UTRGV / COLLEGE OF ENGINEERING AND COMPUTER SCIENCE / MECHANICAL ENGINEERING DEPARTMENT

TEAM 10: AUV Wave Energy Physical

Simulation

|

SDI

Students (From Left to Right) |

Kathy Garza Cynthia

Contreras Hameem Gorabi Hernán Ramírez |

|

Faculty

Advisor |

Dr. Yingchen

Yang |

|

Course

Instructors |

Dr. Noe Vargas Hernandez Mr. Greg Potter |

Welcome! We are team

#10 “Mech Wolves”, consisting of members Hernan Ramirez, Hameem Gorabi, Cynthia

Contreras, and Kathy Garza, advised by Dr. Yingchen

Yang. Our project (entitled AUV Wave Energy Physical Simulation) tackles the

problem of a lack of available AUV’s with flexible energy generation

capabilities, to which we provide the ‘proof of concept’ viability of wave

energy for AUV’s via a sophisticated physical simulation. We have designed a

device that inexpensively (but physically) replicates the internal motions

involved in wave energy generation via a tank with simulated waves and outputs

an accurate estimation of wave power output that would be received in those

conditions, improving upon the efforts of our predecessor group.

Click on the Welcome

Video below!

This video presents a basic introduction to AUVs and how they

are used. Click here to watch.

AUV’s (Autonomous Underwater Vehicles, sometimes

referred to as UUV’s or Undersea Autonomous Vehicles) require long lasting

energy with minimal top-offs and little to no maintenance for long periods of

time for their underwater missions. Currently this need is provided for via

batteries and occasionally solar, but these are troublesome solutions with a

plethora of necessary tradeoffs and limitations. Wave energy generation

provides power without the need for constant resurfacing or maintenance – and

can do so even from some depth. Brought into a practical design, it may

significantly extend the duration of operation, enabling greater efficacy of the

AUV platform.

A sub-problem of this practical implementation is

the risk-expense of implementing such a system on a prototype – there must be

greater evidence than possibly limited computer simulations that such a system

will output desirable amounts of energy. A physical simulation using a simple

mass-spring-damper setup instead of a full wave energy one can provide a close

simulation of energy output while taking potentially unseen variables into

account, providing a clearer picture of what an actual system will be capable

of, and doing some of the design heavy lifting.

To better understand the AUV market and the ways

in which a wave energy product can contribute to it, we have conducted detailed

research on the topic. Listed here are notable snippets of this research which

helped drive our designs, provided useful general information, or were just

plain interesting.

-

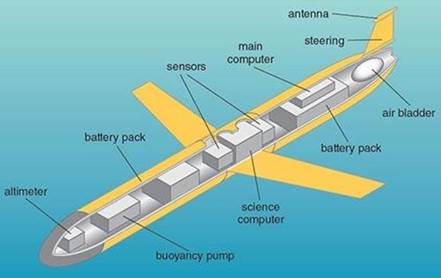

AUV’s have a torpedo-like shape for drag reduction, so internal components need

to cater to this form factor

-

AUV’s are used for research, commercial, military, and exploration purposes

(among others)

-

AUV’s are capable of deep-sea operation, able to operate at up to 6000 meters

below surface level. Some models can go even deeper!

-

AUV battery lifespans can vary from hours to months depending on the battery

source used, but cost scales more than linearly with duration. Two times the

duration means more than two times the price for batteries – a problem energy

generation doesn’t have.

AUV’s are a fast-growing market, expecting up to

a 20.8 percent increase in market size from 2020 to 2027 (Bizwit Research &

Consulting LLP, 2020). They find use in research, exploration, military, salvage,

rescue, ocean floor monitoring and more. Several noteworthy organizations and

institutions including but not limited to those listed as users on our stakeholder

map (shown below) make extensive use of AUV’s, most of which benefit from

improved operational duration – which is what we’re working on with wave

energy.

PROPOSED SOLUTION

“We propose several key improvements on

the design of a novel energy capture mechanism that transforms the natural

ocean wave motion energy into electrical energy for autonomous underwater

vehicle (AUV) extended operations and seek to implement them on physical

simulation platform[nv2] .”

