UTRGV / COLLEGE OF ENGINEERING AND COMPUTER

SCIENCE / MECHANICAL ENGINEERING DEPARTMENT

UTRGV / COLLEGE OF ENGINEERING AND COMPUTER

SCIENCE / MECHANICAL ENGINEERING DEPARTMENT

TEAM 8:

Wave Powered Autonomous

Underwater Vehicle

(Design

Process Page)

|

SDI Students (L-R) |

· Javier Benavides · Bryant Chiu ·

Fernando Guerrero Rivera ·

Gerardo Salinas |

|

Faculty Advisor(s) |

· Dr. Yingchen Yang |

|

Course Instructors |

· Dr. Noe Vargas Hernandez · Mr. Greg Potter |

|

College of Business and

Entrepreneurship Collaboration |

· Dr. Reto Felix

(Instructor) · Annet Del Toro Villarreal · Hugo Gutierrez · AnaKaren Rios · Omar Rodriguez Perez · Mayra Varela |

Back to

the PROJECT MAIN PAGE.

During Senior Design we followed a

design process to make the Autonomous Underwater Vehicle be able to travel from

point A to point B underwater using MRE (Marine Renewable Energy).

Problem ID

Problem Formulation

Conceptual Design

Embodiment Design

Testing and Validation

The

objective of the Problem ID stage is to help the user identify what the problem

to be solved is, as well as to brainstorm in order to

figure out a way to solve the problem. The team thought not only about what our

own take in order to solve the problem would be, but

also the competitors that are already on the field and how can we differentiate

our product from the competitors.

POG’S

There are many diverse types of

renewable energies such as solar, thermal, wind, and hydropower energy. The

team determined the best way to solve the problems is to utilize wave energy

(hydropower). Essentially, wave energy is produced via the frictional force

generated when the wind hits the surface of the ocean. As

it stands right now there is two methods of utilizing wave energy. One method

is to utilize the energy supplied by the wave and converting it into electrical

to power a battery housed in the system. The other method is for the propelling

force to be direct from the wave via mechanical systems.

VOA

The following VOA chart(s) compare our proposed

product to the closest(s) competitors:

|

AUV (Autonomous Underwater Vehicle) |

Team 8

G.B.J.F ENGINEERING |

|

|

|

|

|

|

|

|

ATTRIBUTES |

LOW |

MED |

HIGH |

|

Cost Efficiency |

|

|

• |

|

Energy Efficiency |

|

|

• |

|

Communication System |

• |

|

|

|

Depth Rated |

|

• |

|

|

Minimal Impact on the Marine Ecosystem |

|

|

• |

|

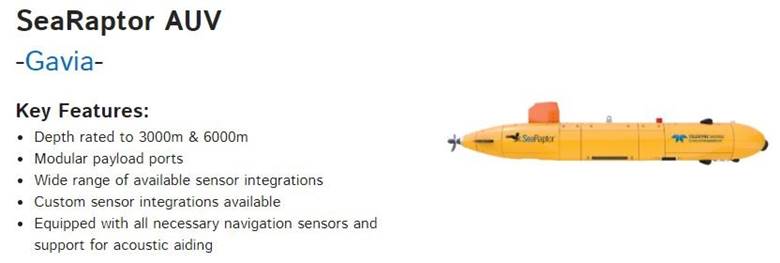

COMPETITOR 1: SeaRaptor |

TELEDYNE MARINE |

|

|

|

|

|

|

|

|

ATTRIBUTES |

LOW |

MED |

HIGH |

|

Cost Efficiency |

• |

|

|

|

Energy Efficiency |

|

• |

|

|

Communication System |

|

|

• |

|

Depth Rated |

|

|

• |

|

Minimal Impact on

the Marine Ecosystem |

|

• |

|

|

COMPETITOR 2: Comet-300 |

RTSYS |

|

|

|

|

|

|

|

|

ATTRIBUTES |

LOW |

MED |

HIGH |

|

Cost efficiency |

• |

|

|

|

Energy Efficiency |

|

• |

|

|

Communication System |

|

|

• |

|

Depth Rated |

|

|

• |

|

Minimal Impact on the Marine Ecosystem |

|

• |

|

As

you can see from the tables above, we determined our product will shine in cost

efficiency and energy efficiency. Since our AUV will not need to be retracted

to recharge resources will be saved there. Also, missions will be safer for those

in charge of the AUV.

FINAL PROBLEM

STATEMENT

While ocean robots

have proven to be particularly useful in many applications they are

limited by a crucial factor. Battery powered autonomous underwater

vehicles are limited by the capacity of its battery. Due to this problem,

they are limited to short term functions. As stated in the article a

battery powered AUV is limited to “hours to days” and “tens to hundreds of

kilometers. “[3] While the longevity and

physical capacity is our focal point, it is not the

only issue that would be resolved. A successful wave

powered AUV would open a world of exploration

for hydrographic surveyors, pipeline inspectors, and ocean observers.

The main objective of the problem formulation stage is to establish a clear problem. In order to do so we conducted extensive research on the following topics.

BACKGROUND RESEARCH

POWER SOURCES

AUV power

sources can be broken down into three categories nuclear, combustion, and

electrochemical. We

will be focusing on electrochemical.

There are four different categories of

electrochemical power sources.

· Pressure compensated batteries (batteries discharged at ambient

pressure)

· Batteries discharged at atmospheric pressure

· Fuel Cells

· Seawater batteries

Note: Outgassing is the formation of gases during charging. Outgassing

complicates charging and discharging. If a battery outgasses then the gases

must be removed from the cells to prevent an explosive environment.

|

Chemistry |

Energy Density (Whr/kg) |

Life (Cycles) |

|

|

Alkaline |

140 |

1 |

Outgassing during high temp |

|

Lead Acid |

31.5 |

100 |

Outgassing |

|

Silver Zinc |

100 |

30 |

Outgassing |

|

Ni Cad |

33 |

100 |

Flat discharge curve |

|

Ni MH |

60 |

500 |

No outgassing |

|

Li Ion |

144 |

500 |

Limited by depth |

|

Li Polymer |

193 |

500 |

No outgassing |

As it can be observed in the table above lithium

polymer cells possess great energy density, low weight density, and long life. Furthermore, they

do not outgas making recharging simpler.

Materials

Materials suitable for underwater navigation

need to have high strength-density ratio. Material such as metals have a

tendency of corroding underwater. Chemicals present in sea water that led to

corrosion are nitrates, acids, sodium, and other chlorides. The main question is

what can be done to minimize these factors to minimize the problem of corrosion

in sea-going vessels. The research was conducted by G.B.J.F. Engineering.

AUV Sensors

AUV's built-in sensors provide an

abundance of valuable information, such as depth. AUV's can be equipped with

still or video cameras, sonar, magnetometers, fluorometers and dissolved oxygen

sensors. AUV's can communicate with each other via radio waves, but radio waves

are not capable of navigating through water. AUV's utilize the last known GPS

information and makes use of a built-in inertial navigation system. The

function of the inertial navigation system is to document the vehicle's

rotation, acceleration, and velocity. This function is also known as "dead

reckoning" The profundity of the vehicle can be estimated using a sensor

capable of measuring pressure. AUV's may have various underwater

implementations. Commercial applications include observation of environment for

oil and gas industry and searching for wrecks. Military applications include

reconnaissance and anti-submarine warfare. It would also be innovative in the

research department. A long-range H-ADCP is incorporated in the AUV's payload

to measure wave flow tempo profiles. The profiles are used by the vehicle to

institute path rectification to improve the vehicle's robustness. The mission

is replicated when the vehicle arrives at the deduced wave field or when a

necessity to renovate the deducing wave field is found. The wave fields created

by the varying vortices supplies a rough estimate of the spatial wave

administration, which is based on the turbulent field effects. The number,

centers, and intensities of the vortices closest to the AUVs are determined

from the H- ADCP profile. The AUV then can map the trajectory with the least

amount of navigation time in the newly constructed sector. AUV's must be able to operate in ocean circumstances

distinguished by complicated ocean circumstances. Unpredictability of the ocean

can vigorously unsettle safety conditions and evolution of AUV missions.

Forecasting and learning ocean currents is an especially important obligation

to enlarge the AUV's safety when encountering unpredictability.

Communication

Communication underneath the water is based

on acoustic waves. It can take up to 2 seconds to reach back and forth in a

1.5-kilometer distance. Communication can be affected by scattering, refraction and absorption through the water. Hollow waters

and reef formation is where coordinated robotics can be most difficult to have

communication in the ocean. It is also difficult to communicate with robots in

hollow waters and reefs, which can be difficult for coordinated robotics. The

communication will be completed at a very low bit rate. This is due to physical

limitations which include delay and attenuation. Dolphins have given experts

inspiration to carry information based on location and communication. Engineers

came up with a tool named the "ultra-short baseline" (USBL) tool to

help with the communication. The USBL tool is based on chirps, which will be

used to communicate with the ship. The information will be sent in bytes and

kilobits, in the form of a frequency signal. The idea comes from dolphins' use

of singing and calls.

USBL is a type

of acoustic reading that can tell you positioning. It does this by being an

extension of a computer modem. Sound is transported from here towards the AUV

which then replies with a new pulse. This rebound signal can be read by a

computer located on the ship.

Coordinated

Robotics is a project that is of great importance to pave the way for future

underwater communication research. The company is working on such solutions to

fasten delivery time and create bigger chances for opportunity.

COMPETITIVE PRODUCTS

Due to the high

volume of competitors we narrowed down our

research to 7 AUVs. Each of these AUVs represent a subsection sharing

similar characteristics. Below is more

information pertaining to each of the 7 AUVs.

1.

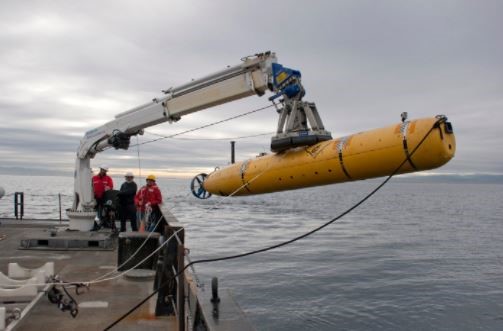

TELEDYNE MARINE

Because this is a modern technology, there

are few competitors. One of the main competitors is the company Teledyne

Marine, which is one of the leading companies in the development of AUVs. Its

main AUV is the SeaRaptor, which can travel from

3,000 to 6,000 meters deep.

URL: http://www.teledynemarine.com/searaptor-auv?ProductLineID=15

|

COMPETITOR

1: SeaRaptor |

TELEDYNE MARINE |

|

|

|

|

|

|

|

|

ATTRIBUTES |

LOW |

MED |

HIGH |

|

Cost Efficiency |

• |

|

|

|

Energy Efficiency |

|

• |

|

|

Communication System |

|

|

• |

|

Depth Rated |

|

|

• |

|

Minimal Impact on the Marine

Ecosystem |

|

• |

|

2.

RTSYS

RTSYS is a company based in France. This company

is specialized in underwater acoustics and robotics. RTSYS offers two varieties

of AUVs which serve similar purposes. The Comet-300 AUV offers advanced

navigation as well as a communication system capable of displaying navigation

and position data in real time.

URL: https://rtsys.eu/comet-300-auv

|

COMPETITOR 2: Comet-300 |

RTSYS |

|

|

|

|

|

|

|

|

ATTRIBUTES |

LOW |

MED |

HIGH |

|

Cost Efficiency |

|

• |

|

|

Energy Efficiency |

|

• |

|

|

Communication System |

|

• |

|

|

Depth Rated |

|

• |

|

|

Minimal Impact on the Marine

Ecosystem |

|

• |

|

3.

Monterey Bay Aquarium Research

Institute

MBARI is an advanced center for ocean research

and technology development located in Moss Landing, California. The development

of their AUV, has the purpose of investigating important marine areas, which

due to the lack of technology, have not been able to be investigated

properly.

URL: https://www.mbari.org/at-sea/vehicles/autonomous-underwater-vehicles/

|

COMPETITOR 3: DORADO |

MBARI |

|

|

|

|

|

|

|

|

ATTRIBUTES |

LOW |

MED |

HIGH |

|

Cost Efficiency |

• |

|

|

|

Energy Efficiency |

|

|

• |

|

Communication System |

|

|

• |

|

Depth Rated |

|

|

• |

|

Minimal Impact on the Marine Ecosystem |

• |

|

|

4.

Tiburon Subsea

Tiburon Subsea supplies renting and

lease facilities for global underwater technology. To provide vendors of

maritime facilities and businesses with the newest technology and assistance.

Their focus is on autonomous underwater vehicles (AUV) and a broad affiliate

network. Their engineering staff operates, trains

and provides services to a multinational AUV fleet whose systems are fitted

with payload packages including integrated benthos sonar systems, multi-beam,

sonar side scans, magnetometers and sensors for bathymetry.

|

COMPETITOR 4: REMUS |

Tiburon Subsea |

|

|

|

|

|

|

|

|

ATTRIBUTES |

LOW |

MED |

HIGH |

|

Cost Efficiency |

|

• |

|

|

Energy Efficiency |

|

• |

|

|

Communication System |

|

• |

|

|

Depth Rated |

• |

|

|

|

Minimal Impact on the Marine

Ecosystem |

|

|

• |

5.

