UTRGV / COLLEGE

OF ENGINEERING AND COMPUTER SCIENCE / MECHANICAL ENGINEERING DEPARTMENT

TEAM 1: REDESIGN OF A FILTER SYSTEM FOR INDUSTRIAL

MACHINING FLUIDS

(Design Process Page)

|

SDI

Students (L-R) |

· Karla Mariel Morales · Julio Deleon · Ramon Sanchez · Marissa Sandoval |

|

Faculty

Advisor(s) |

· Martin Johansson · Mostafa Malki |

|

Course

Instructors |

· Dr. Noe Vargas Hernandez · Mr. Greg Potter |

Back to the PROJECT

MAIN PAGE.

During

Senior Design we followed a design process

Problem ID

Problem Formulation

Conceptual

Design

POG

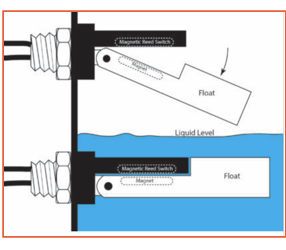

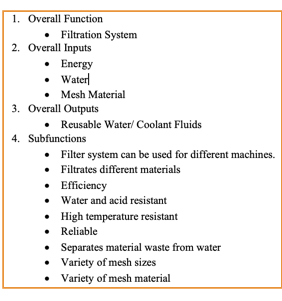

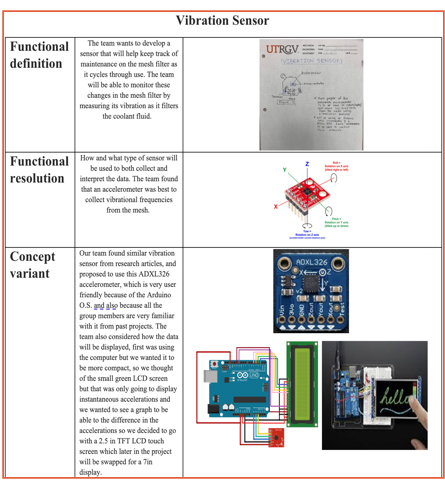

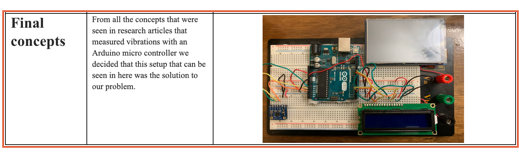

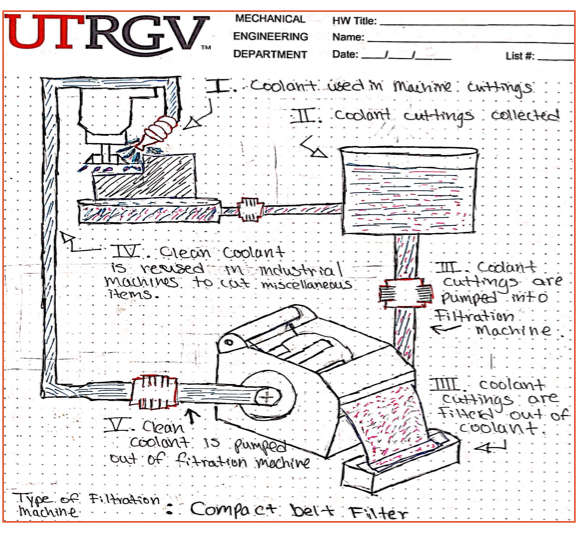

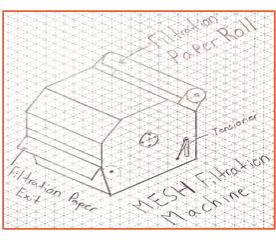

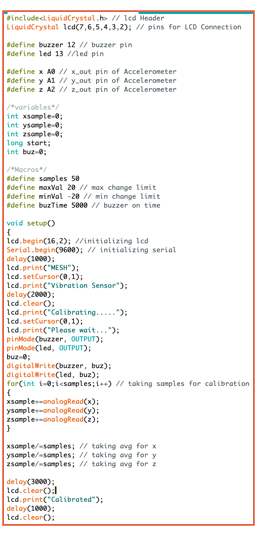

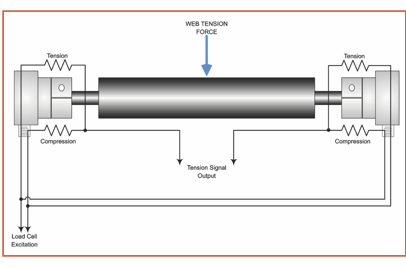

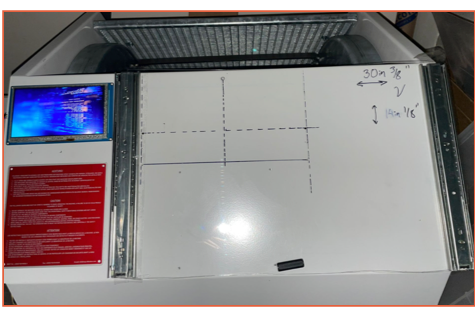

Our preliminary idea is to use a

combination of different sensors that could foresee when the mesh filter is about

to fail or need of service which if not addressed at the appropriate moment can

lead to making the filtration machine come to a complete stop. Next would be

investigating and improving the signal response of the coolant/fluid leveling

sensor system, which sometimes causes inaccurate readings due to some

coolants/fluids making foam during the filtration process. And if not addressed

this can lead to using excessive amount of filtration paper which tends to be

expensive.

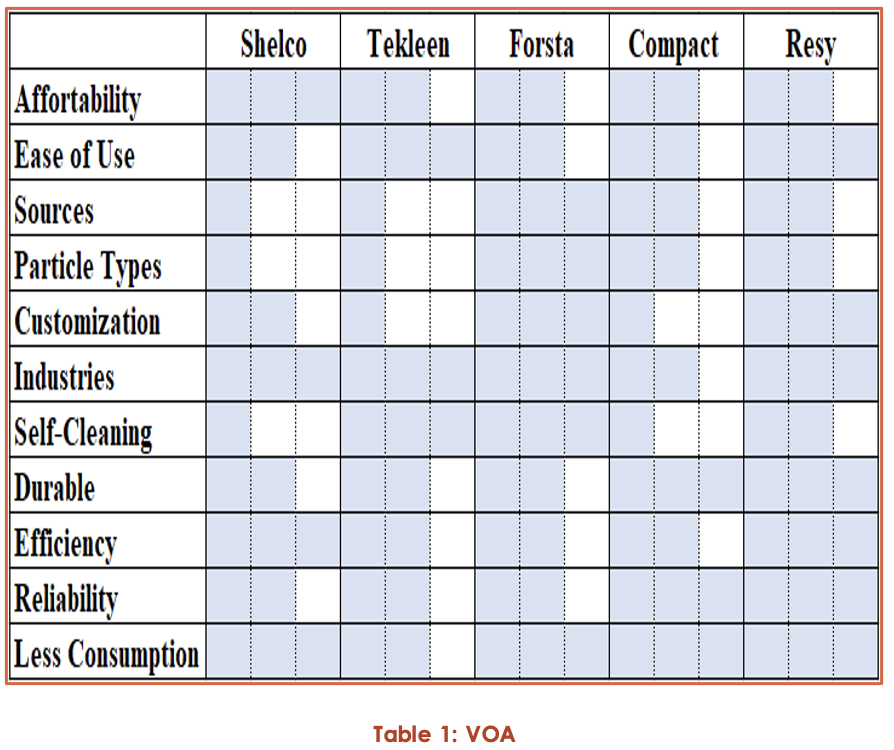

VOA

When compared to the competitors, our product offers

affordability, ease of use and efficiency.

1. Affordability:

Our product is affordable to the companies and users.

2. Ease

of use: The function of the filter system will be simple in

order to allow the user to fully understand how to utilize the

machinery. There would also be an improvement in the aesthetics of the filter

machine by using meaningful tactics in the design to ensure we grab the user’s

attention.

3. Sources:

The filtering machine is designed to filter different type of sources.

4. Particle

Types: The filtering machine is designed to increase the efficiency in removing

various types of particles from the different materials.

5. Customization:

The design of the filter system is based on meeting the needs of the user.

6. Industries:

There are various industries that utilize and rely on the Resy

Filtering System.

7. Self-Cleaning:

The filtering machine is designed to self-clean and requires low maintenance.

8. Durable:

It is a durable product since it requires low maintenance.

9. Efficiency:

The product is very efficient in removing any particles by using the filtering

system.

10.

Reliability: It is a reliable product since

it is very efficient and functions properly.

11.

Less Consumption: The design of the filtering

system will allow for the product to decrease the amount of filter paper

consumption.

BACKGROUND RESEARCH

Filters have been a

crucial part of our human history. Believe it or not, ancient civilizations

used a variety of techniques to filter out unwanted substances/impurities for

things like drinking water. The earliest record of how humans used filters, dates back to around 500 B.C. where the Greek scientist

Hippocrates invented the so-called Hippocratic sleeve, which consisted of a

simple cloth back filter. After that there's records of the Egyptian

civilization at 400 A.D. using a variety of methods to eliminate harmful

bacteria from there drinking water, like I mentioned previously they used

several techniques such as boiling the water, heating it in the sun, or

submerged a hot iron into it. They also filtered impurities from their water by

sifting it through sand and gravel. And obviously as time went on so did the

innovation of humans, discovering filtration methods of separating the salt

from sea water to more complex things like being able to purify contaminated

water with the method of chlorination in the mid 19th Century. Now

currently with modern technology, humans have pushed the boundaries of

filtration towards the sky, from coffee ground bean filters to filtering metal

cuttings from the coolant that is used in machinery.