After coming to

understand the problem at some level of depth, we have begun the design process

and come to a proposed solution to work through. To get a brief understanding

of the improvements we aim to implement, click here.

‘Classic’ AUV Design:

Last-Gen Physical Simulation Wave Generation Design (Springs,

though absent, were featured):

Physical Simulation of Wave Generation Design:

Present Physical Simulator Design (3D CAD Model):

[To see this project in progress, check out the ‘Prototype

Early and Often Section’!]

Once our solution

concept became clearly defined, we began applying our engineering knowledge to

‘bring it to life’ so to speak. Listed below are a few of the most significant

challenges in no particular order, accompanied by

descriptions of how we have addressed them.

1. Overall size/weight constraints for

buoyancy

This

is a balancing act that required attention during nearly every step of the

design process, including when facing other challenges. Still, we were able to

settle on a ~4’’ diameter and 25” length (more than a 50% increase from the

last group’s dimensions) in order to provide more space for air and make a more

efficient system with a larger mass while remaining neutrally buoyant.

2. Minimal damper length/size, maximum

damper stroke length

Unfortunately,

no dampers on the market that meet our specifications exist – so we took it

into our own hands and fabricated some ourselves. We’re using lightweight

aluminum partially hollowed out, with emphasis on a larger internal air chamber

and a small air output port hole, to damp sufficiently but keep motion going.

The input/output port will be small air holes, to be drilled larger as needed.

3. Smooth damped oscillation of mass for

ideal energy generation

While the damper has some

bearing on how smoothly the mass will move, it’s not the only notable factor. A

strong rod material, proper alignment, symmetrical mass, minimized deformation

of the system when in motion, surface compatibility, lubrication and more all

contribute to the smoothness of the motion. Once we took care of our damping

concerns this was the next priority.

4. Strong, ocean-safe materials for general

housing (some must be clear to examine the system at work)

There was some initial

conjecture about making the housing clear PVC. It’s cheap, see through, and

seems to do OK with water – the only problem was that it would definitely

deform under some serious motion and that would mess up our precious alignment.

After running through a few more options, our advisor recommended

Polycarbonate. Clear and salt-water compatible like clear PVC, but also strong

and durable – everything we needed it to be. It’s our definitive housing of

choice.

5. Accurate, compact, and non-intrusive

sensor setup

We went for the most

non-intrusive sensor possible – an external one. With a high framerate camera and

moderately high resolution we can observe the oscillating mass behavior with enough

detail to analyze it.