Phoenix International

Artemis, the

Autonomous Underwater Vehicle of Phoenix International, is an

compact deep-water search/survey system that functions with two field-swappable

payloads. For effective single-pass data collection, the acoustic payload is a

multi-beam echo sounder, a dual frequency side scan sonar, and a sub-bottom

profiler that can be worked simultaneously. The optical payload is a high resolution payload that is (1936 x 1456

pixels) To build photomosaics of seafloor objects, the b&w camera was used. The geophysical payload is a

3-axis magnetometer, a 3-meter dipole electrical field (self-potential sensor),

a CTD and a bathymetric and backscatter running multibeam echo sounder. Doppler

Velocity Log, Ring Laser Gyro, and depth sensor combined with an Ultrashort

Baseline onboard inertial navigation system (USBL) The system produces

extremely precise, repeatable and accurate vehicle

navigation and positioning.

|

COMPETITOR 5: Artemis |

Pheonix International |

|

|

|

|

|

|

|

|

ATTRIBUTES |

LOW |

MED |

HIGH |

|

Cost Efficiency |

|

• |

|

|

Energy Efficiency |

|

|

• |

|

Communication System |

|

|

• |

|

Depth Rated |

|

• |

|

|

Minimal Impact on the Marine

Ecosystem |

|

• |

|

6.

KONGSBERG

The ultimate in autonomous remote

subsea survey capability is offered by KONGSBERG who provides the HUGIN

Autonomous Underwater Vehicles - AUV / marine robot. The great maneuverability

and high precision of stabilization characterize these free-swimming autonomous

underwater vehicles. The ideal choices for these AUVs are hydrodynamic shape,

precise instruments and outstanding battery

capacity.

|

COMPETITOR 6: HUGIN |

KONGSBERG |

|

|

|

|

|

|

|

|

ATTRIBUTES |

LOW |

MED |

HIGH |

|

Cost Efficiency |

|

• |

|

|

Energy Efficiency |

|

• |

|

|

Communication System |

|

• |

|

|

Depth Rated |

|

• |

|

|

Minimal Impact on the Marine Ecosystem |

|

• |

|

USER RESEARCH

·

AUV ́s AND THEIR MISSIONS AND

APPLICATIONS

An AUV can carry out a wide variety of activities. Analysis,

industrial applications and surveillance applications

are three major types. All these activities require human risk because they

require risk-taking.

AUV is an important instrument for collecting samples for

research studies. It is difficult for humans to do so largely because of the

high hydrostatic pressure. AUV's are also used in detection, search

and rescue, launch and recovery systems in the defense industries. AUVs are

used in the marine sciences, marine chemistry, marine geology, interstitial

water, marine biogeochemistry and underwater drilling

platforms.

·

AUV used in commercial applications

AUVs can also help in prevention and correction of maintenance

as well as inspection of activities. Underwater net opticfiber

has been created for underwater communications. AUVs can be used to monitor and

control underwater activities in the ocean. They can also be used for

underwater telecommunications in real-time.

Certain research created for

oil and telecommunication companies have been included in

literature. An AUV “equipped with an auto tracker, sensors such as

lateral search sonar, a geo positioner, shape recognizer based on

neural networks, so via the simulation of algorithms of each module,

incorporate into the physical part of the AUV.” [22]

Hazardous underwater

environments can be of great issue for not only access for humans, but also for

the AUVs; AUVs can be trapped during missions. When exploring through

solutions, a “C++ language can be implemented by estimating the error

between the position of the AUV and element.” [22] Such examples include

in pipelines or cable.

·

AUV used in surveillance applications

Subaqueous conditions are unforeseeable because of frequent alterations

of weather circumstances. There exists a very high chance that a military

operation will not succeed.

The independence of Autonomous underwater vehicles are characterized by two factors: “amount of

hours of operation necessary without occupying support and

the capability to make crucial commitments to undergo

a successful mission.” [22] Obviously,

the autonomy is a crucial feature in missions of surveillance, currently

research has been executed. New architecture of controls are

suggested to reach levels with characteristics of autonomy.

The autonomy of AUV ́s are represented by two aspects: number of hours of work

without needing any assistance and the ability to made decisions to carry out a

mission. The autonomy is an important feature in surveillance

missions, “research has been carried out where new control architecture

was proposed to meet the terms with aspects of autonomy referring to the

decision making in the missions in which the AUV ́s initially lacks

information.” [22]

DESIGN

SPECIFICATIONS

The design of the AUV will be made

taking in consideration the three distinct sections in

which the team has divided the vehicle. The

three sections that we have divided the vehicle are:

·

The Front Payload Bay

·

Power Take-Off Unit

·

Rear Payload Bay

The reason why the team

has decided to make this in the design of the AUV is because it helps the

assembly process. The assembly process is and must be of extremely

high importance since this could lead to imperfections throughout the

model, and when talking about an underwater vehicle there is plenty

of room for little mistakes to happen. Therefore, the team

in ordinance with Dr. Yingchen Yang

decided that creating this scheme will help avoid these tentative

issues towards the near future.

·

The Front Payload Bay

Regarding the Front

Payload Bay, the professor and advisor Dr. Yingchen Yang

mentioned something particularly interesting that the team

did not appreciate until it was commented with us, this is the fact that

when the AUV will be in different water circumstances you will always want it

to go down, even when we are not there to handle it ourselves. This made

us think that since the front part of the AUV, similarly to any other type of

underwater vehicle such as submarines, the first part or the part that leads

when the vehicle will sink. [23]

Therefore,

the form of the AUV must have a certain weight that will help the

overall body of the vehicle to sink even when there are storming conditions

that might bring it up towards the surface. [23]

·

Power Take-Off Unit

In the Power Take – Off Unit

section, the team will have to take in consideration for the design of

the AUV that the main component present which will be the stator

set, the battery pack, the magnets, as well as the

translator assembly. The stator set will be the non-moving

essential piece of the electric generator (also known as the motor) which

will help in the energy flow process as the stator lets the

energy navigate to the mechanical components of the AUV which will lead to

its movement. [23]

The battery pack will require to apply

some necessary specifications, as that this will be the only method for

which the AUV will be able to communicate and supply service due to no possible

way of receiving any source of charge in the middle of the ocean. An

important piece of advice that the team has acquired thanks to

research throughout distinct AUV models is that Lithium-Ion

batteries, seem to be some of the most reliable ways for us to store the energy

the AUV will be able to generate. [23]

An

important aspect that we must cover to have a good battery in the AUV is the

capacity of energy that it will be able to store. The capacity of the battery

will depend on factors such as the mass of body, its components, and the

surface of the AUV. The distance it can travel its directly proportional to the

weight of it. The AUV's battery capacity will also depend on its mass and the

temperature.

Therefore, the team will try to find a

suitable battery capacity once the overall weight of the AUV

is known. Inside the Fron Payload Bay

section, there will be the utilization of magnets to hold

in place the battery pack and avoid the movement of the batteries, this will

also help to hold up the section as a whole

and provide enough magnetism for the battery pack

installed. The AUV also counts with translators which will help with

the task of calculate the instantaneous position of the

vehicle in relation to the waves of the ocean, this will help

the AUV to approach the waves to gain kinetic energy out of it.[23]

An important piece of advice given to the team by

Dr. Yingchen Yang, is that the AUV must have a certain weight to it,

this will have to be acknowledged by the team when picking the different

polymer materials, and the amounts of it that will be used in the production of

the vehicle. The reason for the AUV needing to have a certain weight

is that the team must make the vehicle as

heavy as possible because this will be what will help it sink again if by any

reason is thrown off by a wave, by an animal that could uplift it to the

surface of the ocean, or by any outside effect. [23]

However, the team should

also make sure that it is not too heavy because if its weight happens to

surpass a certain mark then it will sink to the bottom of the ocean, therefore

a limit must be set regarding the weight of it. For us to

properly give the AUV the weight we are looking for the team was advised

to take in consideration the weight of the Battery pack as well

as the included magnets, since these will be the

ones responsible of the power generation for the vehicle, and

this in addition with the translator assembly will be the effective for the

team to manage the mass. [23]

·

Rear Payload Bay

Rear Payload Bay is composed of the propeller,

the ballast tanks, and the control and instrument sensor. The propeller will be

the necessary for the AUV to move from one place to another. If the propellers is affected or destroyed by some incident in the ocean then

the vehicle will find itself stuck with little or no room to repair it.

In order to avoid these

issues, the propeller must be made from a durable material that

can last for extended periods of time and will not damage. The damage

the material might suffer depends on distinct aspects such

as the temperatures under which it will be found, as well as the pressure

that it will be under and the type of water that the AUV will navigate as the

different pH these bodies of water might feature.[23]

Another

important part of the Rear Payload Bay will be the ballast tanks, which will be

filled with water for navigational purposes. When the AUV is positioned in the

surface level of the body of water, the ballast tanks will fill up

with air. This means that the whole density of the vehicle will be

significantly lower in comparison to the water, and it displaces. The AUV will

have to dive back into the water, and during this process, a vent will be

released and make the water in the surrounding of the AUV to dash inside.

Nonetheless, we must know

that this is not the only function the ballast tanks have, since they

can be filled up with not only water but with the amount desired of a

gas in a compress form, this with the purpose of submerge and go back to the surface

as the user desires. In this case the AUV will be able to back to the

surface, through the use of compressed air

which will be found in

the ballast tanks though an air flask and

this will propagate the water to get out by being pushed with a high

pressure and at a high speed which will make it easy for the AUV to

go back to the surface again.[23]

The team has also intended in

integrating a control and instrument sensor which will work in

regard to different formations found across the path of the AUV. These

sensors will be able to tell when possible damage

sources appear along the way and help the vehicle avoid them. The ocean is

difficult to predict in the sense that we are not able to know the different

settings it will encounter, as well as the different animals that are under the

sea and levels of water.

Ø Housing of

AUV

The housing of the AUV is one of the most

important parts of the vehicle, this will protect and keep together the

mechanism and since this will be under distinct circumstances, we

need to produce a material that can be utilized in the different

settings. [23] An advice that Dr. Yingchen Yang

gave to the team is to prioritize the housing of the AUV to remain in a

void environment, this is especially necessary because having any sort of leak

throughout the body of the AUV can cause the vehicle to sink and therefore

stop working and would be a complete failure. [23]

The housing of the AUV is intended of being

constructed out of a non-magnetic material because if it is intended

to be used for military purposes by the government, the team must use a

material that will not result affected is an enemy tries to steal the AUV

device by using magnetic devices. Also, because of the battery and the

magnets used to hold the battery together we must use non-magnetic materials in order to not affect the environment of the

power bank. [23]

The material necessary to build a proper AUV

housing must be made out of composite materials and/or

metal alloys. The ideal material for the housing of the AUV, would be out a

composite of titanium alloy. However, due to monetary constraints the team

needs to figure out a more affordable and easier to obtain material. The team

was able to notice the properties of this composite materials due to prior

investigations made by IEEE Xplore.

These composite materials are also extremely

helpful for the AUV because of their light weight this feature, as mentioned

above we need to have an essential weight to the AUV and having these

lightweight materials to our advantage will help us have more chances

of distributing the weight of the other components as we

desire. [23]

Another benefit of using this aluminum and

titanium composite material alloy is that the AUV

will feature a higher corrosion resistance across the

housing, it is imperative that the corrosion resistance of the vehicle must be exceedingly

high specially because it can go under unknown circumstances

when it is used for exploration or for missions by the NAVY. This

circumstances also require the freedom of changing the shape design

of the vehicle depending on the mission or the reasoning behind

it, and the aluminum alloy as well as titanium alloy give the

chance to the user of changing the shape of the AUV as

they desired, and it would be easier for the team to create a more

specific shape depending on the requirements. [23]

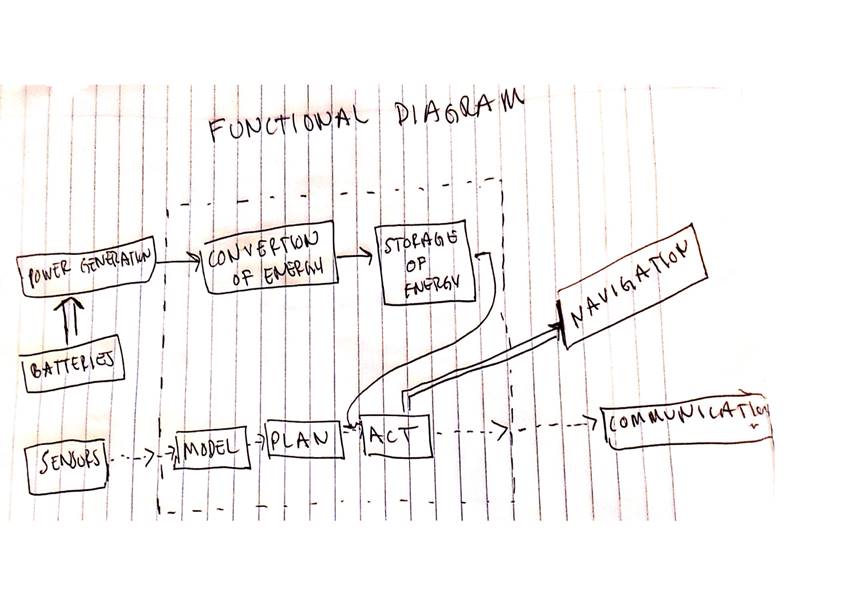

The

objective of the Conceptual Design stage is to determine the equipment

necessary for the assembly of the AUV. This while identifying what requirements

does the AUV has to fulfill. After the analysis of the essential parts of the

AUV, the team will identify how to integrate them in the system.