Furthermore, there is

an abundant amount of filtrations systems. All of them having their specific

area of filtering for example, the method in which how they filter, different

types of filtering material, and what type of objects/impurities the filtration

system will filter. With this is mine, the team has collaborated in defining

these different things and has made them into various categories which will

give an insight to these filtrations systems.

First category: Filtration

Methods

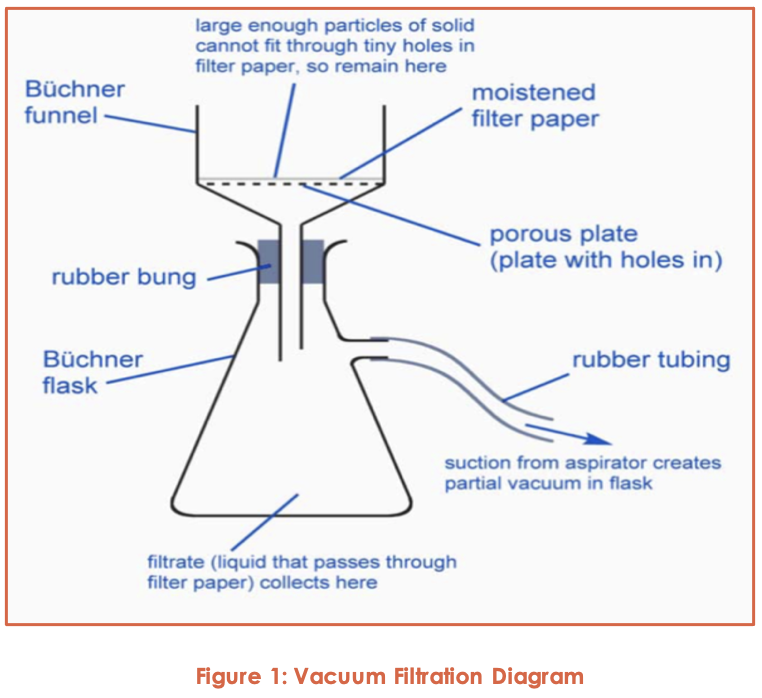

Vacuum Filtration

First and foremost,

the primary purpose of this method of filtration device is to distinguish

solids from liquids. The key benefit of this method of filtration is that it

incorporates negative pressure at the filtrate outlet. There are two distinct

types of filtering; sporadic filtration, which is ideal for thin solutions, and

constantly working filtration, which is optimal for treating viscous impure

powders.

A mechanically

pressed filter has been produced in order to produce a filter residue with a

low moisture content. A basic filter press is made by separating the container

into upper and lower chambers using a filter medium. The suspension is applied

to the upper chamber and reaches the lower chamber under strain through the

filter medium, forming a filtrate, with the rigid particles stuck on the filter

medium's surface forming a filter residue (or filter cake).

The filter residue

layer on the surface region of the filter medium steadily thickens during the

filtration process, raising the resistance of the material flowing through the

filter residue layer and reducing the filtration speed. Filtration is halted,

the filter residue is discarded, and the filter medium is regenerated to

complete a filtration cycle when the filter chamber is loaded with filter residue,

or the filtration speed is too slow.

To conquer the

resistance, the liquid must flow between the filter cake layer and the filter

medium, which requires a pressure gap on both sides of the filter medium, which

is the guiding force for filtration. While raising the pressure differential

will speed up filtration, the particles deformed after being pressed are more

likely to block the pores of the filter medium when the pressure is strong,

resulting in slowed filtration. Slag layer filtration, deep filtration, and

sieve filtration are used to filter the suspension. The term "filter

residue layer filtration" refers to the formation of the original filter

residue layer during the first step of filtration. Following that, the filter

residue layer performs a vital function in filtration. Both large and small

particles are trapped during this time; deep filtration indicates the filter

medium is dense and the suspension includes both large and small particles.

There are less stable objects, because the particles

are smaller than the filter medium's pores. The solid particles trapped by the

filter are larger than the pores of the filter medium, and the inside of the

filter medium does not adsorb the solid particles after they have been

filtered; the sieve filter is the solid particles trapped by the filter are

larger than the pores of the filter medium, and the inside of the filter medium

does not adsorb the solid particles after they have been filtered. The coarse

impurities in sewage are filtered out using filtration systems such as a tumble

filter screen.

The three approaches

are often used concurrently or sequentially throughout the actual filtration

operation. The filtration speed determines the filter's processing power. The

pores of the filtered filter residue layer are reasonably smooth while the solid

particles in the suspension are wide and standardized in size, and the filtrate

flows through the filter residue layer at a relatively high pace. The usage of

a coagulant to aggregate fine particles into larger agglomerates assists in the

speeding up of the filtration process. The filter applied in the upper part of

the filter medium is applied so that the filtration direction is consistent

with the direction of gravity, and the coarse particles are first settled,

which can reduce the clogging of the filter medium and the filter residue

layer; in the difficult-to-filter suspension ( If the solid particles settle

quickly), the filter applied in the upper part of the filter medium is applied

so that the filtration direction is consistent with the direction of gravity,

and the coarse particles are first settled, which can reduce the clogging of

the filter The filtration method can be sped up with these steps.

(The principle of vacuum filtration[Hawach Scientific])

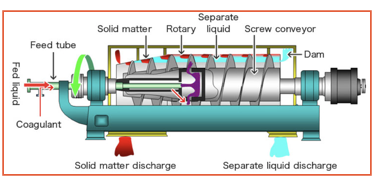

Centrifugal Filtration

Antonin Prandtl is

credited with inventing this method of filtration device in 1864, which was

used to isolate milk and cream on a wide scale. Later, Swiss physician and

biologist Friedrich Miecher exposed him to research

labs for the first time. Furthermore, centrifugal separators are propelled by

the centrifugation method. Centrifugation separates ions from a solution by

using centrifugal energy. This method is usually used to isolate two immiscible

liquids in a solution.

An inlet, exhaust, and separator are also used

in the centrifugal separator. The combination of liquid and strong, solid and

liquid, or gas and solid is poured through the separator's cone-shaped

operating apparatus. The separator induces a revolving vortex, which enables

solids to be filtered from liquids. The solids that have been removed are

deposited at the bottom of the separator and purged. The contaminant and

high-density liquid flow out of the separator, while the low-density portion

stays inside. Since water is one of the denser substances, it passes outside

and is drained into an outlet. Lower density fluids, such as gasoline, will, on

the other side, stay at the core of the vortex. The extracted oil can be

quickly retrieved from the separator's suction orifice.

(The

principle of vacuum filtration. (2018, September 06). Retrieved February 27,

2021, from https://www.vacuumfiltrations.com/the-principle-of-vacuum-filtration/)

Also, centrifugal separators are available in different designs

and capacities. Depending on their designs, they are utilized in different ways

across various industries. Here are some applications of the filtration system.

·

Pre-Filtration:

The centrifugal separator helps improve the efficiency of filtration as well as

minimize liquid loss when it is used for pre-filtration. This pre-filtration

helps users save on expensive water treatment solutions.

·

Protecting

Heat Exchangers: They help protect heat exchangers effectively against fouling.

Centrifugal separators can remove scale and suspended grit easily.

·

Protecting

Spray Nozzles: Centrifugal separators are also used for protecting spray

nozzles and small orifices in various industrial applications. How? These

separators help remove solids that clog the nozzles of the spray. This, in

turn, helps reduce the wear and tear of the nozzle, as well as avoid its

regular replacement.

·

Reducing

Industrial Waste: As known centrifugal liquid separators are designed to remove

solids from a liquid. This becomes advantageous in case of applications, where

the disposal costs are high, or where recovery of high solids is mandatory.

This also helps improve the life of seals.

(Centrifugal separators

[Cannon, D., & Cannon, P.])

Figure

2: Centrifugal Separator Diagram

The disparity in

specific gravity between the liquid and the solid being filtered defines the

effectiveness of centrifugal separation. If the gap is high, the separation

efficiency can boost. The particle size has an effect on

separation efficiency. The visibility requirement for most separators is set at

40 microns.

Apart from being used in a

number of industrial applications, there are many drawbacks to utilizing

this form of filtration device, as well as several applications in which it is

used.

·

Maintenance Free: The centrifugal separator is largely

maintenance-free owing to the absence of moving parts or other components. It

is fitted with an automatic purge valve designed to flush the debris and

contaminants automatically.

·

Minimal or No Downtime: This is another major advantage of

centrifugal separator water filters or centrifugal separators used in the

industrial process. As the filtration is performed by the spinning of a vortex,

there are no real filters involved. This means there will no accumulation of

debris in filters, and there will no breakdown due to this accumulation. Also,

there will no need to change the filters more often, as in the case of other

liquid separators.

·

Minimal Liquid Loss: Do you know there is a little liquid loss

by purging while using centrifugal separators than other filters! Typically,

the users have to bear major liquid loses when

cleaning sand media filters or automatic strainers.

·

High Efficiency: The efficiency of centrifugal separation is 98%

of 40 microns in a single pass. However, for centrifugal separator, this is 44

microns. This stands valid for solids at the gravity of 2.6 and water at 1.0.

·

Environmental Processes: A centrifugal separator is used in

various environmental processes for industrial and municipal wastewater

treatment. It is widely used for separating biomass and animal slurry from

water.