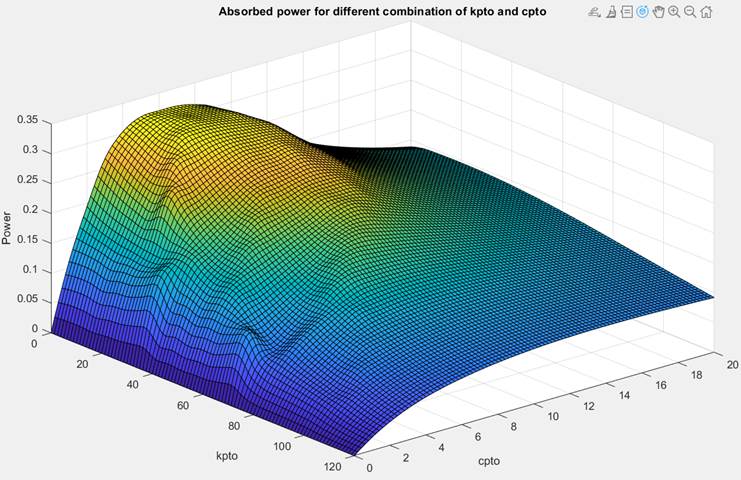

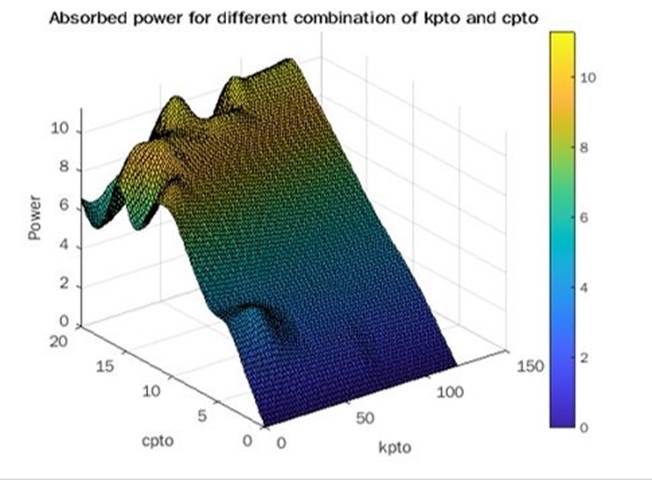

Our design specifications were

influenced by the predecessor product and existing analysis of its optimal

power output based off a modeling of the ‘system’ (provided by Mahmoudul Maheen, a graduate

student who works on AUV research with Dr. Yang, and us by extension). The

theoretical power output of the predecessor system is quite small due to the lower

scale of the previous prototype. The design decision to increase scale was to

simplify fabrication and increase system efficiency, but also to make it

simpler to bring to working order, which the previous group had a lot of

trouble with. The size of the mass (the analogue to the magnet in the magnetic

coil generator we’re simulating) corresponds strongly to the simulated output –

the larger the mass, the larger the output. More importantly, the greater the portion

of the overall assembly goes to the mass, the more efficient the system is –

the ‘mass budgeting’ required for buoyancy has less relative cost as certain

components (like the outer tube or guiding rod) do not need to be scaled up as

much to maintain efficacy. On the left is calculated watts power generated

based on prospective kpto (system spring constant,

N/m) and cpto (system damping constant, Ns/m) for the

predecessor system, and on the right is the same modeled calculation but

updated to reflect the changes made in our system. For reference, the prior

maximum theoretical wattage was less than a single watt and the new maximum

theoretical wattage is a little over 11 watts.

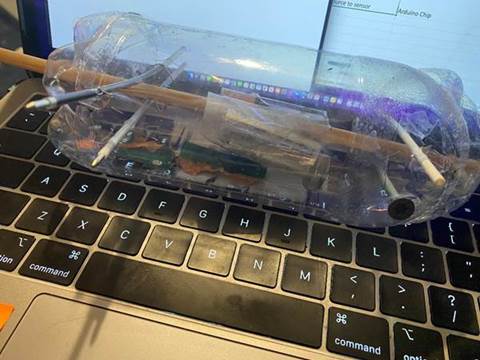

Physical prototyping using available

materials can quickly bring a design to life without needing all the labor and

detail-work for a full functioning product. Using our prototypes, we were able

to identify flaws and other attributes we simply missed while constructing them

mentally. A few of these rapid ‘junkyard’ prototypes are shown below, with

explanatory subtitles.

In the above prototype, an

oscillating battery would be used instead of some portion of the mass. The idea

is that it can power some of the internal systems until wave power kicks in

without serving as dead weight. Observing this rapid prototype made us realize

that the wiring would be a mess for a moving battery meant to power a sensor or

some aux systems – and would detract from energy generation in a non-simulation

design.

This

prototype is much closer to what we want to build. The mass is aligned with the

rod, the springs configured where the spring-dampers would be, and the housing

roughly similar to what we have in mind. It does lack endcaps – an issue we

will need to consider.

Here is

an advanced ‘junk yard’ prototype – it closely resembles what we wish to build.

In place of air-sealing damping chambers, there are small springs in the inner

tubes. A block of wood with an attached wooden rod represents our mass and rod

configuration, and the tube itself is close to our expected form factor. The

cut-away section is for demonstration purposes – our final build will be

watertight.

PROTOTYPE DEVELOPMENT

----

The details below describe the work and progress of the final prototype----

Throughout

the course of three summer months, we gathered the materials we ordered or

needed and had blueprints for the manufacturing of each part to begin the manufacturing

process. The following is the work done in the summer of 2022 and the following

months:

Damper Base:

·

Aluminum 6061 4” disc

·

2 damper bases

·

Lathe and CNC for manufacturing

The damper bases are used for the placing and the alignment

of the rod through the prototype.