FUNCTIONAL DESIGN

MORPHOLOGICAL

CHART

|

Sub Functions |

Solution 1 |

Solution 2 |

Solution 3 |

Solution 4 |

Solution 5 |

|

Power Generation |

Use Solar Energy By adding solar

panels |

Use Wind energy

by adding a small wind turbine |

Integrating an

alternator system |

Using waves to

oscillate a spring system attached to a battery to charge |

Use an internal

combustion engine using biofuel |

|

Accumulation of

Power |

Implement lithium

batteries, known to be one of the longest lasting batteries in the market. |

Implement

alkaline batteries in high volume to withstand long distances. |

Utilize a backup

battery in case of emergency. |

Lead Battery (Car Battery) |

Vehicle 416mm Low-Voltage battery |

|

Communication |

Detection of

large objects via use of a detection radar. |

Implementation of

a GPS system so operator always knows location |

Implementation of

heat sensors, in order to perceive any unrecognized

activity underwater. |

Use of night

vision camera, in order to arrange missions during

dark/deeper environments. |

Typical Wifi band (2.4GHz) |

|

Being able to be

submersed underwater |

Use steel to

build AUV |

Use polymers to

build AUV |

Use more

sophisticated materials such as carbon fiber |

Use Aluminum

Alloys |

Use Titanium |

|

Military and

Border Security Applications |

Applying a small

security camera with low capacity for recording. |

Placing a GPS

system, to find location of illegal activities. |

Recognition of

heat patterns, to locate recent activity. |

Small device to

dismantle mines for military protection. |

Develop a UAV

capable of storing an anti-submarine explosive device. |

|

Data Collection |

Applying a small

tank for collection of water. |

A small imaging

system to capture images of the surroundings. |

Sensor of pH

balance in the different bodies of water, for research purposes. |

Integrate valves

on the surface, that can be controlled by the user to accumulate the samples

required. |

Collecting sand

samples |

|

Hydrodynamics |

Shape 1 |

Shape 2 |

Shape 3 |

Shape 4 |

|

|

Sub Functions |

Solution 6 |

Solution 7 |

Solution 8 |

Solution 9 |

Solution 10 |

|

Power Generation |

Use a

conventional high-performance electric motor. |

Implement a new design

in the AUV with the purpose of using ocean currents and generating electrical

energy. |

Use nuclear

energy as the main source to power the AUV. |

Implement an

engine which runs on natural gas |

Implementation of

the principles of osmotic energy to generate electricity through salt water |

|

Accumulation of

Power |

Vehicle 416mm High-Voltage battery |

Vehicle 310mm Low-Voltage battery |

Vehicle 310mm High-Voltage battery |

Vehicle 260mm Low-Voltage battery |

Vehicle 260mm High-Voltage battery |

|

Communication |

WLAN and Radio Communication |

Acoustic modems |

Frequency dependant attenuation |

Satellite

communications |

Aerostat hotspot |

|

Being able to be

submersed underwater. |

Use an

anticorrosive coating on the material used in the manufacture of the AUV

hull. |

Implementation of

anticorrosive paint on the hull and different components of the AUV exposed

to salt water |

Protection of

materials exposed to saltwater using anti-corrosion cathodic protection. |

Acrylonitrile Butadiene Styrene |

Ni-base Corrosion Resistant Alloy

|

|

Military and

Border Security Applications |

Used for wreck

inspection |

Install a defense

system capable of firing torpedoes against boats or mines. |

Implementation of

AUVs to check damaged ships after naval battles. |

Radar capable of

capturing electromagnetic waves generated by other ships. |

Capable to deploy

supplies to the army during war. |

|

Data Collection |

Equip the AUV

with a small drill capable of drilling stone at the bottom of the sea. |

Install a

mechanical claw to obtain aquatic plant samples. |

Equip AUV with a

net designed to catch small species of fish. |

Install a

compartment to collect fossils. |

Install a system

able to collect sounds and frequencies coming from the bottom of the ocean. |

CONCEPT VARIANTS

AND SELECTION PROCESS

The team had

to generate different concepts through CAD Software (Solidworks,

NX) and after having multiple variations of the AUV design, the team proceeded

to identify which AUVs designs would result to be more useful in the practice,

as well as with the recommendations of the advisor.

|

|

CV1 |

CV2 |

CV3 |

CV4 |

CV5 |

CV6 |

CV7 |

|

SF1 |

Wave energy with spring system 9,9 |

Alternator system7,10 |

Wave energy with spring system 9,9 |

Alternator system7,10 |

Wave energy with spring system 9,10 |

Alternator system7,10 |

Wave energy with spring sytem 9,9 |

|

SF2 |

Lithium batteries 7, 10,8,10 |

Alkaline 8,9,7,8 |

Lead 9,7,6,9 |

Lithium 7,10,8,10 |

Alkaline 8,9,7,8 |

Lithium 7,10,8,10 |

Lithium 7,10,8,10 |

|

SF3 |

GPS system 10 |

night vision camera 7 |

detection radar 7 |

GPS 10 |

GPS 10 |

Detection radar 7 |

detection radar 7 |

|

SF4 |

Alluminum Alloy 10, 10,10,10 |

Polymer 8,9,10,10 |

Titanium 7,10,7,7 |

Polymer 8,9,10,10 |

Alluminum Alloy 10,10,10,10 |

Titanium 7,10,7,7 |

Polymer 8,9,7,10 |

|

SF5 |

Small security camera 7 |

small security camara 7 |

GPS 10 |

small security camara 7 |

small security camara 7 |

GPS 10 |

GPS 10 |

|

SF6 |

Small tank storage 8 |

sand samples 9 |

small tank storage 8 |

sand sample 9 |

Sand samples 8 |

small tank storage 9 |

Small tank storage 9 |

|

SF7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FIRST ROUND |

CV1 |

CV2 |

CV3 |

CV4 |

CV5 |

CV6 |

CV7 |

|

SKETCH |

|

|

|

|

|

|

|

|

QUAL EVAL |

SCORE (1-10) |

|

|

|

|

|

|

|

Cost (SF1,SF2,SF4) |

8.67 |

7.67 |

8.33 |

7.33 |

9 |

7 |

8 |

|

Durability (SF2,SF4) |

10 |

9 |

8.5 |

9.5 |

9.5 |

10 |

9.5 |

|

Weight (SF1,SF2,SF4) |

9 |

9 |

7.33 |

9.33 |

9 |

8.33 |

8 |

|

Power stored (SF2) |

10 |

8 |

9 |

10 |

8 |

10 |

10 |

|

Portability (SF3, SF4, SF5, SF6) |

8.75 |

8.25 |

8 |

9 |

8.75 |

8.25 |

9 |

|

TOTAL |

46.42 |

41.92 |

41.16 |

45.16 |

44.25 |

43.58 |

44.5 |

|

CONCLUSION |

In conclusion, this combination is very interesting. It combines such advantages as using the material aluminum alloy which is very durable against corrosion and lightweight. Lithium batteries are of the most durable options available. Also small camera and gps sensor would not impact the portability of the AUV much. |

Disadvantages for CV2 include higher cost for night vision camera, and small security camera. Few advantages include durability and low weight for polymer. Overall, not considered. |

When in comparison with other combinations, CV3 presents some disadvantages. These include heavier weight for material titanium, as well as for the lead battery used. Overall, CV3 not considered. |

In summary, some advantages presented by CV4 include power stored from the lithium batteries, and lighter weight for alternator system, lithium batteries and the material polymer. |

CV5 is very similar to CV4 in having strong durability from alkaline batteries and alluminum alloy material. It also posseses strengths in cost efficiency with spring system as well as allumnium alloy. |

Major disadvantges for CV6 inlcude higher cost for alternator system, lithium batteries and the material titanium when in comparison with other materials. Overall, not considered. |

Some advantages for CV7 include power stored from the lithium batteries. Other advantages include high durability from these lithium batteries as well as from the polymer material. |

|

DECISION |

CONSIDER |

|

DNC |

CONSIDER |

? |

DNC |

? |

|

|

|

|

|

|

|

|

|

|

SECOND ROUND |

CV1 |

CV4 |

CV5 |

CV7 |

|

|

|

|

ROUGH CAD |

|

|

|

|

|

|

|

|

QUAL-QUAN EVAL |

VALUE (SCORE 1-10) |

|

|

|

|

|

|

|

Weight |

~32kg |

~15kg |

~55kg |

~15kg |

|

|

|

|

Cost |

High (10) |

Low (3) |

High (10) |

Medium (5) |

|

|

|

|

Range/ Durability of Battery |

High (10) |

High (10) |

Low (3) |

High (10) |

|

|

|

|

Charging Mode |

High (10) |

Low (3) |

High (10) |

High (10) |

|

|

|

|

|

|

|

|

|

|

|

|

|

TOTAL |

35 |

|

|

|

|

|

|

|

CONCLUSION |

In summary, the strengths… the weaknesses…. And comments… |

|

|

|

|

|

|

|

DECISION |

CONSIDER |

DNC |

? |

|

|

|

|

FINAL

CONCEPT(S)

After a process of elimination, we

arrived upon two final concepts. Model 1 uses a gyroscope method to

harvest energy. Model 2 utilizes a mass spring damper system to harvest energy.

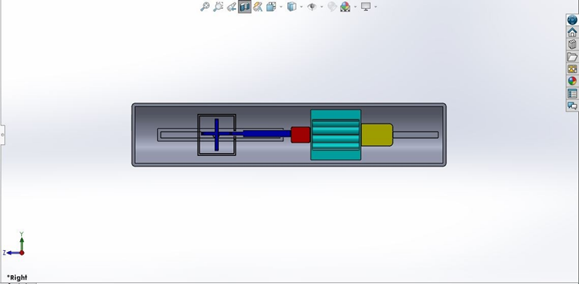

Figure 1: The present design consists

of a system whose main characteristic is the implementation of a gyroscope.

Theoretically, the gyroscope would move due to the movement of the waves.

Correspondingly, the mechanical movement of the gyroscope would be transformed

into electrical energy using a converter.

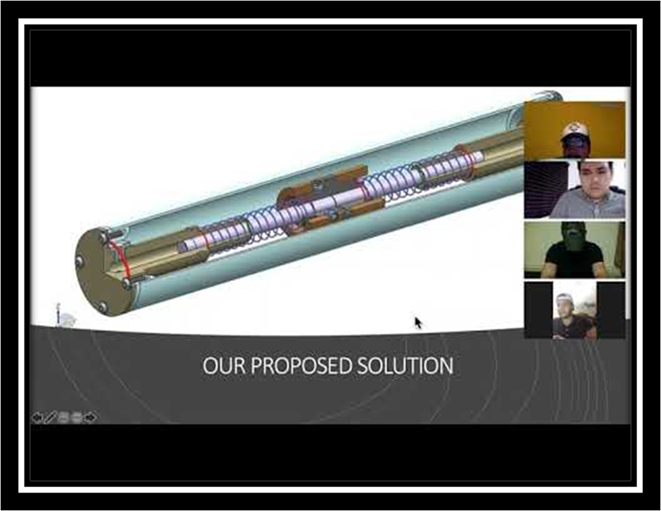

Figure 2: The second design implies

the implementation of a system which when moving with the mechanical energy of

the waves, the battery would generate an oscillatory movement which would

generate the recharge of the batteries by means of other compounds. The

electrical energy would be transmitted directly to the batteries.

The objective of the Embodiment

Design stage is to realize the concept previously designed.

STRATEGIES AND

PRIORITIES

Starting from our final concept, we

identified the necessary analysis and engineering work to realize the concept

into a product.

TASK 1: DECIDING

ENERGY HARVESTING METHOD

In order to

decide between the gyroscope method or the mass spring damper system, we did a

process of elimination. First, we

analyzed a gyroscope method previously used by Nicholas Townsend from the

University of Southampton.

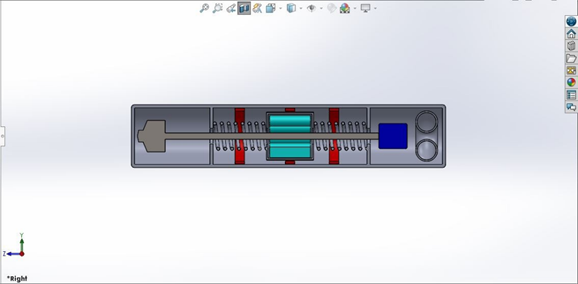

Figure: An Illustration of the

gyroscope system used in the model. [24]

Two studies in two different circumstances were done. One with high waves at a height of around .15m, the other with waves of around 0.1m. The power generated was then plotted and compared. [24]

Figure: Power Generated in both

circumstances [24]

From the

figure above it can be observed that even though the maximum generated power is

promising, consistency is not there. As it can be seen there is moments were

power is not even generated.

