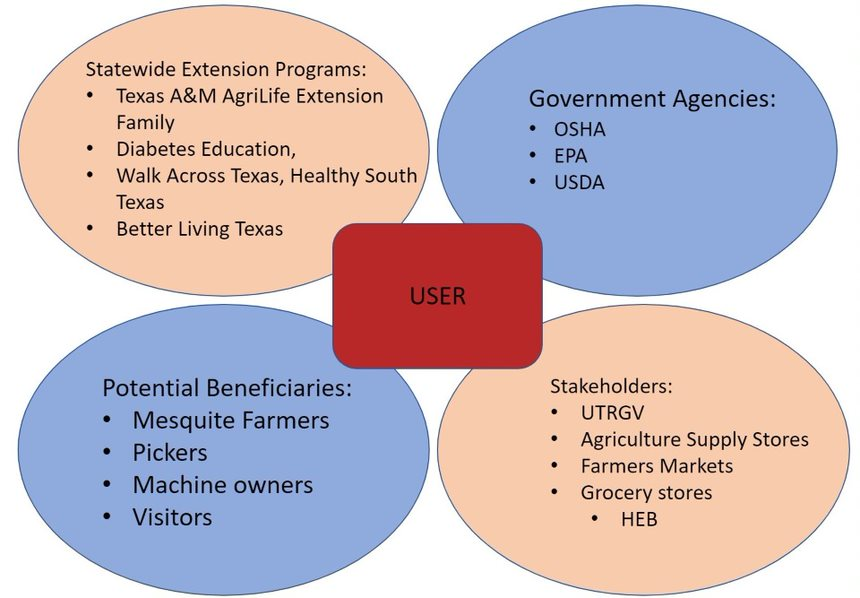

Figure 8: Our Stakeholder Map Conveys the Types of Users that Would Benefit from Our Product

Our

stakeholder map above shows us the people and businesses that will be directly

affected by the decisions made for our designs. With the importance of our

problem statement, we also must consider those affected, with the user in the

center. Moving forward, the solution that must be considered will have to

benefit all parties affected, either directly, or as an effect of our solution.

“We propose the design of a two-part

system that will both remove the beans safely from tree and collect them for

the final stages of the harvesting process.”

After understanding the problem in

depth, we explored various potential solutions and selected the best concept.

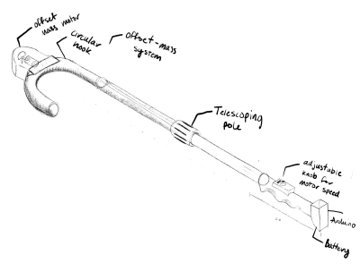

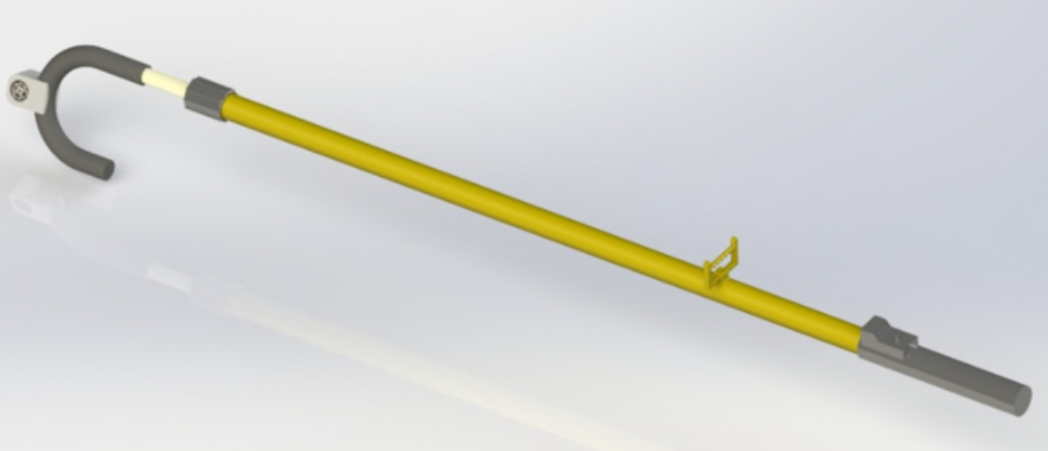

This is how our product solution works: the excitation, hook device will excite

the beans at the end of the trees which will fall into the awaiting collection

tarp. Once hitting the tarp, the beans will pool together at the bottom of the

cart.