Manufacturing:

·

Easily the most difficult to manufacture of all

parts – greatest complexity and trickiest features.

·

Ultimately produced by making the basic shape on

the lathe, CNC milling the curved slots, and using a manual mill to implement

the back and side holes.

·

Port for air drilled using a micro-chuck and fine

drill to start with, gradually going up in diameter.

Damper Tube:

·

Aluminum 6061 round tube

·

2 damper tubes

·

Lathe machine

The damper tube is used to connect to the damper bases where

it holds the rod into place.

Manufacturing:

·

Made from a piece of aluminum tube stock – none

came at the specified thickness we required, so we had to hollow it out more

ourselves, which was tricky because of the limited reach of the lathe tooling

and the necessity of good alignment/straightness.

·

The hollowing out was done with tooling welded to

a steel cylinder and block for extra reach and produced on the lathe (shown

below next to the manufacturing clips). The notches at the end were done with a

manual mill.

Polycarbonate Tube:

·

Polycarbonate tube

·

1 polycarbonate tube

·

Saw, sander, and drill

The polycarbonate tube holds the majority of our materials

together due to the high impact resistance.

Manufacturing:

·

The tube ends required facing after being cut to

size to maintain alignment for initial design.

·

The spring pin holes also required precise

placement and alignment.

·

Extra care had to be taken during both these

processes to not warp or bend the piece, to maintain straightness and

concentricity to a small tolerance.

Mass:

·

Low carbon steel disc

·

1 mass

·

Lathe and Mill machine

Mass is the most important part for our prototype’s purpose.

It can show us how much energy can be simulated with the motion due to the

waves.

Manufacturing:

·

The mass of this piece plays a central role, so

avoiding excess material removal was a priority, more so than with other parts.

·

Manufactured mostly with a lathe, with the mill

being used to install the holes.

Rod:

·

Aluminum 6061

·

1 Rod tube

·

Lathe machine and drill

The rod is used to hold the mass

and it moves freely through the damper tubes.

Manufacturing:

·

Mostly produced with a lathe, the hole being

drilled with a mill.

·

Required additional support on the lathe due to its

long length (pictured below partway through production).

Caps:

·

Aluminum 6061 sheet

·

2 end caps

·

Mill machine and drill

The caps are designed to be used to enclose the polycarbonate

tube from water entering the tube by pressing a rubber O-ring into place.

Manufacturing:

·

Round edges produced on lathe; holes drilled on

mill.

·

Had to be produced carefully because of very

small grip area.

The Advanced (Close to Final) Prototype:

·

Assembly of parts described above, with some

changes as required

·

Design concerns at the point of this assembly:

waterproofing and smooth motion

·

Recent addition of springs for the latter concern

Quite close to our final research product, has been

troubleshooted until operational since then.

Revisions:

Since this is an Engineering project, things didn’t go fully

to plan. The pressure the endcaps exert on the O-rings to seal the assembly

work – but only insofar as they prevent water from entering, as they mess up

alignment. We were somewhat prepared for this potential outcome – the endcaps

were relatively small and not used to anchor the assembly to the polycarbonate

tube, designed with the knowledge in mind that they may not work as they should

in theory.

·

A few options had already been ruled out earlier

in the design process, when considering waterproofing and the need for

disassembly/reassembly.

·

A low-pressure seal using ‘waterproof’ sealant

tape was an option – no practical way to model it, so we tested it out:

·

Good, but in this quantity and arranged over a

tube it wouldn’t last. Follow up idea from a technical consultation: produce an

ideal area to seal off the assembly with an ‘over-the-top’ rather than inner

endcap. Weight restrictions and the nature of its larger size meant it couldn’t

be metal.

·

The need for a custom shape and size meant 3D

Printing was a good fit for fabrication. Our instructor, Mr. Gregory Potter,

introduced us to the skills and material selection necessary.

·

After some fiddling with the size and

specifications, an endcap set was produced!