A quick calculation of friction encountered during underwater

travel was done to determine how much power is needed to overcome it. [24]

Power = ((½)*Iyy*Wf^2)/t,

where (½)*Iyy*Wf^2 represents stored kinetic energy

& t=time for flywheel to slow down from 5100 rpm to 0

Power = (0.5*0.00482*(5000*2pi/60)^2)/710 = 0.9W

From this calculation it can be observed that

even at maximum power generated levels, which are rare, it takes almost 1/3 of

the power generated to overcome friction. [24]

After these results it was determined to stop

further developing this final concept. The efficiency of the gyroscope method

was not appealing at all. [24]

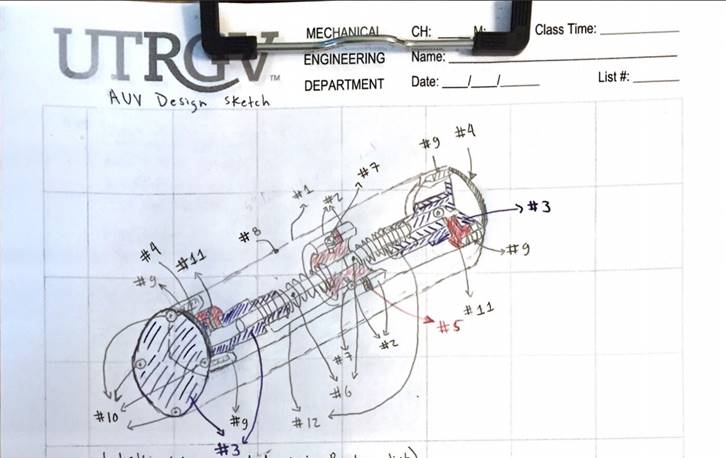

TASK 2: CREATE A DESIGN SKETCH

The team created a design sketch of what the assembly should

look like prior entering in the CAD design phase. This came alongside labeling

the distinct parts that will be required with the purpose of starting to make our

Purchas Approval Form.

Figure: Design Sketch

Figure: Part

Labeling

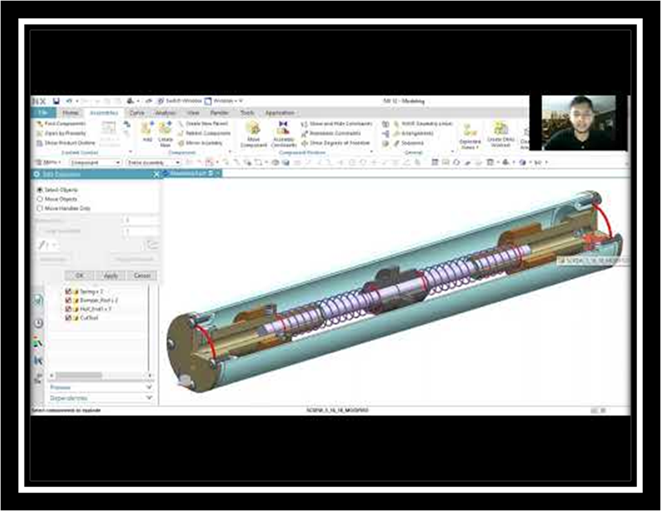

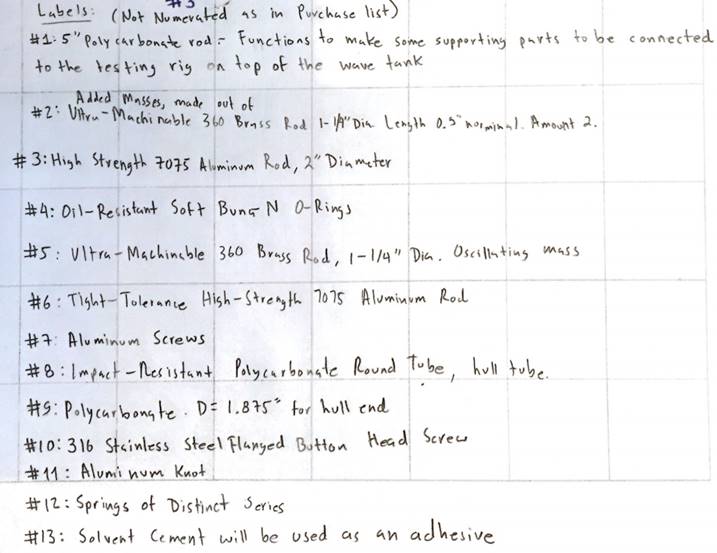

TASK 3: CREATING

A MORE DETAILED CAD OF OUR CHOSEN FINAL CONCEPT

After

finally arriving on our final concept, we had to bring this concept to reality. Here is how we did

it.

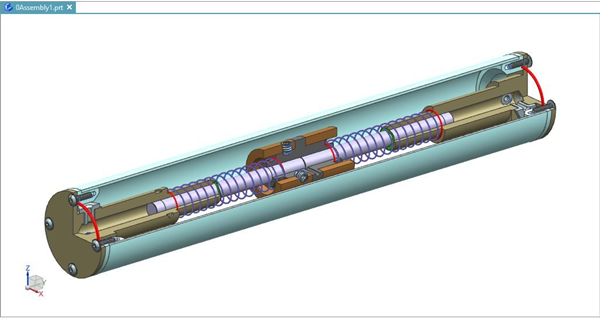

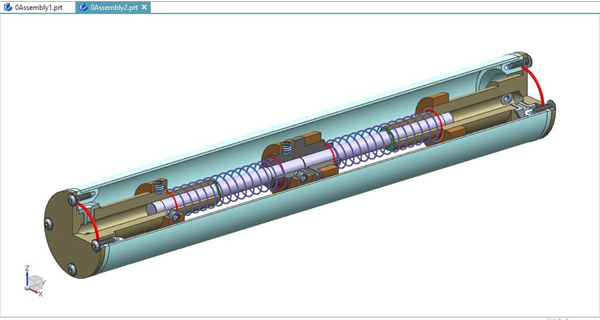

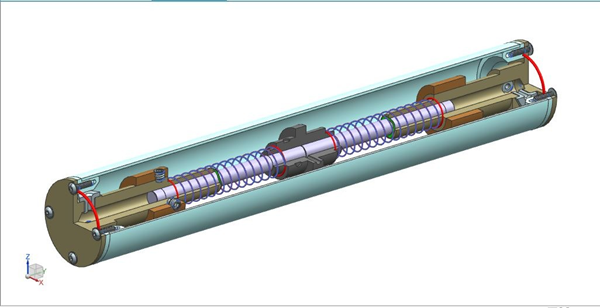

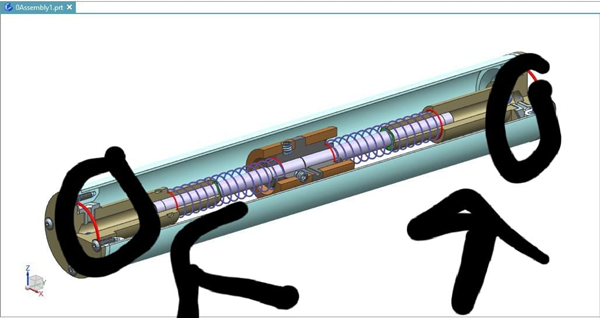

Figure: Detailed

CAD model using NX12 software

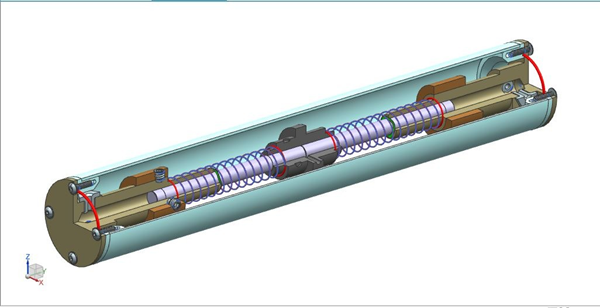

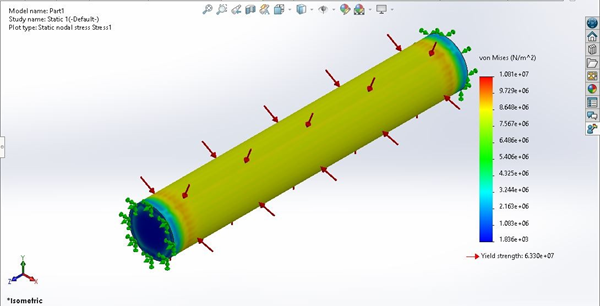

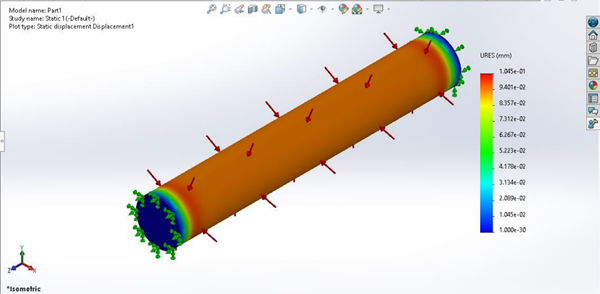

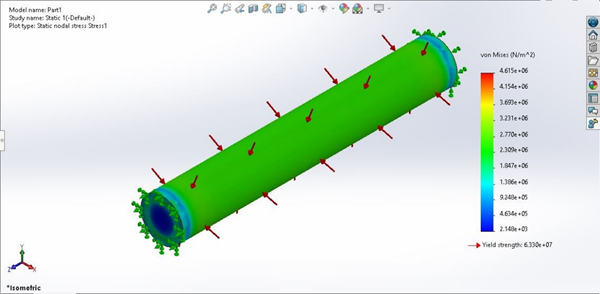

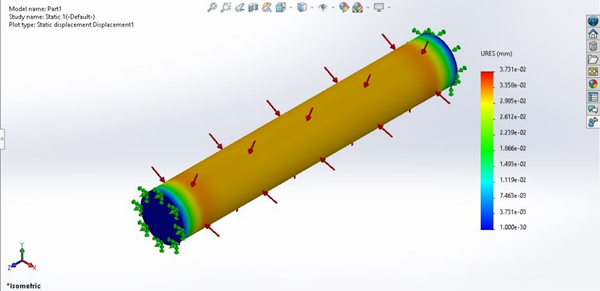

TASK 4:

DETERMINING HOW THICK THE HULL SHOULD BE

In order to

determine how thick, the hull should be we conducted finite element analysis on

the basic geometry of the hull. We did

the FEA analysis twice changing the thickness every time. We started at a thickness of 0.5

inches, followed by 0.2inches. We applied the load by using the

formula P = pgh +Patm. At a

depth of 100m, to be conservative. Where the density is 1030 kg/m^3,

gravity is 9.81 m/s^2, and pressure atmosphere is 101,325 Pascals. Therefore, the

hydrostatic pressure applied is 1,111,856 Pascals.

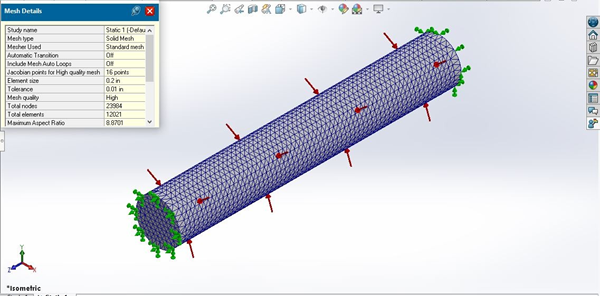

FEA ANALYSIS WITH THICKNESS 0F 0.2 INCHES

Figure: Mesh

created with a mesh size of 0.2 inches containing 12021 elements

Figure: Stress Analysis

Figure: Deformation Analysis

The hull

suffered no deformation with a thickness of 0.2inches as it can be observed in

the figure above.

FEA ANALYSIS WITH THICKNESS OF 0.5

INCHES

Figure: Stress Analysis

Figure: Deformation Analysis

Neither

thickness suffered no deformation. Therefore, it was decided to move

forward with a thickness of 0.2 inches in order to

conserve mass and resources.

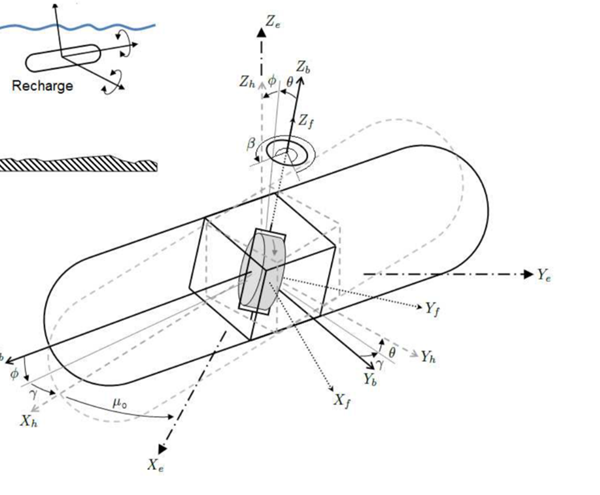

TASK 5: STABILIZING AUV

As the

springs oscillate the mass, it is obvious that the AUV will not remain stable.

Causing it to tip over.

To combat this issue, it was determined that we must oscillate

the mass in two parts.

Each time keeping the mass oscillating on each side even. We will explain it

using illustrations. Pay

close attention to the center mass.