Figure 9: Excitation Prototype Sketch

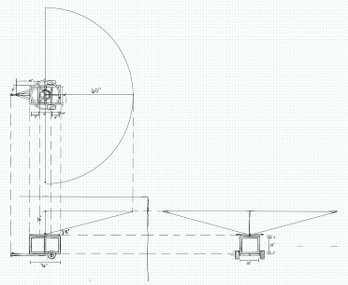

Figure 10:

Collection Prototype Sketch

Once we defined a clear solution idea

(i.e. concept), we applied our engineering knowledge to transform it into a

real product. These were some of the important design challenges and how we

approached each one of them:

Excitation System:

The solution of using

vibrations is not a new one in agricultural engineering. As mentioned before

there are many forms of excitation that can be used to shake fruits or nuts

down from a tree. The team investigated multiple sources such as frequency and

amplitude of almonds [4], and the experimental studies of apple vibration

harvesting. [5] With these academic papers in mind, we can begin our approach

mathematically for vibrational design.

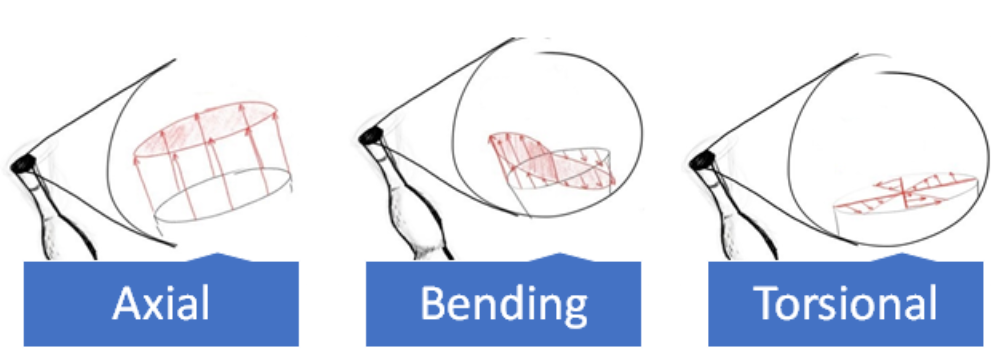

Before designing the hook, we needed

to identify the best mode of vibration to use to cause the beans to drop. We

investigated torsional, bending, and axial vibrations, studying the types of

stresses they produced at the stem of each bean.

Figure 11:

Types of Vibration and Their Stress Concentrations

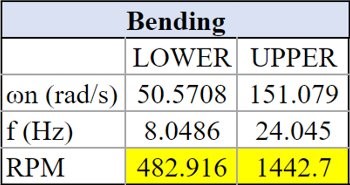

After extensive analysis we

determined that causing bending vibrations would create an optimal design due

to the low frequency required to make the bean’s stem reach its natural frequency.

Figure 12:

Prospective Vibration and the Range of Frequency Needed to Drop Mesquite Beans

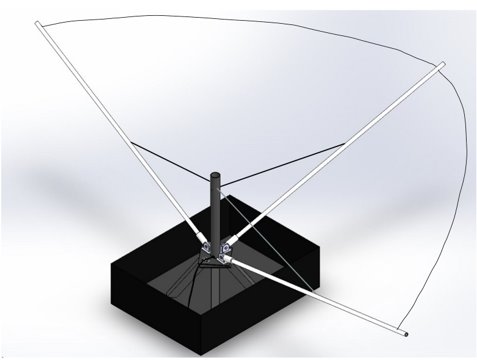

Collection System:

The system itself would

be inspired to many agricultural solutions that are applied in other harvesting

methods. Specifically, the general idea of the collection of the mesquite bean

pods relies on several design challenges that were set up due to the complex

geometry.

1.) The

device height must have a low profile since the mesquite tree branches ranges

from high to reaching down to human height. By approximating the height of the

shortest branch of a sample of trees, the average was collected to determine a

height reference.

2.) The

material of the collection system catching the beans needs to be robust enough

to handle puncture forces from falling beans. A thorough material selection was

done to ensure that the material has a longer lifespan.

3.) Since

the collection system will have to be on a large ranch and spans land several

acres, the device must be robust enough to carry and harvest.