·

And it didn’t work. There was nothing wrong with

the design or the printer – a reprint with a higher quality brand of the same

material, TPU, produced an endcap that did work, bringing us to our final

prototype with which we are conducting tests with:

·

Additionally, springs were installed to

facilitate smooth motion – they do not alter how we fundamentally analyze

damping of motion as an electrical generation analogue because they add no

energy, they merely redistribute it in the service of better motion.

Our

final output is a research-oriented product and shaped up looking a little

different to the CAD design shown in ‘Proposed Solution’. Put under a wave or

wave-like motion, it now smoothly oscillate its inner mass – damping some of

the motion in the process. This damping is a physical simulation of a

conversion to electrical energy – the amount of motion that gets converted.

It’ll allow us to calibrate and troubleshoot the system without the huge

spending or lengthy fabrication that the same process would require on a full

generation prototype (or series of prototypes). We’ve begun the testing of our

prototype using a rotor-motor and a large water tank with simulated ocean wave

motion (the ‘wave tank’ for brevity), shown below.

Here

the rotor motor shows the full range of mass movement – our goal is to get as

much of this range in practice with the wave tank as we can.

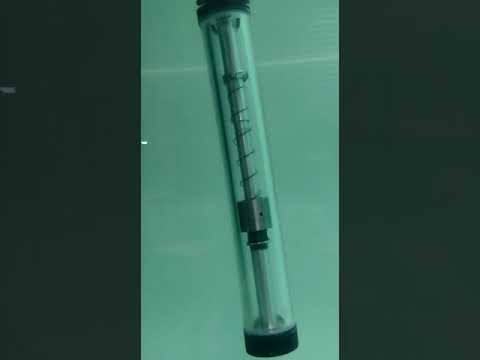

We’ve

begun testing a range of controlled conditions using the wave tank, so we can

see how wave frequency and port size affect the prototype (and the relations

with our theoretical analyses). Here are some clips of the final prototype in

motion during tests for 1/8” at 0.5 Hz (left) and 5/32” at 0.7 Hz (right).

These are just two of them – there are many, many more we’ll be using for

post-testing analysis.