Figure : Stabilizing AUV

Figure: Stabilization of the AUV

Figure: Stabilization of the AUV

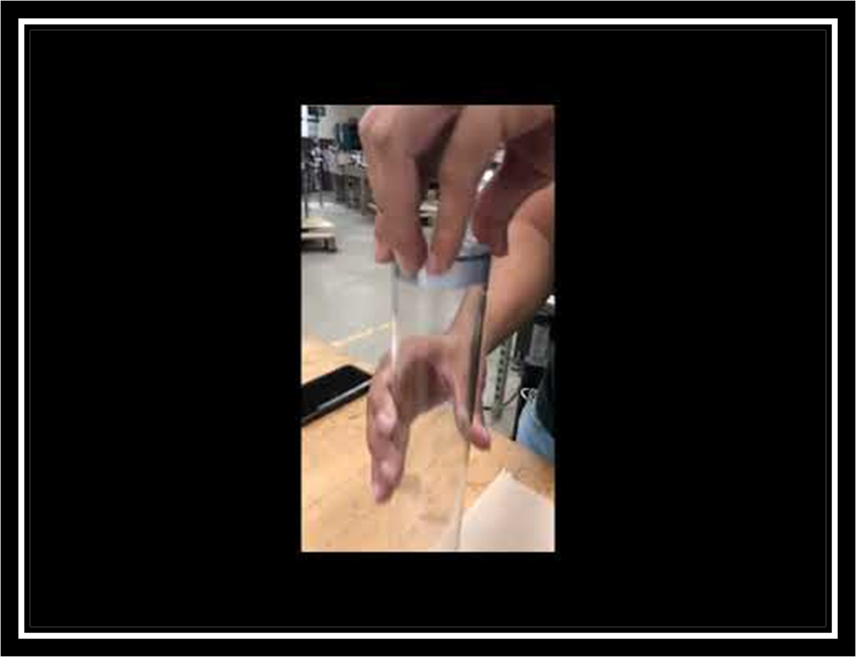

TASK 6:

USE MEASUREMENTS FOR DEVELOPMENT OF EARLY 3D PROTOTYPES

After making

the necessary design sketches, the appropriate 3D CAD designs, and acquiring

the necessary measurements, the team proceeded to create its first 3D

prototype. As we can appreciate the prototype its on

early stages of development, but the assembly of the parts required results

successful. This will help the team have a better point of view regarding how

to proceed in the next task.

Figure: Overall

view

Figure: Rear view

Figure: Top view

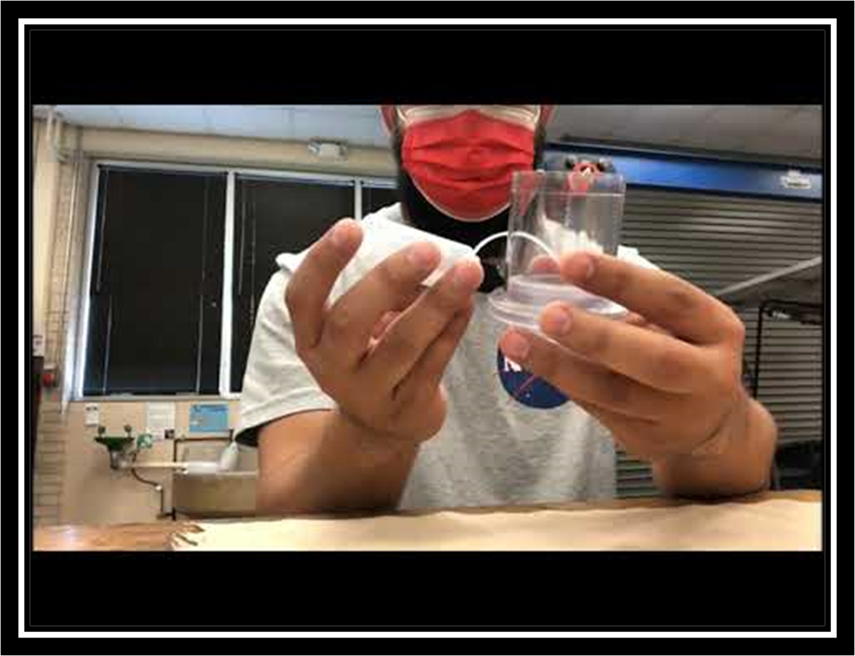

TASK 7: PREVENTING

WATER FROM LEAKING ON AUV

Water leaks

will be prevented using an O-ring. Rubber is used to make these bits. Two

aluminum parts will be mounted on either end of the AUV using the appropriate

screws, sealing the AUV and stopping water from entering. These components will

be machined in accordance with the requirements.

TASK 8:

CREATING A DAMPER

The

oscillatory movement in the central mass is caused by the mechanical movement

of the waves in combination with the stainless steel, causing the aluminum rods

to go up and down like a piston. When this is combined with the aluminum

chamber built to the design specifications, a damper is made. Air would be

pushed into the chamber by the aluminum rod, causing resistance.

TASK 9:

CONTROLLING THE DAMPING COEFFICIENT

We made the observation that the air pushed into the chamber

may create an exaggerated damping coefficient resistance. Making it difficult for the springs to operate. In order to control

this issue a hole will be drilled on each side of the chamber. Each hole will have an integrated release

system for best optimization of the damping coefficient.

Figure: Release system

TASK 10:

OPTIMIZING OSCILLATE PERFORMANCE

To optimize

oscillate performance, different spring sets can be used on the design,

allowing the best spring constant to be used based on the desired performance.

Two disk springs are used to shield the parts and improve the bouncing

movement.