4.) The

angle of the tarp should change as desired by the consumer to adjust to

different canopy heights.

5.) The

cart itself should be able to reposition its rotational position with ease.

We found that physical prototyping was

extremely helpful to increase our understanding of the problem and the

feasibility of our solutions. Our first prototypes were simple but useful and

we continued evolving into more complex ones.

This was our first prototype; it may

be simple, but it helped us understand how using an offset mass attached to the

shaft of a brushless motor would create such elevated levels of vibrations.

EXCITATION

Figure 13: First SolidWorks Prototype – EXCITATION

Figure 14: Second SolidWorks Prototype – EXCITATION

COLLECTION

Click the icon above to see a video of our First SolidWorks Prototype for Collection!

Figure 15:

SolidWorks Prototype - COLLECTION

After much work, this is our final product:

Figure 16: Both Excitation and Collection in Use

The following figures and videos show

the different systems and how they work individually and cohesively!

Figure 17:

Animation of Our Products in Use. Created by Carlos Guzman.

EXCITATION

Click

on the icon above to watch the Steps to Use Excitation!

COLLECTION

Click

on the icon above to watch the Steps to Use Collection!

Click

on the icon above to watch our Tarp Retraction and Swivel!

TESTING

AND VALIDATION:

In this final sub-process, the final

design is tested, evaluated, and optimized so that it can be used to

effectively solve the problem identified. After testing and validation, the

final product can be directly led to a higher level of production.

To begin testing, the team prioritized towards the effects of

vibrations our offset motor has on the bean pods.

EXPERIMENT 1

As a team, we sought to test our offset mass motor circuit on a

mesquite tree. We took unconventional measures to get the motor onto the tree.

Figure 18:

Alexandra and Stephanie holding the circuit/motor assembly for testing

Figure 19:

Phone Used as an Accelerometer for Testing Purposes

We used our cell phone as a means of recording our data. We used

the app phyphox, which utilizes the accelerometer

within a smartphone to obtain pertinent data related to excitation.

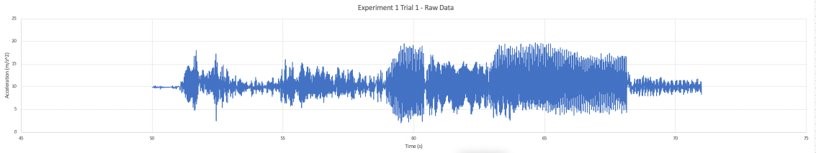

Figure 20:

Acceleration vs Time Obtained from Experiment 1

For this experiment, we obtained data within an acceleration vs

time graph. Within this data, one can see the lower peaks in which there is

minimal excitation and one can see the higher peaks that represent the approach

to resonance at that location on the branch of the tree.

With a signal like the one shown in Figure 19, the approach to

this would be to apply a Fourier analysis to convert the signal from its time

domain to the frequency domain. From there, the dynamic response of the

mesquite bean would be obtained.

Although this data was not perfectly accurate because of the

factor of the weight of the cell phone, using a lightweight accelerometer will

allow us to gather useful data in the future.

EXPERIMENT 2

For the second experiment, we wanted to prove our concept further

by simulating the drop of a mesquite bean due to excitation. However, given the

time of year and the passing of our harvest season, we looked to an alternative

and used rubber bands to drop the mesquite bean.

Figure 21:

Mesquite Bean Suspended onto Branch by Rubber Band

Figure 22:

Image Showing the Mesquite Beans Suspended on a Branch with Rubber Bands

We were going to follow the exact same protocol as in Experiment

1, but our motor began to malfunction and completely stop working. We were

unable to complete further testing because finding and ordering a new motor was

necessary.

Our project is a proof of concept that requires further

development, these are some of the pending items:

·

In

the future we would like for our prototypes to be tested during the Harvest

Season.

·

A

vibrational system can be created to improve movement of the tarp material to

convey the beans falling form the tree into the bins.

·

We

would want to replace our d/c motor wire connections and implement a Bluetooth

motor to create a more maneuverable extension arm without any interference from

electrical wiring.

·

We

wanted to fabricate our own cart to ensure stability and make the project 100%

made by us but given our budget and how we did not want to reinvent the wheel

we went with a prefabricated cart that was low-quality.