· Recycling: Water

impurities are one of the main concerns of various recycling plants. These

centrifugal separators are used for treatment and recovery processes at recycling

plants. They are widely used for recycling service water in various industrial

processes.

· Plastic and Chemical

Processes: In the chemical industry, water is used in various phases of

chemical manufacturing. Various types of byproducts are generated during

chemical processes which may get mixed with water, thereby polluting the water

stream. The industrial centrifugal filters help avoid contamination of water

streams and recover intermediate or end products during the process.

Centrifugal separators are also used during plastic manufacturing. They find

great applications during PP, HDPE, and PVC polymer production. Similarly,

these filters are used in minerals and ores production, pharmaceutical and

biotechnology sectors, and during the production of non-fossil fuels, among

others.

· Food and Beverage

Production: This industry uses a lot of water and also

releases byproducts during various production processes. This is where

centrifugal separators can help. They are used during the processing and

recovery of non-liquid food products, fruit and vegetable juice production,

wine and sugar processing, among others.

· Oleo-Chemistry:

Several byproducts are generated during the production of oleo-chemistry

derivatives. They can be easily filtered using centrifugal separators. These

separators are also used for refining edible vegetable oils. However, they are

not recommended to use during the refining of olive oil.

· Mineral Fuel and

Lubricating Oils: Industrial centrifugal filters are used for purification and

conditioning of fuels, purification of lubricating oils, and treatment and

recovery of various fuel oils. They are also used for the treatment of

slop-oils from lagoons or refineries or bilge water.

· Animal-based

Products: The meat and fish processing create lots of useful and non-useful

byproducts. The centrifugal separators are used for the treatment of byproducts

from meat and fish processing industries.

(Centrifugal separators [Cannon, D.,

& Cannon, P.])

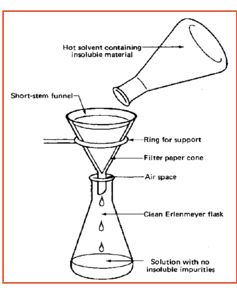

Gravity Filtration

When it comes to extracting solid

impurities from an organic liquid, gravity filtration is the tool of option. A

drying agent, an unnecessary side product, or a residual reactant may both be

impurities. While gravity filtration may be used to capture solid substance,

vacuum filtration is most often used since it is quicker. To remove insoluble

impurities from a hot fluid, a filtration technique known as "hot gravity

filtration" is used. Fluted filter paper and close attention to the

process are needed for hot filtrations in order to maintain the apparatus warm

yet protected so that the solvent does not evaporate. In organic chemistry

teaching laboratories, hot gravity filtrations are no longer used in standard

procedures for studies.

When scraping the solid precipitate to remove the filtrate, the

liquid, for further function or examination, a simple filtration under gravity

is used. Filter paper, filter funnel, retort stand to set and carry the funnel,

and a conical flask to collect the filtrate are the tools used for this

filtering technique.

(What is the difference between vacuum filtration and gravity

filtration? (2020, January 18). Retrieved February 28, 2021, from https://www.labrotovap.com/what-is-the-difference-between-vacuum-filtration-and-gravity-filtration/ )

Figure 3.

Gravity Filtration Diagram

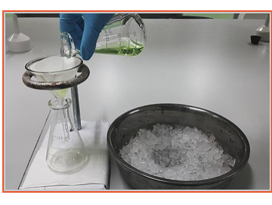

Cold Filtration

The cold filtration process involves using an ice bath to quickly

cool down the crystallization solution rather than setting it out to cool down

at room temperature. This process creates very small crystals, as opposed to

huge crystals, which can be produced by cooling the solution to room

temperature.

(Filtration. (2021, January 16). Retrieved February 28, 2021,

from https://en.wikipedia.org/wiki/Filtration )

Figure 4.

Cold Filtration demonstration

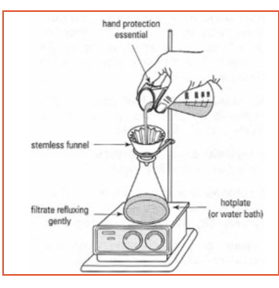

Hot Filtration

The hot filtration method's primary

objective is to remove solids from a hot solution. This is achieved to avoid

the development of crystals in the filter funnel and any equipment that comes into contact with the solution. As a

consequence, the equipment and the solvent used are heated to avoid a

sudden drop in temperature, which would cause the solids in the funnel to

crystallize and obstruct the filtration method. The usage of a stemless filter

funnel is one of the most critical steps in avoiding the creation of crystals

in the funnel and maintaining successful hot filtration. Owing to the lack of a

stem in the filter funnel, the surface area of interaction between the solution

and the stem of the filter funnel reduces, preventing re-crystallization of the

solid in the funnel and negatively impacting the filtration mechanism.

(Filtration. (2021, January 16). Retrieved February 28, 2021,

from

https://en.wikipedia.org/wiki/Filtration )

Figure 5. Hot

Filtration Diagram

Gravel Filtration & Multilayer Filtration

Gravel filtration is a deep-bed

filtration process that uses a multi-layer filtration device (filter gravel +

filter carbons). Water passes through multiple layers of filter content with

increasing fineness in the direction of filtration through multi-layer

filtration. Based on the size of the soil, it is agglomerated in the different

layers of the filter. Significant volumes of solids may be absorbed by

multi-layer filters. Gravel filtration, commonly known as multi-layer

filtration, is used in combination with flocculation to filter river water.

Filtration is often followed by a sedimentation stage as the first phase step

in these situations. Back-flushing is used to disinfect gravel and multi-layer

filters on a daily basis.

Furthermore, depth filters

(Sutherland, 2011) are porous filtering mediums made up of cellulose fibers and

inorganic absorbents that are used in multi-layer filtration. They can maintain

pollutants through the thickness as well as on the surface during liquid

filtration, unlike surface filtration. In a common medium, these hybrid systems

incorporate two distinct separation concepts and technologies. Filtration by

particle rejection is accomplished by creating an intricate mesh in which a

practical inorganic particle performs selective adsorption. Separation can be

increased still further by adding other additives to the network, such as

charged polyelectrolytes (Dizge et al., 2011). A

cationic polymer that adsorbs the typical negatively charged dissolved

pollutants in a far smaller pore size than the normal pore size may be added to

the medium. However, most depth filtration studies in the literature have

concentrated on membrane separation modeling (Polyakov, 2008, 2009; Sutherland,

2011; Kuhn and Briesen, 2016; Bedrikovetsky

et al., 2017; Goldrick et al., 2017); there are few

experimental studies optimizing depth style filter activity, especially in

terms of membrane structure.

Controlling filter structure/composition

and operating mode will tailor filtration efficiency in a variety of ways.

Dead-end filtration and cross-flow filtration are two

effective types of service, with the flow passing directly through the filter

in dead-end and tangential to the filter in cross-flow filtration (Liderfelt and Royce, 2018). These processes may also be

regulated using constant pressure or constant flow rate modes. In any case, the

non-constant parameter is tracked, and the reported parameters are used to

determine the degree of filter fouling or clogging (Iritani

et al., 2015; Goldrick et al., 2017). Modifying the

composition and configuration of filters may also improve filtration

efficiency. Multi-layer layered filters of different pore sizes stacked on top

of one another provide an easy way to separate cells or particles in a

sequential manner (Saefkow, 1995; Rijn, 1998).

Filtration was modeled on a multi-layered membrane system with each layer

having different pore sizes stacked on top of one another in a recent analysis by

Griffiths et al. (Griffiths et al., 2016). The effectiveness of a multi-layered

filter structure was investigated using a model that simulates particle

transport and filtration via a multi-layer structure. This model describes the

filter and gives recommendations for the number of filter layers, pore size in

each layer, and pore interconnectivity between layers.

Filtering bacteria using

multi-layered filters to increase bacterial capture has also been documented

(Koch, 1984). Through mechanically adding one sheet to another, which includes

a bacteria-destroying substance, the researchers hoped to achieve higher

bacteria rejection. A nano fiber film was added to the original layer of a

fibrous filter in another analysis (Wertz and Guimond,

2014). Filter media with a first layer adhered to it and a nanofiber layer

adhered to it had beneficial properties, such as improved dust keeping ability.

Despite the fact that

multi-layered filters are commonly used in industry, few studies have

systematically quantified their adsorption and filtration mechanisms, and still

fewer have characterized the impact of multi-layered structure on depth filter

efficiency. We generated multi-layered and single-layered filter systems using

the same amount of filter media in this analysis. Depth filter layer processing

was modeled after the papermaking method and checked for adsorption and

particle rejection. Using an advanced image technique and colloids and surface

principles, the adsorption and filtration processes behind the output of single

and multi-layered filters were studied in terms of chemical engineering and

internal filter structure.

Figure 6. Gravel Filtration & Multilayer Filtration

Diagram

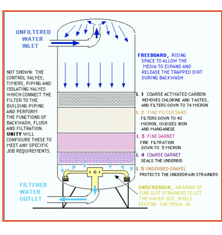

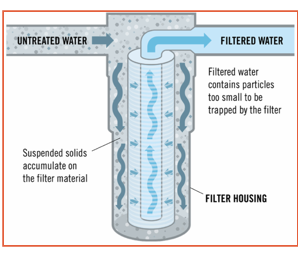

Mechanical filtration

In mechanical filtration, untreated

water passes through a mesh filter or cartridge that traps suspended particles

on the surface or within the filter. Within this type of filtration system,

there lays three most used techniques, which are Cartridge sediment filters,

Single media filters, and Multimedia filters.