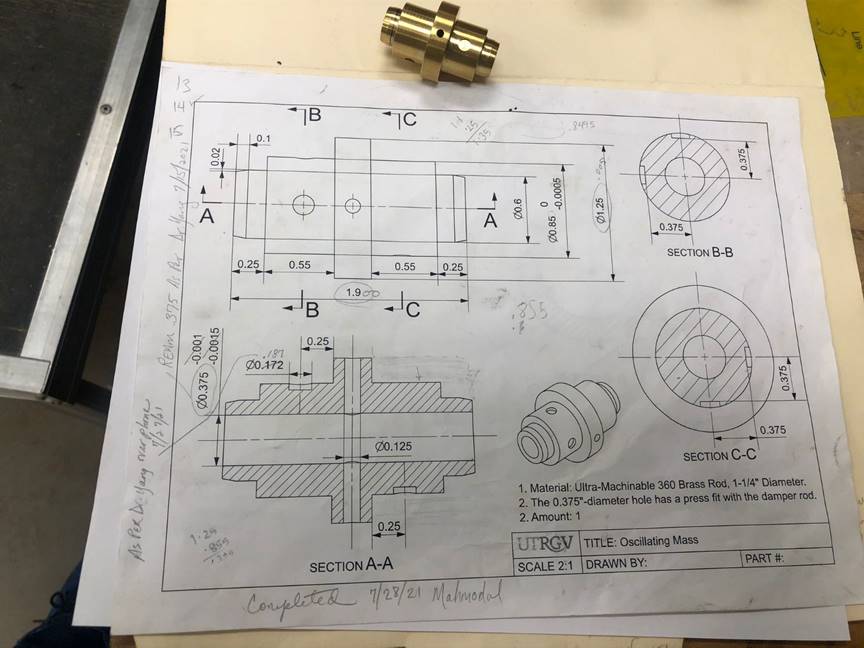

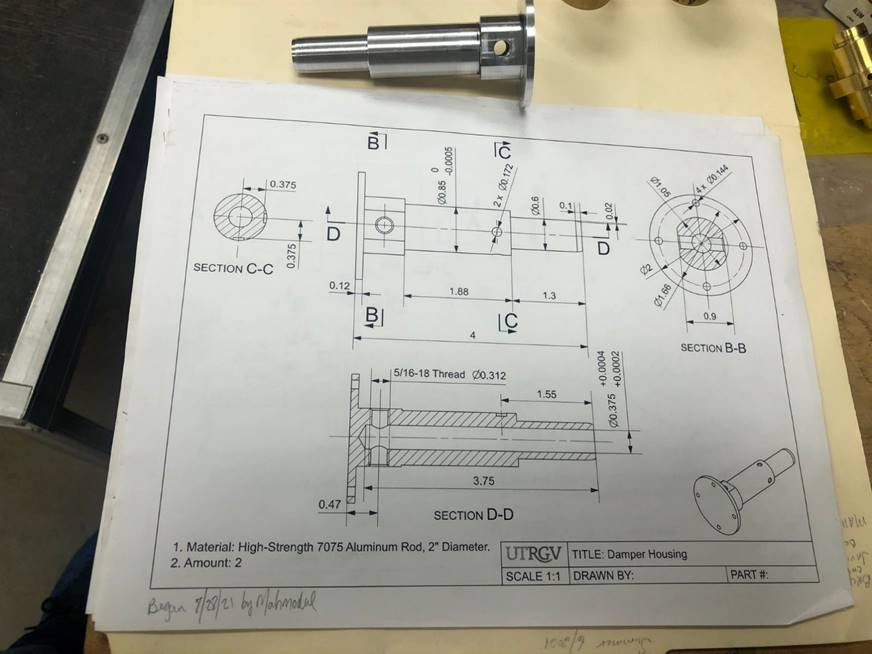

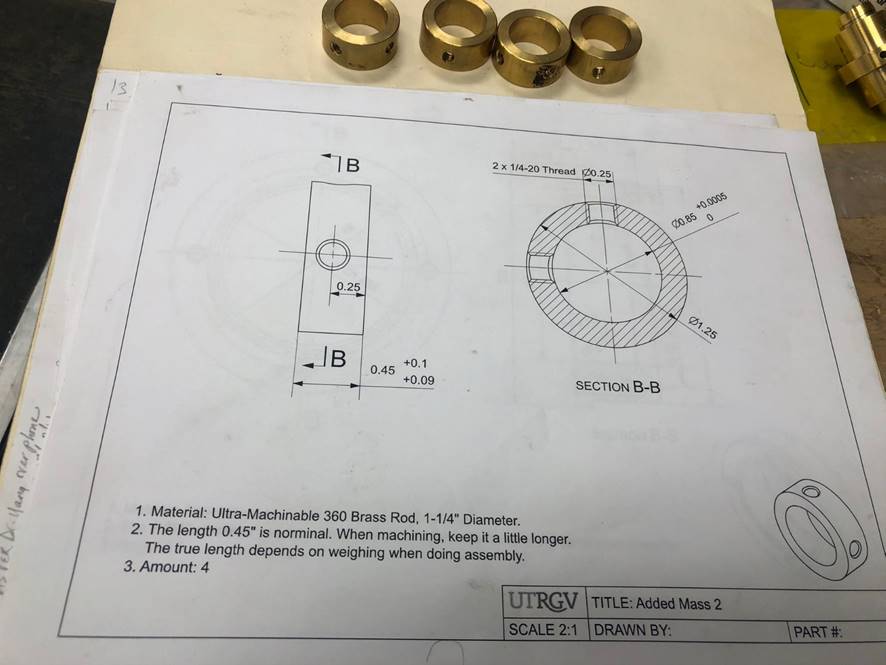

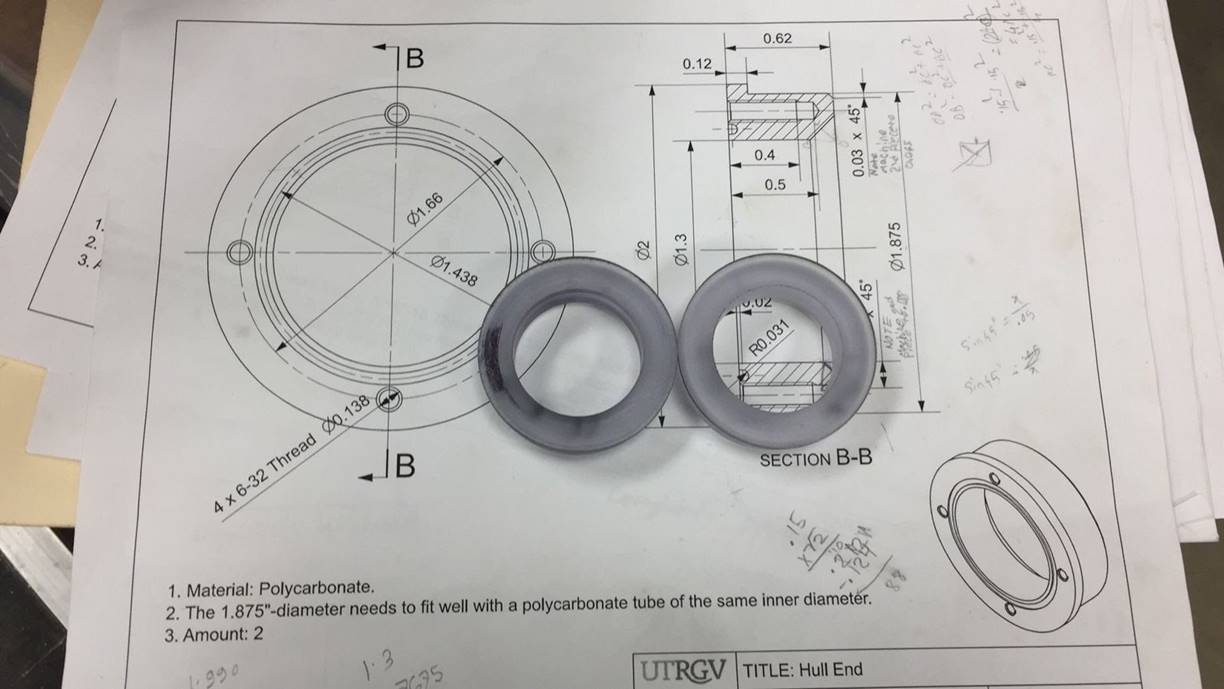

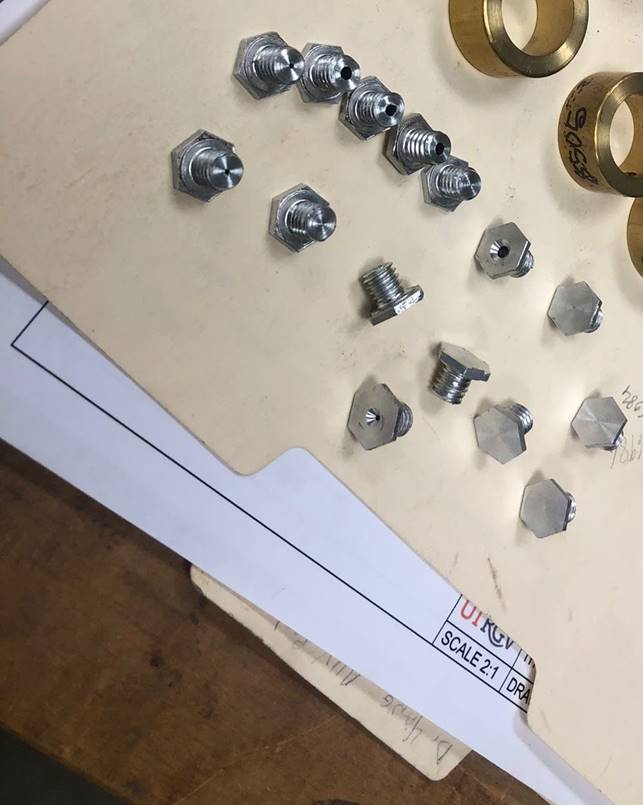

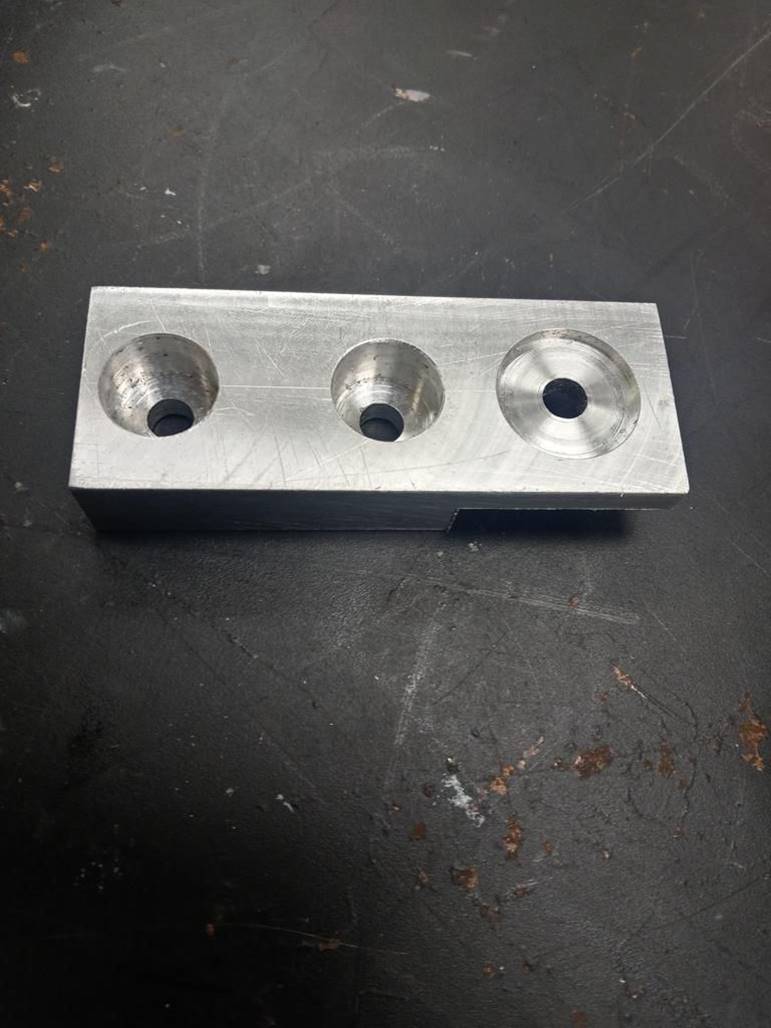

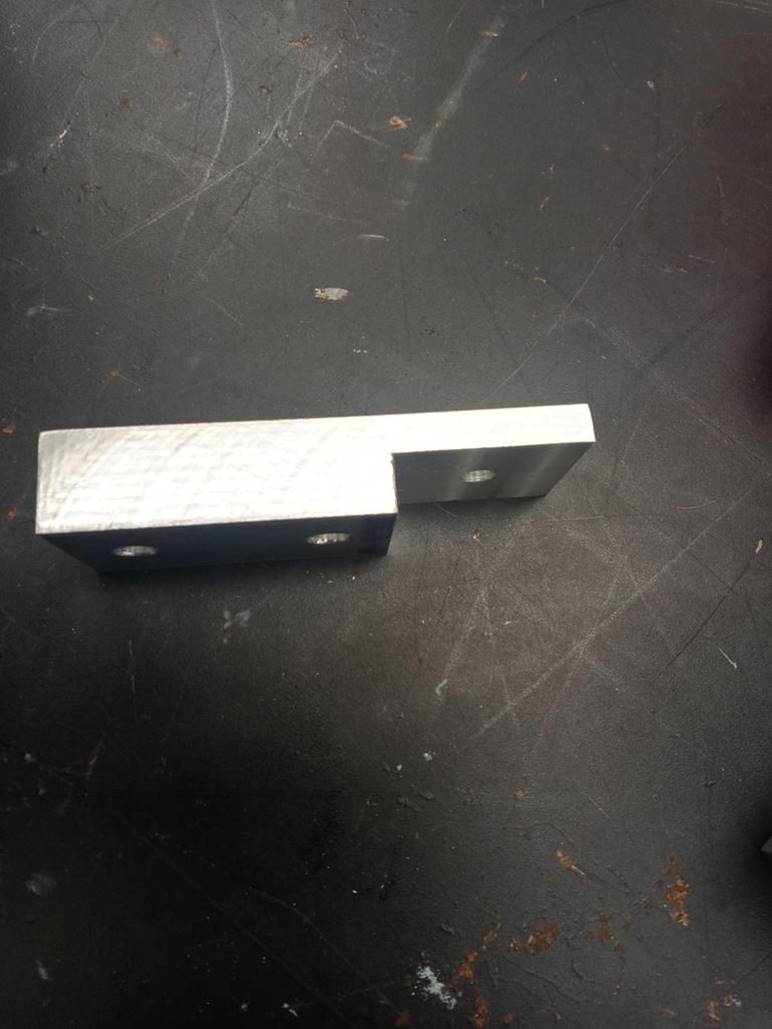

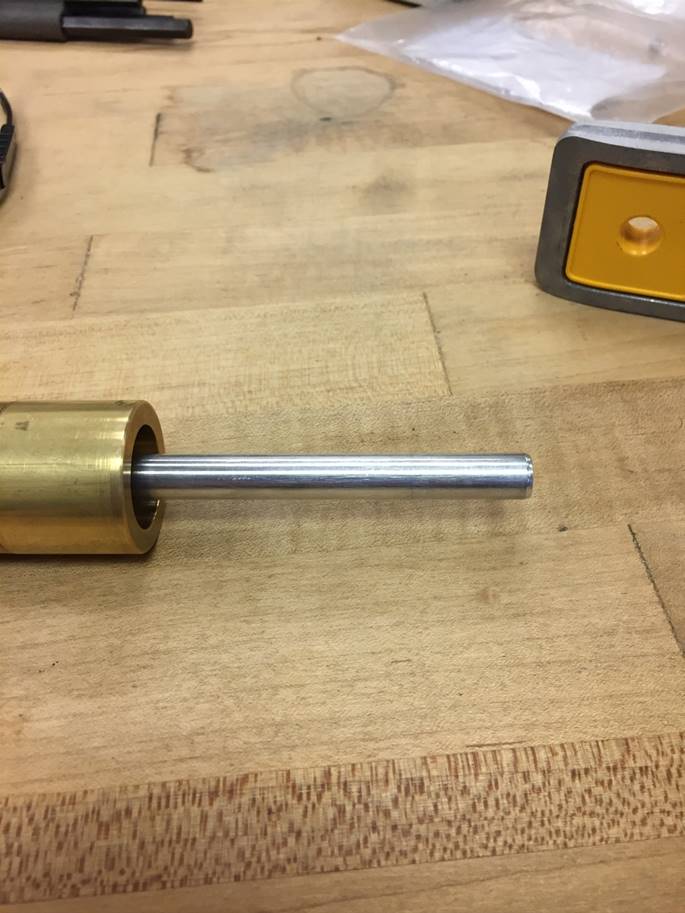

MACHINING PROCESSES

Above we can appreciate the machining

process for the parts of the AUV which use the following material:

Ultra-Machinable 360 Brass, High-Strength 7075 Aluminum, and Polycarbonate.

The presented piece is an oscillating

mass made of Ultra-Machinable 360 Brass. The oscillating mass is a central

component of the AUV, and its function is to oscillate with the movement of the

waves. It’s 0.375 ‘’ hole has a press fit with the damper rod, and a total

length of 1.9’’.

The damper housing is made of

high-strength 7075 aluminum, and its function is to work as a damper. The holes

on this piece are meant to regulate the compressed air. The total length of

this piece is 4’’ and a outside diameter of 2’’.

The following two pieces are

components of added mass 1. These parts are made of Ultra-Machinable 360 Brass,

with the main function to facilitate the oscillatory movement of the

oscillatory mass. The total length of each of the pieces are 0.9’’ and a outside diameter and inner diameter of 1.25’’ and 0.85’’

respectively.

The four machined parts presents are

made of Ultra-Machinable 360 Brass and are components of added mass 2. The

purpose of creating both added masses is to find the perfect combination to

improve the oscillatory movement of the center mass in a more efficient way.

The length of each piece is 0.45’’ and an outside diameter and inner diameter

of 1.25’’ and 0.85’’ respectively.

Shown above we can appreciate the

blueprints for the distinct AUV parts that were machined through the Summer.

Above we can appreciate the finalized

machined parts necessary for the assembly of the AUV. The parts machined

included the following: Ultra-Machinable 360 Brass, High-Strength 7075

Aluminum, and Polycarbonate.

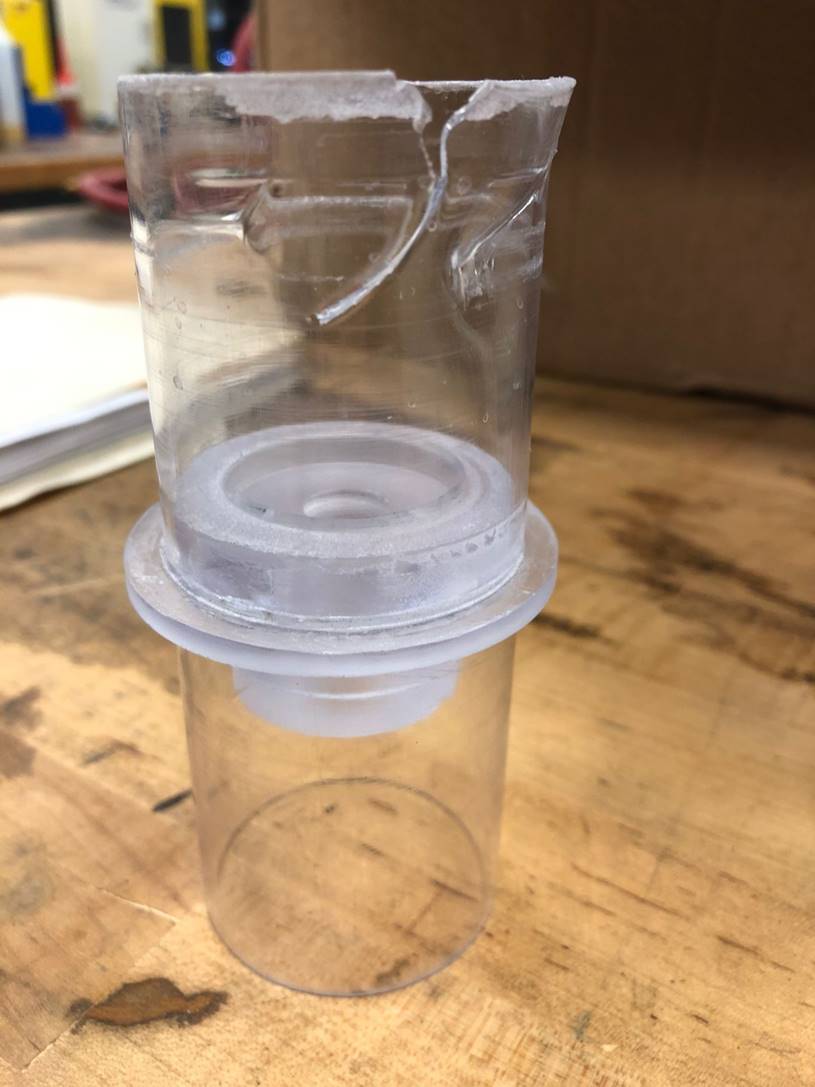

The following part is made of

polycarbonate, and its function is to seal the AUV by connecting it against the

damper housing. The outside diameter of the piece is 2’’, with an inside

diameter of 1.3’’.