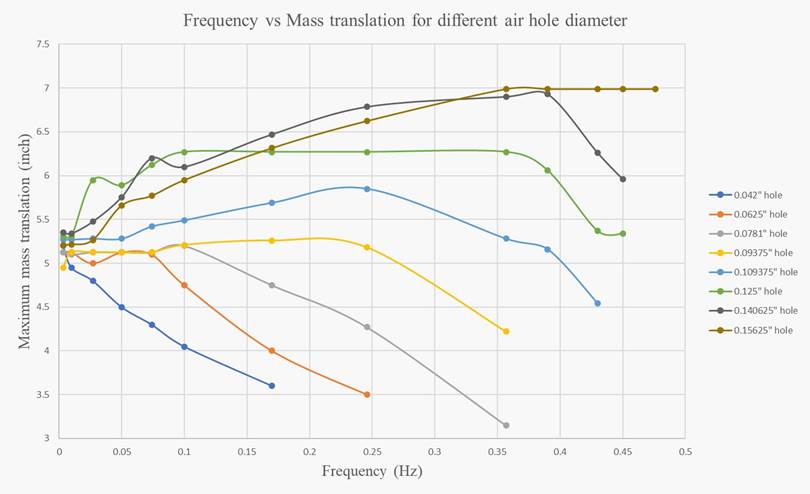

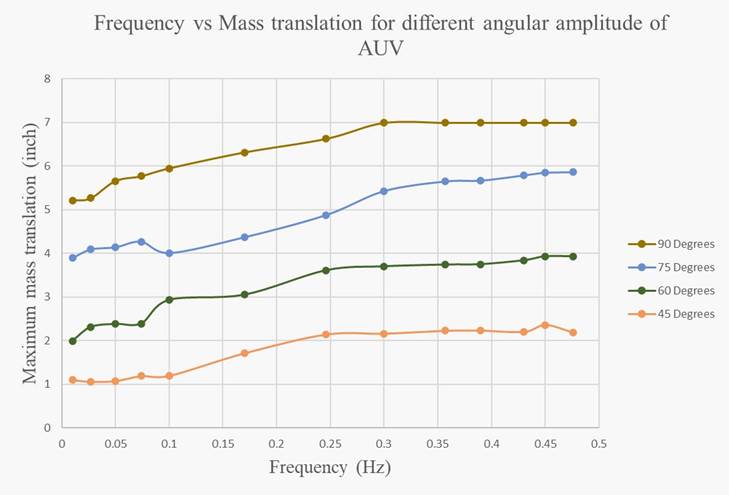

The

testing we’ve accomplished so far has been focused on the variables of frequency,

maximum mass translation, amplitude, and hole diameter. A few relationships

between variables emerge, like the maximum translation of the mass dropping off

for most hole size configurations after a point of frequency (seemingly

specific to the diameter of the hole) or differences in angular amplitude

affecting the magnitude of mass translation strongly but the way it relates to

frequency weakly. Translation is an important value for calculating how

effectively and how efficiently the simulated capture of energy is going.

Future work involves

using calibration data to further refine physical simulators and

simulations, cumulating in the production of a wave electric

generation system using coils and a magnetic unit, with large swaths of the

system already calibrated and troubleshooted. Among further calibration

concerns include size calibration - evaluating several scale

variations for their viability in the AUV's that support their

form factor, and if proportionate scale variation affects system properties in

notable ways. Additional concerns

include the study of system function under variable

conditions, chiefly concerned with weather or ocean conditions

that affect wave motion properties. In the more immediate future, more testing

needs to be done with the present prototype so that a better baseline dataset

can be established.

IN CONCLUSION

Our Senior Design project has contributed to the advance of ocean wave energy generation in a compact AUV platform, using our predecessor’s designs to improve our own and giving our work forward for our successor’s project, and AUV wave generation research beyond. We have successfully manufactured and tested a functional research prototype and begun the collection of data by the time of project completion. Senior Design I&II and the crucial lessons learned by our group in design ideation, refinement, and fabrication, and more has served us well in our project endeavors and will do so far beyond it.

REFERENCES

Bizwit Research & Consulting LLP, 2022. Global

Autonomous Underwater Vehicle (AUV) Market Size study with COVID-19 Impact, by

Type (Shallow AUVs (up to 100 meters), Medium AUVs (up to 1,000 meters) and

Large AUVs (more than 1,000 meters)), by Technology (Collision Avoidance,

Communication, Navigation, Propulsion and Imaging), by Payload Type (Camera,

Sensor, Synthetic Aperture Sonars, Echo Sounders, Acoustic Doppler Current

Profilers and Others), by Application (Military & Defense, Oil & Gas,

Environmental Protection & Monitoring, Oceanography, Archeology &

Exploration and Search & Salvage Operations), by Shape (Torpedo, Laminar

Flow Body, Streamlined Rectangular Style and Multi-hull Vehicle) and Regional

Forecasts 2020-2027. [online] Available at:

<https://www.marketstudyreport.com/reports/global-autonomous-underwater-vehicle-auv-market-size-research?utm_source=marketwatch.com&utm_medium=SHR&utm_campaign=marketwatch>

[Accessed 22 February 2022].

Team 10 Mech Wolves,

2022. SD1 Project Proposal

We went through a meticulous design

process to arrive at the end results shown on this page. The information in

this page is a summary intended for the general public. To learn about the

project details, contact Dr. Noe Vargas Hernandez at noe.vargas@utrgv.edu

Our

team, the Mech Wolves, owe in large part the successes of this project to:

Dr. Yang, who gave us guidance and

advice.

Mahmodul Maheen for

significant theory, fabrication, and testing guidance and contribution.

Dr. Vargas, for general guidance.

Mr. Potter, for rigorous constructive

feedback and significant guidance on 3D printing.

Mr. Hector Arteaga for practical

specifics and fabrication guidance and advice.

Mr. Antonio Suarez for fabrication guidance

and advice.

The

Hi-Bay and Machine Shop employees and students, who freely assisted us whenever

we asked or simply looked like we needed help.