The type of

mechanical filtration that will be suitable to your unique situation depends on

the amount and size of suspended solids in the water and the rate at which

water needs to be filtered. For example, a sand media filter has a faster

contaminant removal capacity than other types of filtration devices, but it is

not suitable for the removal of smaller particles. In contrast, cartridge

sediment filters with fiber or ceramic filter materials are made with a smaller

and more uniform pore size and can be more reliable in removing smaller

particles, but they are much slower and need more frequent replacement.

Types of

cartridge sediment filters

There are two basic types of sediment cartridges, depth-type and

pleated-type. Depth-type filters have graded densities with large openings (or

porosities) at the outermost surface of the filter, which decrease in size

toward the center core. These filters trap particles within the filter material

and are usually inexpensive. Pleated-type cartridge filters contain a rigid

polypropylene core for support and are made of one of the following materials:

· Pleated paper – These

filters are the most economical but are not reusable. They are sensitive to

water with low or high pH (less than 6.5 or greater than 8.5). Use them only

when the water contains no active bacteria, which may grow on the cellulose

portion of the filter. Water testing for pH and total coliform and E. colishould be conducted to assess whether your water is

suited for these types of filters.

· Pleated cotton and

polyester – These filters are generally considered the most versatile. They

combine the filtration ability of cotton with the strength of polyester. As long as the water pH is between 4 and 9, they can be

cleaned and reused several times.

· Pleated polyester and

polypropylene – These filters are the most expensive but can be repeatedly

rinsed and reused. However, since the fibers are smoother than the other filter

materials, they are not quite as effective at retaining particles.

Pleated

cartridges have a high filtration surface region, allowing for faster

filtration. The filter collects particles on its outermost surface, causing a

filter cake to form, which improves filtration but delays water movement (or

speed of filtration). They can accommodate huge volumes of particulates and

turbidity without creating a drastic decrease in water pressure. While they are

initially more costly than depth-type cartridges, they are less expensive and

last longer in the long term.

Turbidity

is a measurement of water's relative purity. When a light is shined into a

water sample, it is an expression of the volume of light scattered by the

materials present in the water. The turbidity increases as the amount of

dispersed light increases. Clay, silt, thinly divided inorganic and organic

matter, bacteria, soluble colored organic compounds, and microscopic plants

(not recognizable to the naked eye) and other microscopic species all

contribute to the turbidity of water.

Figure 7. Mechanical Filtration Process

Water pressure forces water through

the media or fiber wraps through the inner cylinder in the sediment filtration

phase, where it is then free to pass through the water line. The medium

contains toxins and dissolved solids from the stream.

The pore space between media fibers

or granules can decide how many particles are kept. These filters come in a number of sizes and meshes, varying from fine to coarse.

The average pore size is reported on most filters, and the vendor scores them

based on the smallest particle they can trap. A 10-micron (one thousandth of a

millimeter) filter, for example, will capture particles with a diameter of 10

microns or greater. When shopping for filters, keep in mind that many are only

rated for particles 20 microns in diameter or larger. Clay (less than 2

microns) and certain silt particles (2.0-50 microns) smaller than 20 microns can not be effectively eliminated by filters with this

rating. They would, though, capture sand particles varying in size from 50

microns to 2 millimeters.

The cleaner the filter, the more

contaminants are trapped, and the filter must be adjusted more often. The

filter can quickly clog if the pore size of the filter material is too tiny, or

if the content of suspended solids in the untreated water is too high, causing

regular replacement. Suspended solids, on the other hand, can move through the

system if the pore size is too big.

When a fresh or replacement

cartridge is fitted, the water pressure into the filter is at its highest. A

filter cake forms when stuck content accumulates in the filter,

and may improve its efficiency by aiding in the filtration phase. Water

flow, on the other hand, would eventually decline as trapped fluid accumulates.

The filter cartridge can be washed or removed until the water flow becomes too

sluggish to use.

Single Filters and Multimedia Filters

Media filters consist of a tank, a

single filter medium, multiple filter layers, a support system, and an

underdrain. The bed depth of the filter medium is usually 24 to 36 inches and is

comprised of silica sand, aluminum silicate, and/or crushed anthracite (a hard,

compact variety of mineral coal). Usually a gravel

support system prevents the medium from being washed out of the device. Media

filters can be cleaned by backflushing and reused. Filters are rated by the

smallest particle sizes they remove. With a same sized tank, multimedia filters

have a greater filtering capacity than a single-media filters. Generally,

multimedia filters also operate at a higher flow rate and require less frequent

maintenance than single-media filters.

Here are some examples of how this filter is used and, one thing

to take notice is that media filters are point-of-entry (POE) devices that

treat water at its entry point into the home. Some common uses of media filters

are:

·

Media

filters remove particles that cause turbidity (cloudiness of water). These

filters can also be part of iron, manganese, and hydrogen sulfide removal after

they have been oxidized into solid particles via aeration, chlorination, ozonation,

or greensand filtration. See UGA Extension Bulletin 939, Circular 858-11, and

Circular 858-15 for explanations of these treatment systems.

·

A

media filter can be used as a prefilter when suspended solids in the source

water could reduce the effectiveness or service life of another primary

treatment device like ultraviolet light or chlorination units used to disinfect

water. If suspended solids are not removed prior to the UV device or

chlorination unit, the solids may shield microorganisms from the killing action

of light or chlorine and result in unsatisfactory treatment performance. See

UGA Extension Bulletin 1487, “Household Water Treatment: Disinfection Methods

and Devices.”

·

Prevention

of sediment build-up in washing machines, dishwashers and hot water heaters

Furthermore, a single media filter

operates by enabling untreated water to reach the filter tank under pressure

from the top and percolate through the medium, trapping any suspended solids.

At a significantly decreased strain, treated water escapes the system from the

bottom of the medium. Suspended solids settle on the media surface, creating a

filter cake, which helps in the filtering of fine particles but decreases water

movement over time. The multimedia filter operates in a similar manner, only

that the various levels of filter media are organized in order, with the

coarsest content at the top and the finest at the bottom. Bituminous

coal/plastic beads and anthracite coal/sand/garnet are two instances of

sequential media layering from the top.

At the bottom of the media bed is a

media support structure (usually gravel) and an underdrain. The media does not

wash through the underdrain because of the gravel support. Under heat, water

reaches the top of the tank and passes across the media layers. Suspended

solids are suspended by lower layers after passing through the top layer.

Multimedia filters, in comparison to single-media filters that capture

suspended particles at the top of the media column, trap particles throughout

the depth of the web. Multimedia filters, on the other hand, need less regular

maintenance than single-media filters. The interparticle pore space, which

specifies the size of suspended solid particles in untreated water that will be

filtered out, is defined by the particle size in the different media layers.

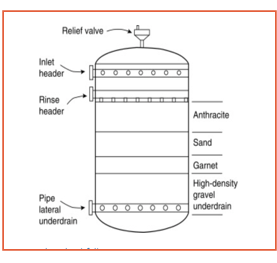

Granular Media filtration

Granular Media Filtration (GMF) is

the process of removing suspended or colloidal particles. For example, to

remove the suspended solids remaining after precipitation. By removing

particles of various sizes (from coarse sediment down to 10.0μm), it can reduce

turbidity and improve clarity. Filtration can protect the IX resin bed and

RO/NF membrane elements from particle contamination. Media filters have

different size exclusion levels, from 10 to 100 μm,

depending on the size of the particles to be removed. Generally, when the water

sludge density index is about 5, suspended and colloidal particles can be

removed by GMF, dead-angle MF and crossflow MF. For high-concentration

colloidal substances, coagulation and flocculation are required before media

filtration.

The granular multimedia filter has

a layered bed of anthracite (0.8-1.2 mm in size), sand (0.5-0.8 mm), garnet

(0.4-0.6 mm) and magnetite (0.3-0.4 mm) or other materials, such as As shown in Figure 2.4. The top

layer of the bed is composed of the lightest and coarsest graded material, such

as anthracite, while the heaviest, finest material, such as garnet or

magnetite, is the bottom layer. The middle layer is silica sand. The specific

gravity of anthracite is one-half of silica sand. The typical bed depth is 1 m.

The principle is "deep filtration"-larger particles are removed in

the top layer, and smaller particles are removed deeper in the filter medium,

that is, the entire bed acts as a filter, instead of the top few centimeters.

Figure 8 :

Granular filter

During use, water usually flows

from the top to the bottom under pressure. The typical service surface flow

rate (velocity/cross-sectional area of bed) for single media gravity and pressure

filters is 7–12 m/h, multimedia media gravity and pressure filters are 14–20

m/h, and 12–24 m/h is used for Upstream filter. The operation of the filter

must avoid channeling and "leakage" of suspended solids. Otherwise,

the reverse osmosis membrane will be soiled. There is a water level above the

bed (freeboard is 50-100%) to expand the bed during backwashing. Since

suspended solids will collect on the medium, regular cleaning (backwashing) is

required. The repelled particles form a layer on the surface of the media and

help to block the pores in the filter media, resulting in an increase in

pressure drop (ΔP). Generally, when ΔP reaches 1 bar, the filter will be

backwashed. During the backwashing process, the water flows in the opposite

direction. It enters the bed from the bottom and flows upward. This fluidizes

the bed and, together with the countercurrent flow, removes the sludge and

takes away the waste material. Depending on the temperature, the typical

backwash flow rate is 24–36 m/h, which is sufficient to expand the media bed by

at least 50%. The backwash cycle lasts 10-15 minutes, followed by a rinsing

cycle in which water is circulated in the downward flow direction for 5-10

minutes.