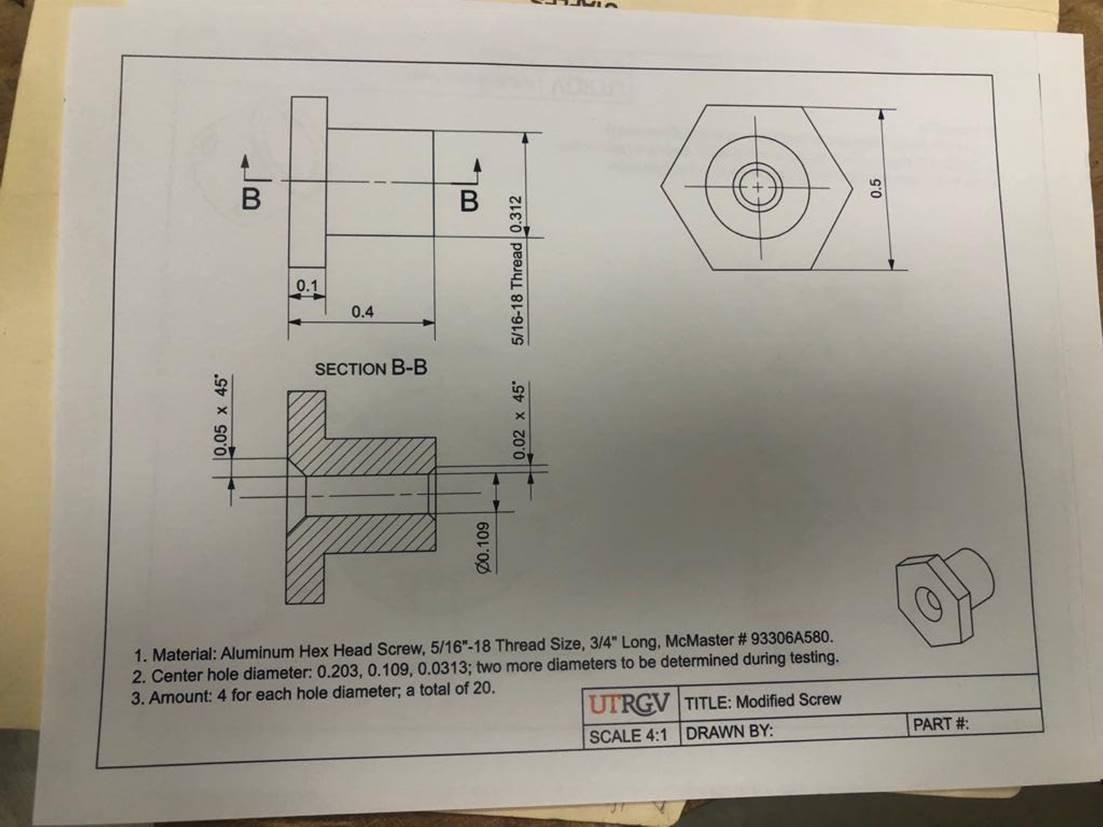

Presented above are the machined

aluminum screws, which are going to be implemented as an escape valve in order to regulate the compressed air in the damper

housing. There are 5 sets of screws, each set has a different center hole

diameter in order to find the correct combination for

a more efficient performance.

Shown above we can appreciate the

machining process required for the Polycarbonate, creating the end caps

necessary for the AUV.

Above we can appreciate the fit testing

process of the AUV caps, as well as the fit and placement of the O-rings before

proceeding with the application of the adhesive cement.

One of the challenges faced while

practicing the application of the adhesive cement was that if this process was

not done properly and did not cover the entire surface, as well as if it was

not given the proper time to dry this could lead into it breaking the piece and

detaching from the surface when force was applied towards it.

Items used for fixing the

polycarbonate ends.

The process of testing how the

adhesive cement works was done in order to prevent any

mistakes at the actual time of applying it to our finalized AUV model, and that

is shown above. We can also appreciate the final application of the adhesive

cement to the AUV model, with the purpose of achieving a snugger fit.

In the images shown above we can find

a visual representation of the AUV model, which demonstrate the assembly

process.

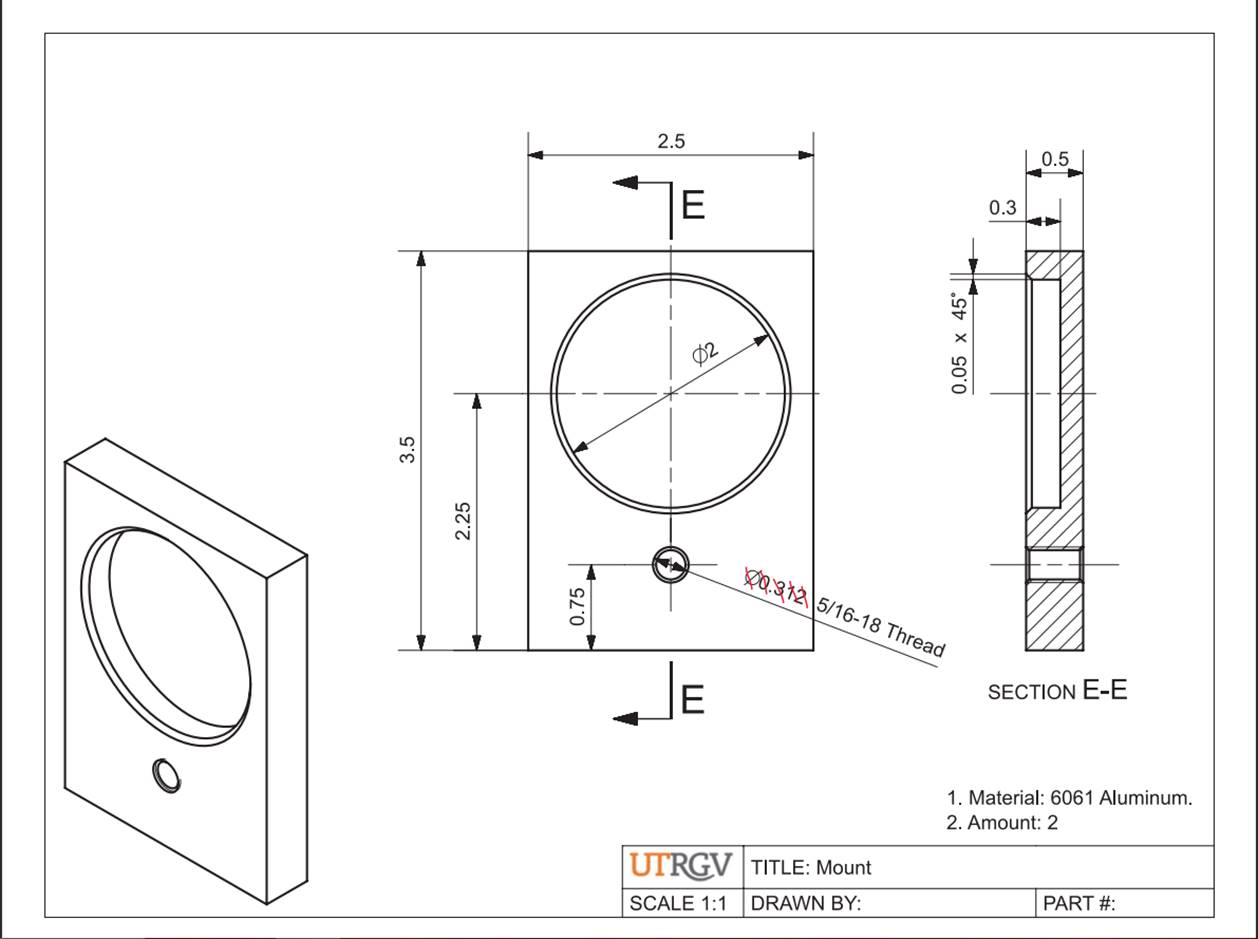

Mount and

Connector Footprints

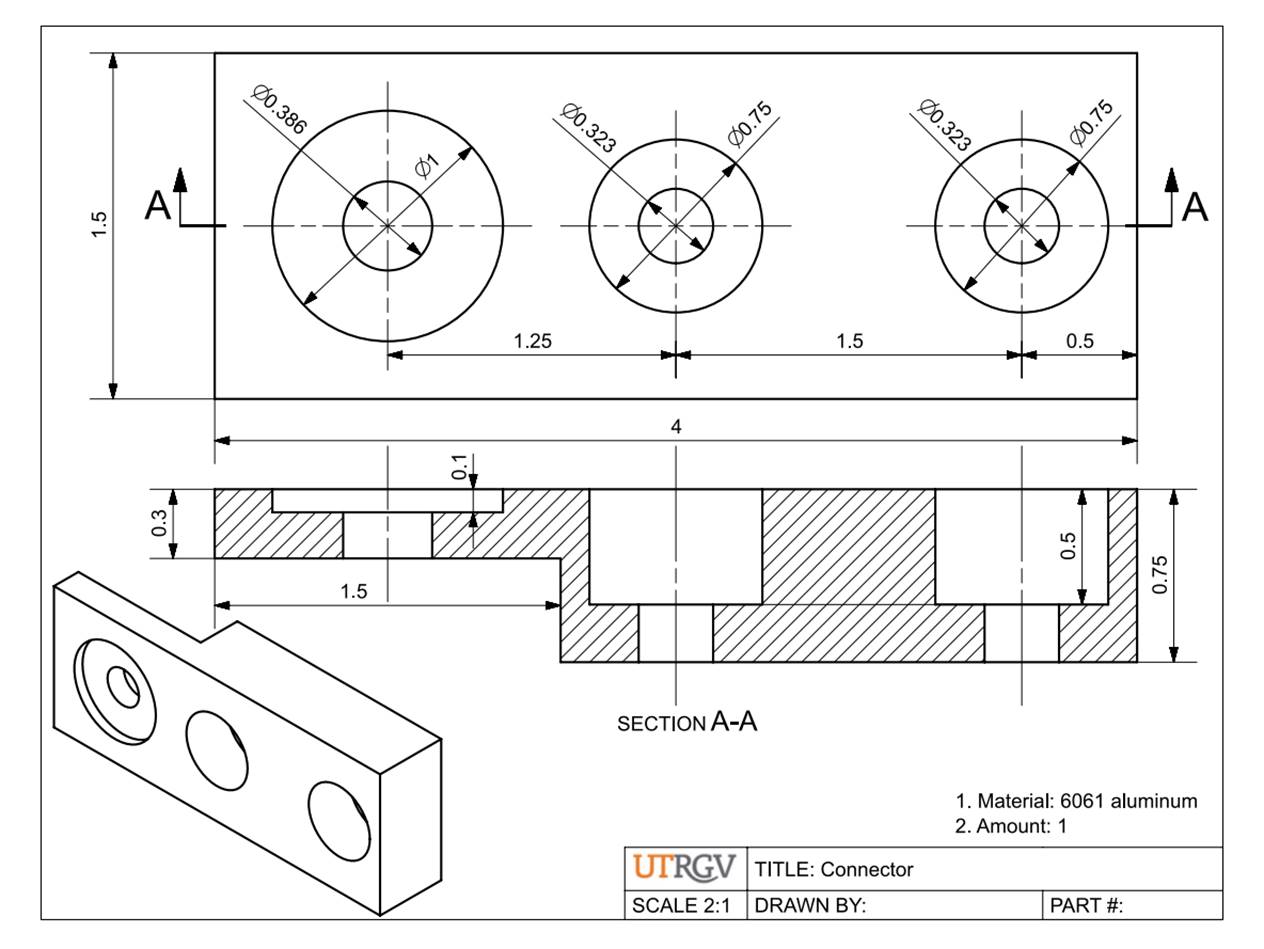

In the image shown below we can see

the footprint for the mount piece. This mount piece has been decided to be made

of 6061 Aluminum.

In the image shown below we can see

the footprint for the connector piece. This mount piece has been decided to be

made of 6061 Aluminum.