·

We

would like to implement the use of a low-weight accelerometer during testing to

accurately obtain frequencies experienced at the stem of the bean due to

applied vibrations from the motor without severely changing the properties of

the experiment.

·

The

process of replacement or removal of the tarp can be optimized and, ideally,

the process should be simplified for the sake of the consumer.

·

In

the future we would like to redesign our tarp to be wind resistant and

stationary when it is fully expanded.

·

As

a team, we know that the level of this project is not at its highest potential.

We feel that the best option would be to pitch this wonderful project to a

prospective senior design team.

Click

Here to hear about the details of our Future Work.

IN CONCLUSION

The senior design process was a challenge to implement all the

core fundamental engineering lessons that were learned in the classroom. With

the knowledge we possessed, we, as a team, created a prototype that serves as

an excellent steppingstone to the project. There were many design choices that

were made during this project that we believe to be innovative and can

certainly be expanded on.

Figure 23:

[Left to Right] Stephanie Ramos, Victoria Garza, Alexandra Salinas, and Carlos

Guzman Proudly Showcasing Their Final Senior

Design Products

As a team we faced many trials throughout the course of

Senior Design 1 and Senior Design 2, both in our academia life and in our own

personal lives. With the current COVID-19 pandemic, it is safe to say that our

team has made remarkable steps towards making a complete product that can be

used for the Cappadona Ranch and for their growing

business venture in the agriculture business. As the project continues to grow

and expand with innovative ideas, we expect that the final product can become

something that is innovative in the honey mesquite bean picking process.

We would formally like to thank you for viewing our website.

Without the unwavering support of every single one of you, this project would

not be as successful.

Click on the icon above to watch our

Conclusion!

REFERENCES

[1] Bovey, R., 2016, Mesquite, Texas A & M University

Press, College Station.

[2] DesertUSA.com, 2020, "Cooking with Mesquite Beans - DesertUSA", Desertusa.com [Online]. Available:

https://www.desertusa.com/lil/Mesquite-Beans-recipes-lil.html. [Accessed: 02-

Dec- 2020].

[3] Cappadona, Victoria, and Justin Cappadona. 2019. Review of Cappadona

Ranch: Mesquite Harvesting Interview by Carlos Guzman, Alexandra

Salinas, Victoria Garza, and Stephanie Ramos. https://utrgv-my.sharepoint.com/:u:/g/personal/victoria_a_garza02_utrgv_edu/EdMcC_LdGEFFk81TAuIH9a4B-SpY5AZQ2NRpi-7SNlT6iw?e=csbyx5.

[4] Loghavi, M. & Khorsandi,

Farzaneh & Souri,

Saman. (2011). The Effects of Shaking Frequency and Amplitude on vibratory

harvesting of Almond (Prunus dulcis L. cv. 7Shahrood). American Society of

Agricultural and Biological Engineers Annual International Meeting 2011, ASABE

2011. 3. 10.13031/2013.37424.

[5] Ming Liu, Fenglei

Wang, Haiqian Xing, Wenli Ke, Shaochun Ma, The

Experimental Study on Apple Vibration Harvester in Tall-spindle Orchard,

IFAC-PapersOnLine, Volume 51, Issue 17, 2018, Pages

152-156, ISSN 2405-8963, https://doi.org/10.1016/j.ifacol.2018.08.079.

(http://www.sciencedirect.com/science/article/pii/S2405896318311959)

We went

through a meticulous design process to arrive to the final solution. The

information in this page is a summary intended for the general public. To learn

about the project details, visit the DESIGN PROCESS page. To obtain

access contact the course instructor.

The team

received help from various persons, their help was critical to our success, we

would like to acknowledge:

Instructors:

· Dr.

Noe Vargas

· Mr.

Gregory Potter

Faculty Advisors:

· Dr.

Arturo Fuentes

· Dr.

Joanne Rampersad-Ammons

·

Mr. John Pemelton

Hi-bay Staff and Manufacturing

Assistance:

· Mr.

Hector Arteaga

· Mr.

Jose Sanchez

· Jared

Martinez

· Bryant

Salinas

· Santana

Gutierrez

· Kane

Samoso

· The

Department of Mechanical Engineering

Collaborating Business Team:

· Sylvia

Robles

· Yasena Cantu

· Fernando

Ramirez

· Moises

Davila

· Gerardo

Reyna

· The

Cappadona Family