Second Category:

Filter Types

Filter paper

For good reasons, wire mesh and

wire mesh industrial filtration are commonly used in commercial and

industrial/OEM applications. In some industrial filtration applications, the

goal is to protect downstream components from particulate matter. In other

cases, a wire mesh filter can be used to separate or screen one substance from

another.

Whether your specific industrial

filtration application needs to remove harmful contaminants from fluids or air,

protect expensive process equipment, or just separate one material from

another. Bag dust collectors, cartridge dust collectors and dust filters are

usually made of synthetic media. Many filtration companies can create your

precise size filter and replace stainless steel wire mesh or wire mesh media to

achieve better fluidity and more efficient machine functions.

The flow rate in the sediment

filter and the separator has a large overlap between the sizes. For example, a

1" filter housing has a flow rate of 1-25 GPM, while a 1-1/2" filter

housing has a flow rate of 10-50 GPM. If your flow rate is within this range,

it is best to choose a smaller size to ensure that the centrifugal force is

sufficient to separate the sand from the water. This means that if you want a

flow rate of 20 GPM, a 1-inch filter housing will be more effective.

There are two different styles of elements, filters and

separators. They all work in the same way; the difference is that the separator

allows more sediment to accumulate before it needs to be removed. Our

"Understanding Sediment Filters and Separators" blog describes the

differences in more detail. 1.5 and 2 elements Depending on the size of the

housing, the appearance of the filter may vary. For the 1-inch housing, the

filter between the filter and the separator looks the same, while for the

1-1/2-inch and 2-inch housings, the filter has a shorter screening area and

keeps the filter part at the valve stem at the top, which provides space for

the accumulation of sediment at the bottom. The image shows a filter element on

the left and a separator element on the right for a 1-1/2" or 2"

housing.

Figure 9: Filter and Seperator

element

Mesh

Material

Mesh fabric

is a barrier material made of connected strands. These strands can be made of

fiber, metal or any flexible material. The connection threads of the grid

produce a net-like network with many different uses and applications. Mesh

fabrics can be highly durable, strong and flexible. They are known and are

usually used in the case of liquids, air and fine particles that require

permeability.

The history of mesh fabrics can be traced back to 1888, when a

British textile factory owner introduced the concept of a clean, breathable

material that can withstand temperature changes into the product. Since the

yarn is knitted or woven together and has an open space between the yarn

strands, it is a superior material for clothing and fashion, and has been used

in clothing, wraps, gloves and scarves in the last century in the final

product. When wet or dry, the material has great adhesion (this only means that

the dye will not wipe off). The mesh is also easy to sew.

There are two main types of mesh materials, polyester and

stainless steel. The polyester mesh is made of non-corrosive materials and has

UV stability/weather resistance. The stainless-steel mesh is made of 316

stainless steel, which is non-corrosive and durable.

Stainless steel will better absorb sharp deposits and particles because they

will not tear the material. In the past, polyester was a more economical

choice, but this changed them and made it a very economical choice. As the

fibers are woven together, they create a very flexible, net-type finish that

has a tremendous range of end-uses. It can be used in so many industries,

including: the food industry; wastewater industry (separating waste and sludge

from water); hygiene and sanitary industry; pharmaceutical industry; the

medical industry (supporting internal organs and tissues); paper industry; and

the transportation industry.

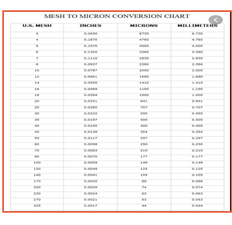

Mesh

Material Sizes

Mesh fabrics can come in many different sizes and are clearly

numbered for understanding. Choosing the required mesh size depends on what

needs to be removed from the water. When talking about filtering, there are

different terms that define the size of the items to be removed. The equivalent

table below shows a comparison between different terms. The equivalence diagram

opening is the size of the space between the water and the material through

which the particles can pass. The number of openings in a square inch screen is

called the mesh size. The micron level is the distance between filter media. A

micron is one-millionth of a meter or one twenty-five thousandth of an inch.

This is described in more detail in "Water Filter-The Basis of Micron

Grade". When using a sediment filter or separator as a pre-filter for

other water filtration products, make sure that the mesh size is equal to the

larger micron level.

Figure 10: Equivalence Diagram

For example, a 4-mesh screen means

that there are 4 "squares" on a linear inch of the screen. A 100-mesh

screen only means that there are 100 openings on a linear inch, and so on. To

determine the grid size, count the number of rows of grid squares in one inch

of linear space measured. This will provide the grid size, which is the number

of openings per inch. Sometimes, the grid size may be refined to 18×16, which

is defined as 18 holes per 1 inch square and 16 rows of openings down. However,

the particle size of a mesh fabric is an indication of the size of the material

that can penetrate and pass through the mesh. For example, the particles

contained in a 6-mesh powder can pass through a 6-mesh sieve.

Third Category:

Coolant Types

Coolants are an

instrumental section of machining, together with grinding, milling, and

turning. They assist lengthening the devices lifestyles and grant a better

finish to machined components. Understanding the function and sorts of coolant

will assist you to pick out a coolant that is the proper for your machine and

operation. By exactly keeping the awareness degrees of your coolant, you

lengthen now not solely the lifestyles of the coolant however additionally your

equipment and machine.

These following

points are the things that the coolant helps provide.

·

Reducing and removing the heat build-up in the cutting zone and

workpiece

·

Provides lubrication to reduce friction between the tool and

removal of the chips

·

Flushes away chips and small abrasive particles from the work

area

·

Protects against corrosion

According to, https://www.firetrace.com/fire-protection-blog/importance-of-coolants

Furthermore, coolants are classified into four

groups and come in a number of formulations. Coolant

should be chosen based on its overall efficiency, which again should be

tailored to your machining application and materials. Here are the following

groups.

· Soluble Oils:

The most widely used of all water-soluble cutting

fluids, and an excellent option for general machining. The disadvantage is that

if the coolant sump is not properly maintained, they are susceptible to fungus

and bacteria microbiological growth.

· Synthetic Fluids:

Since they contain no mineral oil and refuse tramp

oil, these fluids are the cleanest of all cutting fluids. They do, however,

have the least amount of lubrication.

· Semi-synthetic Fluids:

They are thought to be the best of both worlds

because they contain less oil than emulsion-based fluids, have a less pungent

odor, and have many of the same lubricating properties. As a result, they can

be used for a wider variety of machining.

· Straight Oils:

These are non-water miscible and contain

lubricants such as vegetable oils, fats, and esters, as well as a mineral or

petroleum oil foundation. They provide the best lubrication but have the worst

cooling properties.

How Machine Coolant Systems Work

The coolant mixture

floods the work area during the machining process. Chips and particles are also

washed away from the work area during this operation. A sump at the bottom of

the unit absorbs the coolant. The coolant is recirculated to the work area

after being pumped out of the sump.

Coolant systems, both

central and single unit, must be tracked, maintained, and modified. Small

coolant systems, on the other hand, prefer to use less efficient filtration and

oil separation equipment than central systems. Smaller structures are often

more vulnerable to sudden changes in concretion levels and greater

fluctuations. As a result, small-system coolants must be more resistant to

contamination from metal shavings, tramp oils, and other materials. Not only

does coolant form play a role in extending coolant life, but proper coolant

management is even more important.

Coolant Concentration

Several issues will

arise if proper coolant concentration levels are not maintained. Low concentration

is the most common issue. If the coolant concentration falls below the minimum

ratio set by the machine coolant supplier, there is a chance of:

·

Machine and workpiece corrosion

·

Reduction in tool life

·

Bacterial growth

On the other hand, if the coolant concentration is

too high, it causes:

·

Lesser heat transfer

·

Foaming

·

Reduced lubrication

·

Wasted concentrate

·

Formation of residue that shortens tool life

·

Staining of machine and machined parts

·

Toxicity (skin irritation)

The coolant should be

tested at the start of each day to ensure that it is at an appropriate

concentration level. Hand refractometers are an excellent way to keep track of

cutting and grinding fluid concentrations on a regular basis. Evaporation,

splashing, misting, and drag out can cause machine coolant concentrations to

fluctuate by 5% to 20% per day. Keeping a daily log of concentration levels for

each unit allows you to see how the device works and how much concentration

levels fluctuate from day to day.

So again,

you will prolong the life of the coolant, the equipment, and the machine by

choosing the correct coolant for the type of machine and the metals being

machined, as well as preserving the concentration levels.

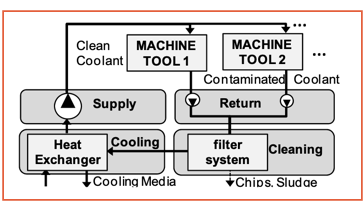

Fourth Category:

Control Systems

Energy efficiency in

industry is becoming increasingly important as energy prices rise and the value

of climate security grows. According to research conducted by Robert Bosch

GmbH, the coolant consumes on average 50% of the electrical energy used in

traditional metal cutting applications. As a result, the focus of this study is

on lowering the energy consumption of the coolant supply system.

Cooling, lubricating, flushing, and transporting

are the primary functions of the coolant. In a circulatory system, the coolant

is used and processed. The following functional units can be found in this

circuit: supply, return, washing, and cooling (Figure 11). After usage in the

machine tool, the contaminated coolant is returned to the cleaning device. In a

filter system, the pollution is isolated from the coolant, restoring the

necessary fluid cleanness rating. In addition, heat exchangers in a cooling

unit keep the coolant temperature stable. There are two types of circulation

systems: centralized and decentralized. Centralized systems are commonly

favored because they are more cost effective than decentralized systems.

Figure 11. Functional units of a coolant

supply system

Various steps to

improve the energy efficiency of the coolant supply system have been developed

in recent years. A previous study conducted at Robert Bosch GmbH aimed to find

additional energy-saving potentials in state-of-the-art coolant facilities. As a

result, the energy efficiency of a number of

centralized coolant supply systems was assessed. Pumps are responsible for the majority of the energy used in the coolant system. Until

now, the primary focus in facility planning and service has been on low acquisition

costs and high plant availability, with energy efficiency being overlooked. As

a result, simple pump solutions, such as bypass-control pumps, are often used

in the design of pumps. These straightforward solutions all have one thing in

common: the pumps run at a constant pace and are unable to adjust to changing

demand. As a result of the availability of different machine tools and ongoing

production changes, the coolant demand in the centralized supply system varies,

resulting in low energy efficiency. As a result, demand-based pump control,

such as variable speed or level control, is appropriate in the supply system

and has become standard in most functional units. According to the findings,

there is still a significant amount of energy savings potential in most forms

of filter systems with pressure filters. The filter pumps are operated at a

constant rpm, and the filter system operates at a high power

level indefinitely, regardless of the need for cleaning. Due to the operating

mechanism of the filters, a pump control is not easily enforced. This paper

uses the example of precoat filter systems to evaluate the energy-saving

potential and to present a framework for demand-based control. Precoat filters

are widely used in fine machining processes to clean the coolant.

Evaluation of the Energy Efficiency

The criteria for high

plant availability and low acquisition costs were met due to the easy operating

mode and relatively low plant complexity. The plants, on the other hand, are

run inefficiently in terms of energy efficiency. The filter system runs

continuously, with all filters operating independently of the amount of coolant

needed. Each filter's filter pump operates at a constant speed. As a result,

the minimum flow rate must be calculated based on the overall coolant demand

needed in the manufacturing process. However, the average demand for coolant in

manufacturing is much lower than the maximum demand. Even with maximum filter

pollution, the pump's throttle is balanced such that the minimum flow rate is

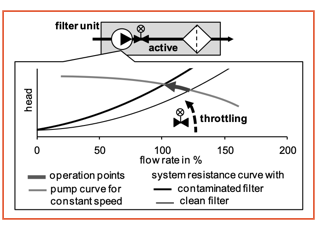

retained (see Figure 12). Because of the pump's characteristic, a lower filter

pollution results in a higher flow rate than required. Furthermore, the

throttle's pressure loss increases quadratically with the flow rate. As a consequence of the high flow rate, there is a high

demand for pump pressure. The inefficient operation is caused by both the

excessive flow rate and the excessive pump pressure. Furthermore, up to 80% of

the pump's output is dissipated as heat into the coolant. As a result of the

excessive heat input from the inefficient pump operation, more cooling power is

required to maintain the coolant temperature.

Figure 12. Pump operation with constant

speed

Concept of a Demand Based Operation

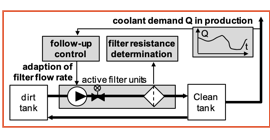

The basic strategy is to adjust the cleaning output depending on

the coolant demand in the manufacturing process, with a follow-up monitor. The

procedure is depicted in (Figure 13.) It is made up of two parts: the follow-up

control and the filter resistance determination process.

Figure 13. Approach for a demand-based

operation

Follow-up control

The flow rate in the filter system's cleaning loop is

continuously adjusted with a follow-up control dependent on the actual coolant

demand in output. A frequency converter adjusts the throughput of each filter

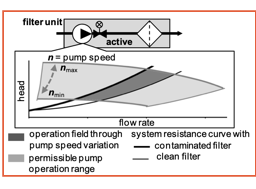

using speed-controlled filter pumps. As a result, the pump speed and, as a

result, the pump output are continuously adjusted to

the appropriate flow rate and pump pressure (Figure 14).

It should be noted that in filter systems with multiple active

filters, it is also possible to switch off a filter when the coolant demand is

low. However, since the flow keeps the filter cake on the filter components,

the filter can only be removed by backflushing. As a result, the cost of a new

precoating filter aid must be weighed. The key opportunity to achieve an energy

and resource efficient operation is to continuously adapt the flow through each

filter.

Filter Resistance Determination

With the change in filter flow rate, a new filter resistance

determination technique is needed to start the cleaning processes. Filter

cleaning in existing facilities occurs after hitting a given cleaning

intensity. This is possible because there is a clear interaction between the

filter pressure and the filter resistance while the pump speed is constant

(operation point curve in Figure 12). For the same filter resistance, the flow

rate, and thus the flow-dependent filter pressure, varies as the pump speed

changes (operation field in Figure 14). With a lower flow rate, the filter

pressure drops, and the cleaning process isn't activated at the right time. As

a result, the filter pressure can no longer be used as a criterion for filter

cleaning.

Figure 14. Pump operation with variable

speed control

Modernizations of existing filter

systems are more popular than the construction of new facilities, since

centralized filter systems are part of the service area and have been in use

for more than 20 years. As a result, a retrofit solution based on the proposed

method for existing filter systems is critical. To calculate the payback duration

of a retrofit, the energy savings must be analyzed. So, in the following

section, we'll go over how to model the filter unit, as simulations are needed

to assess the energy-saving potential of various options as well as the control

behavior. After that, the follow-up control's comprehensive architecture is

presented and tested in a simulation scenario.

COMPETITIVE PRODUCTS

Industrial filter systems are

widely used by industries and companies in order to allow for industrial

operations to flow smoothly and be more efficient. There are various types of

filter systems as to which are classified and categorized based on the

industries in which the filter system is applied, the process and method of

filtration, and the material of the filters. In addition, many filter systems

are customized to meet the needs of the user based on the machinery in which

the filter system is being made for. As mentioned, there is an unlimited number

of manufacturers and companies that are known for their filter systems.

However, only four companies that produce filter systems have been taken into

consideration for comparison since they are the closest competitors to the Resy Filter Systems. The competitive products are defined

and listed below. There are more

competitors but only the following would be used for comparison, the rest can

be found in the Appendix of competitors.

|

Examples

of Competitive Products |

|

Shelco Filters- https://shelco.com/products/shelco-industrial-products/ |

|

Tekleen filters for industry and

Irrigation- https://www.tekleen.com |

|

Forsta filters for industrial,

irrigation and municipal applications- https://www.forstafilters.com |

|

Compacto Compact Band filter- https://www.u-techindia.com/product/compact-band-filter/ |

Shelco Filters

Shelco Filters is

one of the many leading industrial filter manufacturers in the United States

since 1973. They design high-quality filters to improve performance at a lower

cost. Shelter Filter Cartiidges are applied in

various high-purity applications such as in petrochemicals, photographic

solutions, pharmaceuticals, cosmetics, and many others. Additionally, Shelco range of industrial filter cartridges are customized

to meet the needs of the customer by the wide range of cartridges such as

stainless steel and carbon block cartridges. In terms of customization, Shelco works with customers to ensure that the right

designed filter cartridge material is used as well as offering the different

design options ranging from duplexing and multiple fittings.

Figure 15: Shelter Filter Cartridges

One of the most common filter

cartridges manufactured by Shelco is the Microsentry SS Series- Stainless Steel Filter Cartridge.

This type of filter cartridge is designed for extreme high temperature

applications greater than 500 degrees Fahrenheit and differential pressures up

to 60 PSID. In this way, the filter cartridge is either made up of 304L or 316L

stainless steel filter media that is used to provide maximum strength. Based on

the design specifications, the filter cartridge can be cylindrical or pressed

filter configurations in order to offer more lasting results as well as allow

for a greater dirt holding capacity.

Tekleen

Filters for Industry and Irrigation

Tekleen water

filters is the industry’s highest quality automatic, self-cleaning water

filters and strainers. These filters are designed for industrial water filters

and irrigation filters. Tekleen Automatic filters has

manufactured over 25,000 filters worldwide and providing filters to over 500

companies. Tekleen water filters are offered for

various applications such HVAC, petrochemical, sea water filtration, power

generation, and even oil production.

Figure 16: Tekleen

Water Filters

Tekleen water

filters are applied in metal processing. The way these filters' function is by

circulating the water through hot wells, cold wells, and cooling towers to cool

the jacket molds and metal products.

While the operations circulate the water, the dirt particles begin to

enter the system while reducing the heat exchangers function as well as clog

the spray nozzles. This affects the consistency of the metal and the finished

product. However, the finished product may experience many complications such

as metal spotting or break-out. Tekleen works to

self-clean the water filters reducing such complications that may be

experienced while metal processing. These self-cleaning water filters operate

on pressure and are very compact in size making it easier to install.

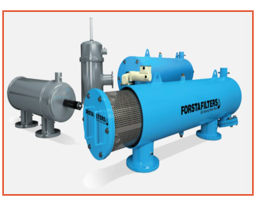

Forsta Filters

for Industrial, Irrigation and Municipal Applications

Forsta Filters

are automatic self-cleaning water filters that are based on producing less

wastewater while also being more cost effective. These filters are also

designed to function on their own without causing any disruptions to the rest

of the system during the cleaning cycle. In addition, Forsta

filters are low maintenance and provide a high efficiency. These filters are

applied to various industries such as industrial and irrigation. Based on the

industry and application, these filters are customized to specifically meet the

need of the consumer. In this way, these filters range in sizes, orientations,

and degrees of filtrations all in order to accommodate to the application.

Furthermore, Forsta

self-cleaning filters are used to remove particles from the different water

sources. Such particles include but are not limited to pollen, dust, metal

shavings, pipe scale, marine organisms, and fibers. These filters can be

applied to different water sources such as in a reservoir or in wastewater.

Figure 17: Forsta Filters

Compact Band Filter

Compact Band Filters are

manufactured and designed by U-Tech. These types of filters are utilized in

contaminated coolants that are part of Computerized Numerical Control (CNC)

machines. U-Tech Compact Band Filters are designed to offer better filtration

and efficiency in comparison to other types of filters. The way that these filters function is based on reducing the amount of filter

paper used as well as a decrease in the motor power consumption. That is why

this company states and offers a very high degree of reliability of their

product and guarantees that the Compact Band Filter will reduce the amount of

paper filter and motor power.

The Compact Band Filter has many specified features that allow

it to be distinct and more efficient compared to other filters. This filter is

very compact in the way that it will occupy less space meaning that it only

makes up of one third of conventional paper band filter. As mentioned before,

the design of the filter allows for less consumption of paper allowing for

paper to last much longer. In this way, the paper filters wouldn’t have to be

changed constantly due to the paper lasting much longer than usual filters.

This also saves up on having to buy so many paper filters for the machine. In

addition, the Compact Band Filter can be used to filter coolant and oil with

ferrous and non-ferrous metal and non-metals. Most filters do not function or

are not as efficient when it comes to filtering metal shaving or dust. This

type of filter does in fact ensure that the surface in which is being filter is

left with no residue of any kind leaving a clean and smooth surface. One of the most important features of this

filter is that is made up of microfiber and paper filters that come in various

sizes in order to meet the needs of the consumer.

Figure 18: Compact Band Filter

All in all, the competitive products that were taken into

comparison are shown to have similar and distinct qualities when compared to

the Resy Filter System. Most of the competitive

product's function in filtering a system by removing certain particles leaving

a smooth and clean surface. It was noted that out of the four competitive

products, most of them offer customization for the user. What this means is

that users are able to request how they prefer or

would like their product to be. This is mainly based on the

fact that most filters have to be redesigned to fit in certain

machinery. These are similar qualities seen in the Resy

Filter System which why these products have been selected as competitive

products to compare and note that the Resy Filter

System is the better option when compared to these products.

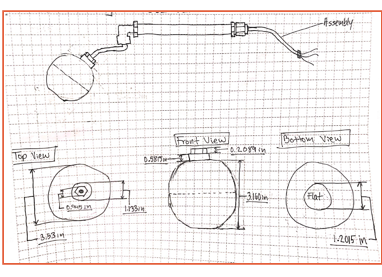

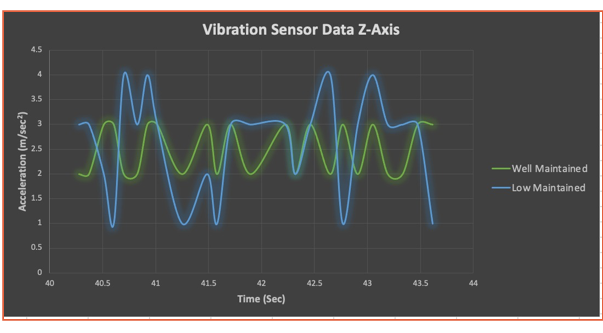

Float level sensor

Water level sensors detect the presence of a liquid in a variety

of ways and use the information to denote its level. For most of us, the

“float” style sensor is the first that comes to mind. A good example is the

float valve in a toilet tank. In the case of the toilet, a float connected to a

lever manually opens a valve to start the flow of water as the tank empties,

then closes it until the appropriate volume is reached for the next flush.

While direct mechanical control is an alternative, in industrial applications,

a small float's movement is commonly used to trigger a switch that sends an

electrical signal to an indicator or a solenoid valve to control liquid flow.

Float switches are the name for these machines.

Figure 19: Lever Float Switch

Float switches are simple,

cost-effective, and suitable for a wide variety of applications. They are not

susceptible to the conductivity, temperature, or precise gravity of the liquid

they are detecting, unlike certain other types of liquid level sensors, and can

be constructed from a range of materials to be compliant with most liquids.

They are especially "user friendly" since they are quick to grasp,

troubleshoot, and replace. The most popular instrument for detecting liquid

level is the float valve.

They are not, though, the only

solution to all liquid level sensing problems. Float switches are susceptible

to wear and a range of mechanical failure modes when they have moving

components. When used for plain water, for example, a well-designed float valve

can be dependable. However, if the water contains chemicals that may cause a residue

on the sensor's working components over time, the sensor's durability is called

into question. They have the opportunity to get

“stuck.” This is particularly problematic when a float valve that detects a

high level is constantly wet and dry, causing deposits to accumulate and

solidify, forming a crusty residue. Contamination of particles is also a

problem. Chips and even clumps of magnetic particles may be drawn to the

magnets and block the reed switch's magnetic activation. The magnetic switch is

often replaced by a different kind of switch that detects the angle of the

float by using mercury to bridge contacts in a sealed tube when a certain angle

is reached. However, making reliable communication to the shifting switch

housed in the float, which would, of course, travel up and down, is an issue

with this method. Because of their sensitivity to mechanical injury, it is

recommended that float style level sensors be covered with a small cage or

baffle.

A sealed housing containing an

angle sensitive switch, similar to the mercury switch

mentioned above, is one version of the float switch. The sensor is tethered in

the vessel in this situation so that it floats on its side on the liquid

surface before the critical liquid level is reached. When this occurs, the

tether pulls the sensor to an upright position, which triggers the switch. This

kind of float turn is commonly used in liquid storage tanks.

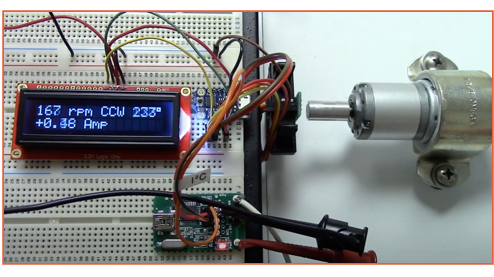

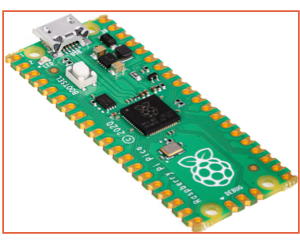

Microcontroller

A microcontroller (MCU for

microcontroller unit) is a miniature device built on a single MOS integrated

circuit (IC) chip. A microcontroller is a computer that includes one or more

CPUs (processor cores), memory, and programmable input/output peripherals. A

limited amount of RAM, as well as program memory in the form of ferroelectric

RAM, NOR flash, or OTP ROM, is often used on chip. Microcontrollers, in

comparison to the microprocessors used in personal computers and other

general-purpose devices, are designed for embedded applications and comprise of

a variety of distinct chips.

A microcontroller is like, but less

complex than, a device on a chip in modern terms (SoC). A microcontroller may

be one of the components of a SoC, but it is typically paired with specialized

peripherals such as a graphics processing unit (GPU), a Wi-Fi board, or one or

more coprocessors.

Microcontrollers are used in

products and applications that are remotely controlled, such as car engine

control systems, implantable medical devices, remote controls, office

machinery, appliances, power tools, toys, and other embedded systems.

Microcontrollers make it cost-effective to remotely monitor many more machines

and processes by reducing the size and cost of a design that uses a separate

microprocessor, memory, and input/output devices. Mixed signal microcontrollers

are widely used to monitor non-digital electronic devices by combining analog

components. Microcontrollers are a cost-effective and widely used way of

collecting data, detecting, and actuating the physical world as edge devices in the internet of things.

For low power consumption, certain

microcontrollers use four-bit words and run at frequencies as low as 4 kHz

(single-digit milliwatts or microwatts). They can maintain functionality when

waiting for a case, such as a button press or other interrupt; power consumption

while sleeping (CPU clock and most peripherals off) can be as low as nanowatts,

making many of them ideally suited for long-term battery applications. Other

microcontrollers can be used in performance-critical applications, requiring

higher clock speeds and power usage than a digital signal processor (DSP).

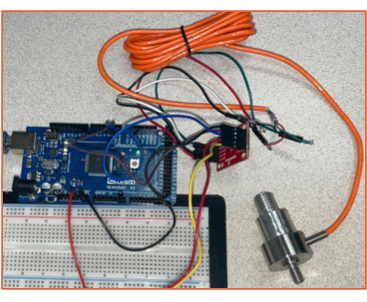

Figure 20: Arduino Microcontroller

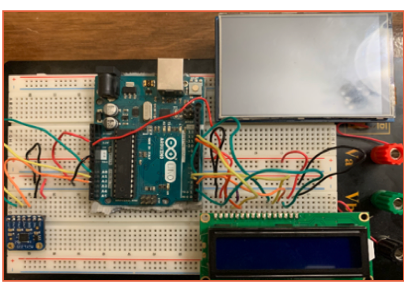

In addition, Fig.## above which is an Arduino is an

open-source tool that can be used to create electronic projects, which will be

considering using in the SD1 project. Furthermore, Arduino is made up of a

physical programmable circuit board (also known as a microcontroller) and

software, known as an IDE (Integrated Development Environment), that runs on

your device and is used to write and upload computer code to the physical

board.

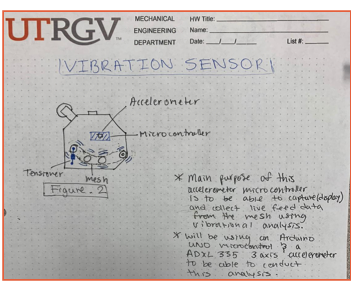

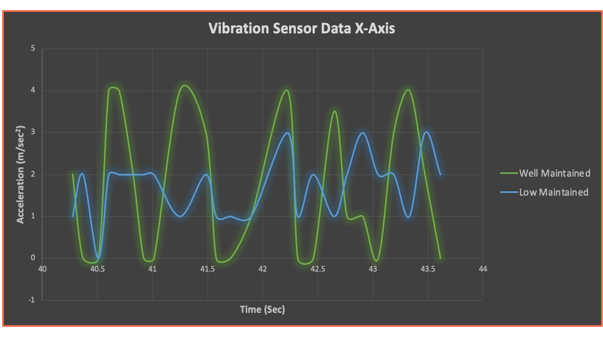

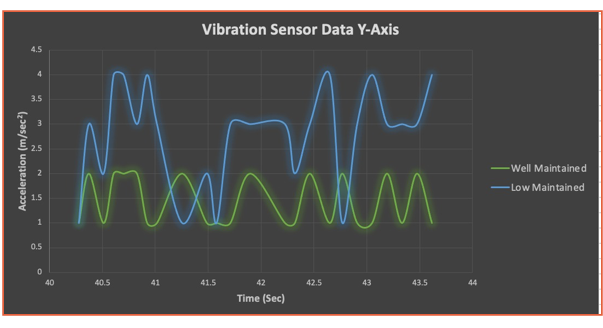

Vibrational Analysis

Reactive maintenance (repairing a

defect as it occurs), which is gradually being phased out due to its high

costs, and proactive maintenance are two common maintenance techniques in

industry today (based on physical inspections at scheduled intervals of time).

Predictive maintenance is one of the most important fields of study for

industrial motors, as well as aircraft, automotive, and marine vehicles, since

it reduces total running costs significantly. It's founded on the fact that a

mechanical component failure is normally followed by a time of gradual and

crescent regression of action and efficiency. These incipient defects may be

detected, and measures taken before they cause significant problems or harm to

other sections of the equipment if enough on-line tracking is used. Monitoring

of security-relevant components and signals is the state of the art and is

mandated by qualification requirements in the case of mechanical components of

a windmill. The use of a fault detection system in this setting is critical

because it has a number of potential benefits,

including the prevention of premature breakdown, lower maintenance costs by

avoiding the replacement of intact parts during preventive maintenance, remote

diagnosis (which is critical because windmills are typically located in remote

locations), and prognosis and ada. Vibration control

is used in the case of spinning devices, such as the mechanical sections of

windmills (bearings, gearboxes, and so on), and fault detection systems analyze

spectral analysis results, such as FFT, Cep-strum, envelope curve analysis, and

so on, to produce diagnosis and even estimates of the piece's remaining

lifespan. The theory behind this is that noises found in all parts of a

mechanical system will detect almost any flaw. The vibration analysis is based

on the changes that occur in a machine's vibrational behavior when a latent

defect is discovered in one of its components. Predictive maintenance of

windmills is currently performed manually or semi-automatically by trained

professionals, rendering it a high-cost operation. For automated diagnosis and

prognosis, many models have been used, several of which employ Artificial

Intelligence techniques. There are very few articles published in the field of

prognosis. The on-line SBLLM (Sensitivity-Based Linear Learning Method), a

prognostic model based on a supervised feedforward on-line learn-ing algorithm for two-layer feedforward neural networks

based on sensitivity analysis, is presented in this article. The algorithm

provides a compelling combination of speed, accuracy, and simplicity, making it

ideal for real-time prediction.

USER RESEARCH

Filtration technology has advanced

throughout the years. There are various types of filtering processes as well as

the type of filter paper or filter material that is used based on the

specifications of the substances used. In this way, there are questions that

could be asked to potential customers to fully understand their specifications

and expectations when it comes to the filtering technology. For instance, there

are various types of filters that are used for different types of materials

such as those used to filter a substance that contains metal shavings or even

dust. Also, the type of machine that the customer uses is very important since

the filters must be designed to fit in the specified machinery. Most

manufactures do provide filter customizations to meet the needs of the

consumer.

Question that would be

asked to potential customers.

1. What type of

filtering process is your company looking for? Ex. Centrifugation, Paper band

filters, etc. And how big of a scale is the operation you have (Machine wise)?

2. What type of metal

cutting machinery do you have?

3. What type of

appropriate coolant filtering process does your machine need to be in safe

operating conditions?

4. How much space, are

you willing to make/or have for the filtering machine?

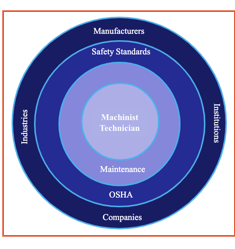

Figure 21: Stakeholder map

It

highly important to understand who the user is and how they may affect other

users. Figure 15 illustrates potential users for filter systems for

industrial machining fluids in a stakeholder map. As it is shown, the user of

the filter system is narrowed down to a machinist technician since they are the

ones who understand and utilize the filtering system machine. Most companies

have a designated person who will utilize the machinery which is known as the

machinist technician. In addition, there are also people who oversee keeping

the machine clean and safe to use which can also be known as maintenance.

Furthermore, the filter system machine is in the hands of the manufacturers.

These manufacturers are responsible in producing the filtering system machine

and distributing it to other companies or customers that have purchased the

product. There will be existing companies as well as new companies that may

want to purchase the product. In addition, there are various industries that

use filtering technology. For this product in particular the industries that

use this product are known. These include but are not limited to the wire and

cable, tooling machine industry, automotive and supplying industry, and the

glass and environmental industry.

Safety

is also something take into consideration. There must be supervision and

inspection of the filtering systems to ensure that they function properly and

are safe to use. There are different organizations such as OSHA that need to

approve that the machinery used is safe to use. The Occupational Safety and

Health Administration should be taken into consideration in the designing of

the product. The product needs to be approved by this organization to ensure

that any material being used will be at no harm to the user. For instance, a

metal used in the product might cause a reaction if a person is in contact with

it leading to a more complicated health issue. If this occurs, the company or

manufacturer may be sued and may be found guilty if this issue occurs amongst

more users. That it is why it highly important to consider the different

materials used in designing of the material and how it may affect the user. In

the case that the safety standards are not met due to any factors such as the

design, the machinery is not allowed to be used or able to be put in the

market. In addition. there are certain standards that are to be followed. While

designing the product, it is highly important to note what the standards are,

and which ones are to be followed. If the product does not comply with the

standards, the product would have to be either redesigned or it wouldn’t be

able to be sold or distributed to the user. There are different handbooks that

include these standards such as the American Society for Testing and Materials.

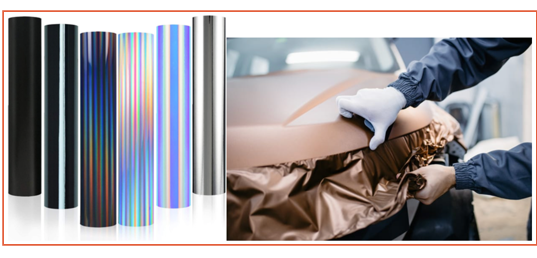

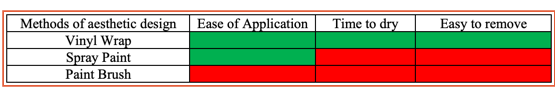

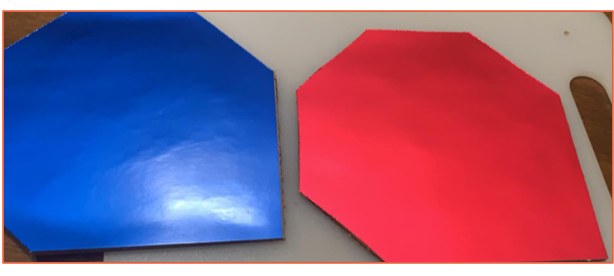

This is an ‘international standards organization that develops and publishes

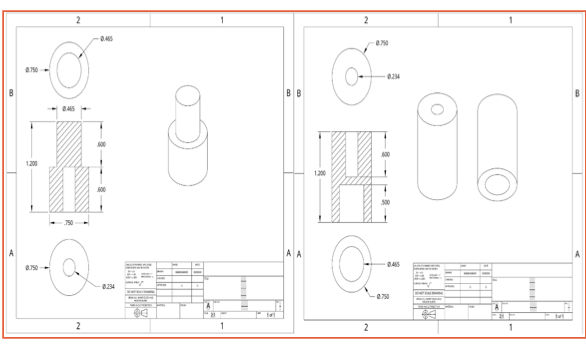

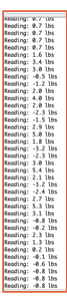

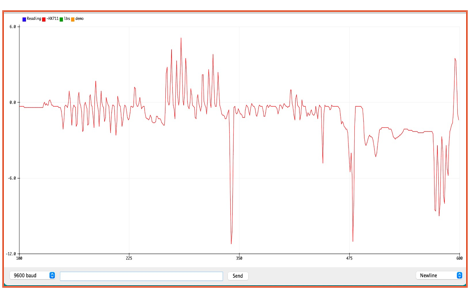

voluntary consensus technical standards for a wide range of materials,