AUV Camera

Mount

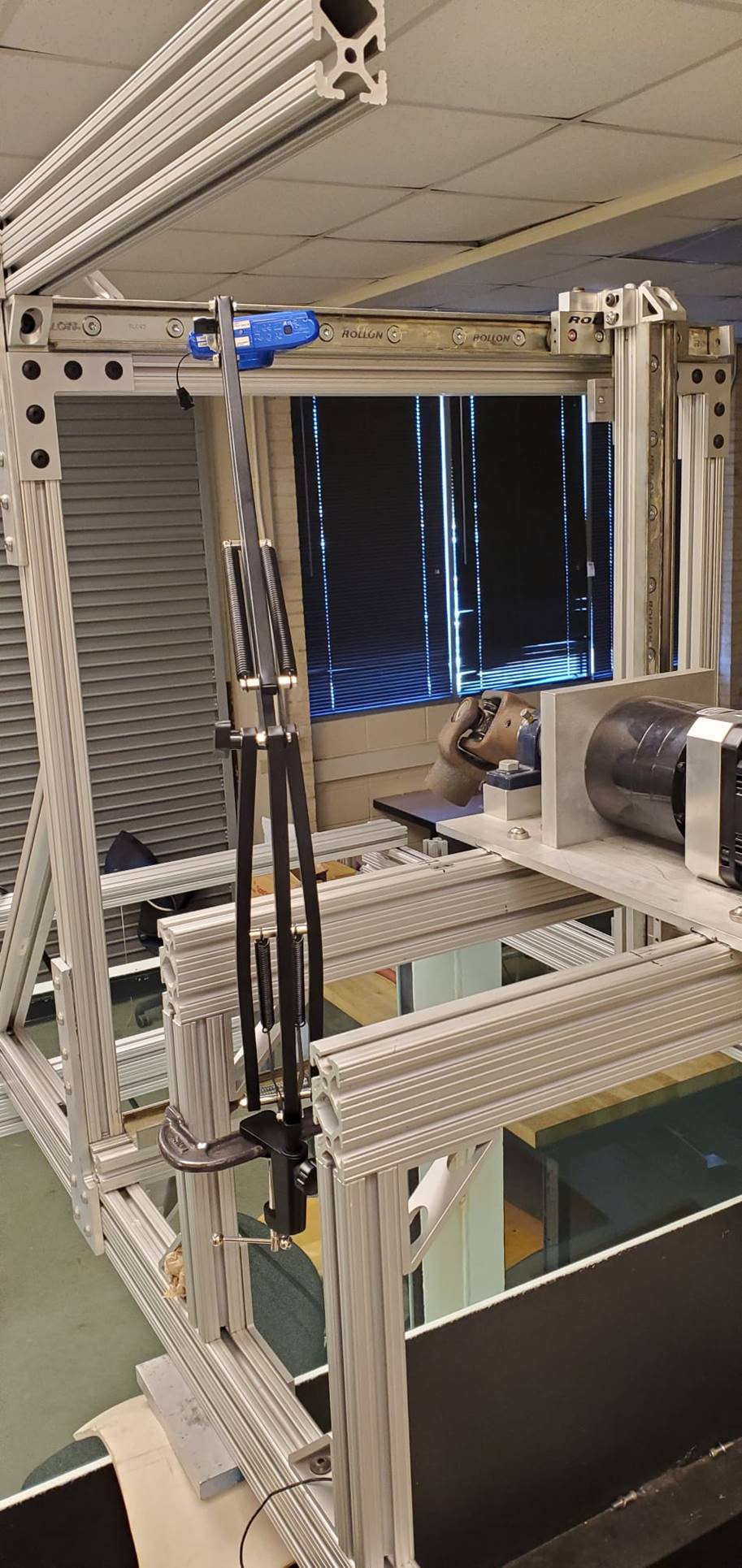

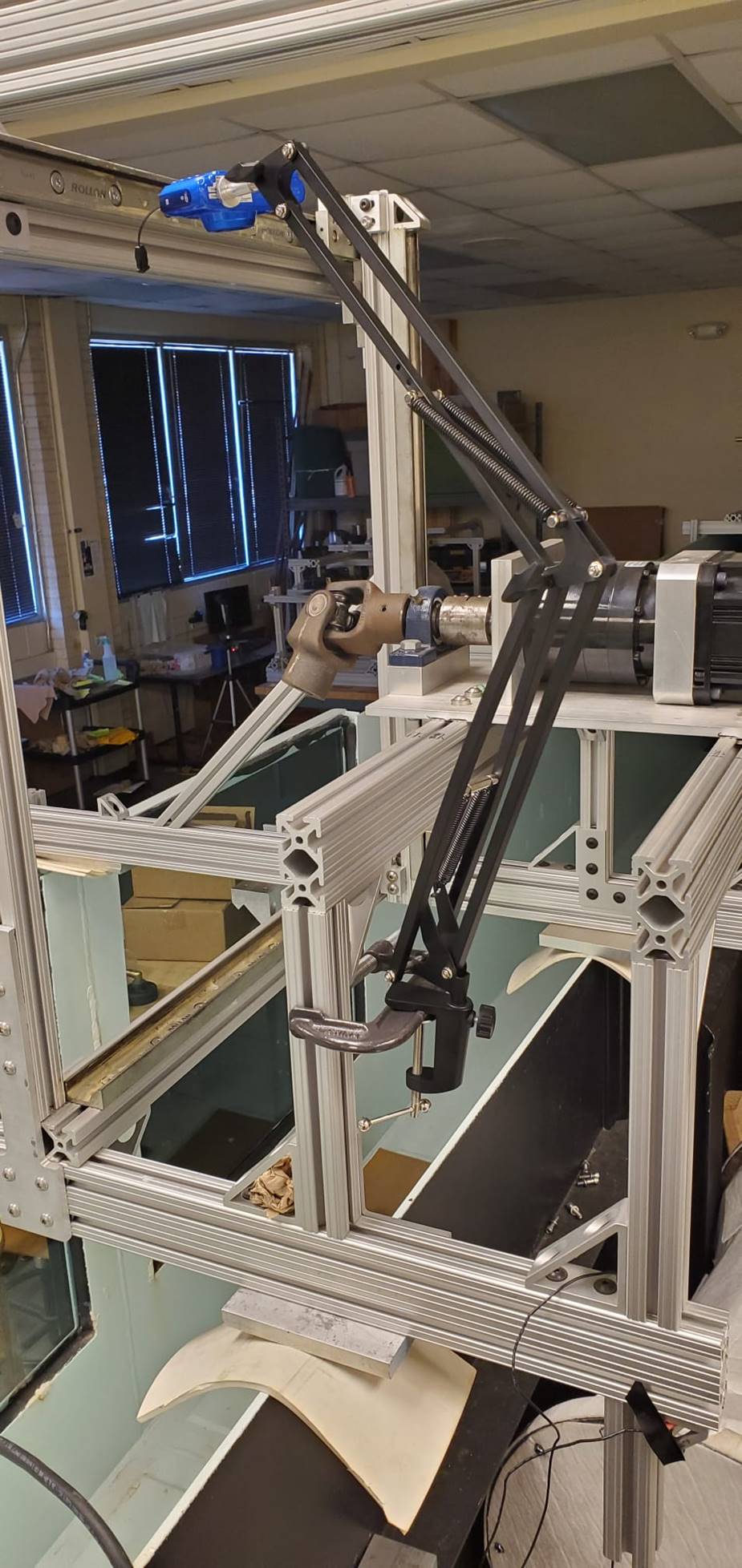

Team installed a Camera system to

observe movement of the oscillatory mass inside the AUV. Currently camera is

mounted to a fixed beam. In the future team will have to mount camera to a

moving beam so AUV can be observed as it moves about the x,y,z plane.

Assembly

Challenges

A challenge the team is

facing is that after assembling the AUV caps and tightening them up, the mass

does not move as expected. As you can appreciate in the images above, to solve

this issue the team loosen up the screws in the AUV and this are the results we

obtained. As you can observe the mass does move but not very smoothly, and we

are afraid this can cause some leakage to happen too.

After showing

results to Dr. Yang, we understood that loosening

up is just the first step. The team needs to fasten the screws again. But we

must fasten them correctly to achieve a good alignment for a smooth

oscillation. We will have to try it over and over again

in different ways to fasten them until we achieve the expected performance.

In the video shown above, we tried to

troubleshoot for the reasoning behind why the rod does not run as smoothly as

expected. The latest hypothesis is that as we can see in the image one end of

the rod was not filed correctly. In the first part of the video, we see the

side of the rod that was filed all the way through, and it slides smoothly when

compared to the second part of the video where when testing the other side of

the rod we can see the opposite.

ANALYSIS

The team in association with Dr. Yang decided that it was

better to concentrate in the damper mechanism for this project, for which

reason we will not be able to collect the data of how much energy it generates,

instead will concentrate in the theory side of the project. The team would

consider the mechanism to work properly if the energy generated by the waves

shows the damper mechanism to work as expect by creating a transversal movement

that should generate the power necessary.

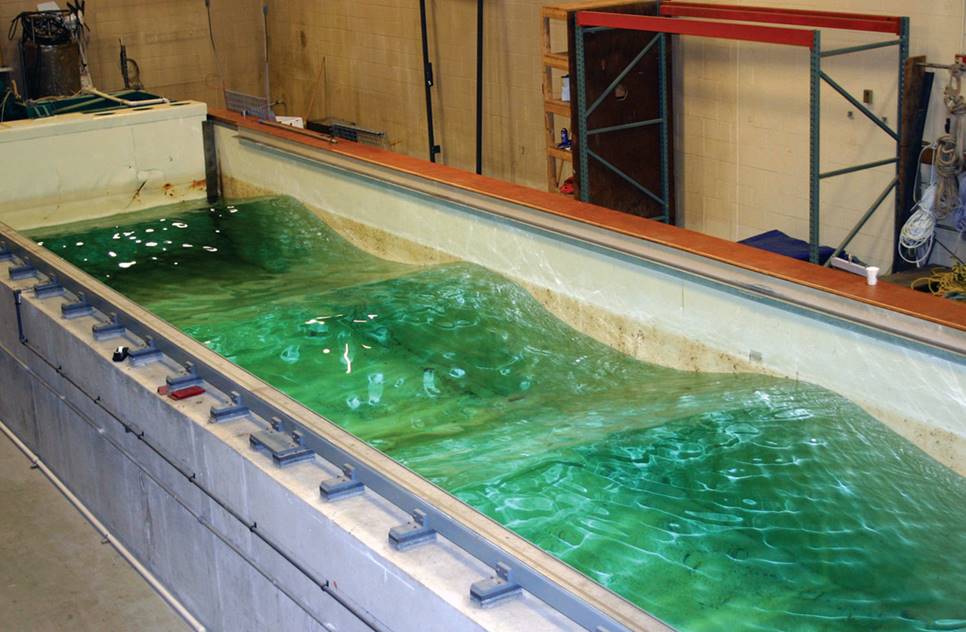

Simulation

As part of the simulation process, the team has planned to

use Dr. Yang’s water tank at the Machine Shop located in the Brownsville

campus. The water tank will provide a similar environment as the one that we

are seeking to use the AUV at, since it provides artificially generated waves

that will help us show how the damper turns the kinetic energy into power. This

mechanism has proved to properly function when assembling in NX 12, but we will

ensure that this is possible through multiple tests in the water tank once the

assembly of the AUV concludes.

FMEA:

Failure Modes and Effects Analysis

|

|

|

|

|

FAILURE MODE AND EFFECTS ANALYSIS |

|

|

|

|

|||||||

|

Item: |

AUV |

Responsibility: |

Team 8 |

|

FMEA number: |

N/A |

|||||||||

|

Model: |

Model 1 |

Prepared by: |

Team 8 |

|

Page : |

N/A |

|||||||||

|

Core Team: |

SDII |

|

FMEA Date (Orig): |

9/16/2021 |

Rev: |

1 |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Process Function |

Potential Failure Mode |

Potential Effect(s) of Failure |

Sev |

Potential Cause(s)/ Mechanism(s) of Failure |

Occur |

Current |

Detec |

RPN |

Recommended Action(s) |

Responsibility and Target Completion Date |

Action Results |

||||

|

Actions Taken |

Sev |

Occ |

Det |

RPN |

|||||||||||

|

Housing of AUV |

Leakage |

The vehicle will sink and therefore stop working. |

10 |

If the housing gets damaged while shipping or in the assembly processes. |

6 |

Assemble an O-ring, made out of rubber. Two aluminum parts will be mounted on either end of the AUV using the appropriate screws, sealing the AUV and stopping water from entering. |

8 |

480 |

The assembly of the O-ring, as well as to use safety methods of shipping to the user in order for it to arrive without any damage that can lead to leakage. |

Assembly Engineer / Shipping Method |

Use of High-Strength 7075 Aluminum Rod to avoid easily get damaged |

8 |

6 |

8 |

384 |

|

Magnets to hold battery in place |

Demagnetize the magnet, making the battery to lose its place and stop the process of storing energy. |

Leave the AUV out of power, which can result in it to get lost depending where it is at the moment. |

9 |

If it gets close to a strong magnetic field of opposite polarity the magnets inside can be demagnetize. |

4 |

Give a proper instruction manual, specifying the possible effects of not storing it properly. Also, provide a special case that can neglect outside magnetic fields from affecting the magnets. |

8 |

288 |

Providing the user with an special carrying case that avoids external magnetic fields of opposite polarity. |

Design Engineer |

Development of a detailed instruction manual in order to avoid these issues. As well as to seek materials that can be used as isolating materials in the carrying case the AUV requires. |

8 |

4 |

8 |

256 |

QFD

(Quality Function Deployment)

QFD is a mechanism to ensure that the customer needs drive

the entire product design and production process in the company, including

market planning, product design and engineering, process development and

prototype evaluation, as well as production, sales, and service.

|

Customer Quality Experience |

Design Spec |

Critical Function(s) |

Component(s) |

|

Reliable method for transportation

of material underwater. |

Possibility of creating a cavity to

serve as storage for research material. |

Need to find a way in which at the

time of storing the material we will not let any leakage enter the system. |

Storing space inside AUV housing. |

|

Have an unlimited source of energy,

while at the same time not running out of power. |

Create a renewable source of energy

via a damper mechanism, which will provide energy through the kinetic energy

obtained with the motion of the waves. |

The damper mechanism is custom made

by the team, therefore if we plan to make multiple, we need to make sure all

the measurements are the same because if not this can lead it to not work properly. |

Custom damper mechanism assembled

by team. |

|

Capable of reaching underwater

ground levels, which for people it is hard to achieve due to high pressures. |

Made a design that makes use of

O-rings in the extremes of the AUV in order to avoid

any type of leak due to the high pressure. |

Need to verify that the O-rings fit

the caps properly on both sides of the AUV. |

O-rings. |

Potential Customers

Early on the following AUVs were designated as competitors,

however we then identified them as potential customers due to their limitations

when recharging. All

of these AUVs take up resources by having to be retracted from their

mission to be charged. Our design would

improve all of them.

1. Teledyne Marine

2. RTSYS

3. Tiburon Subsea

4. Kongsberg

Hands on

Analysis

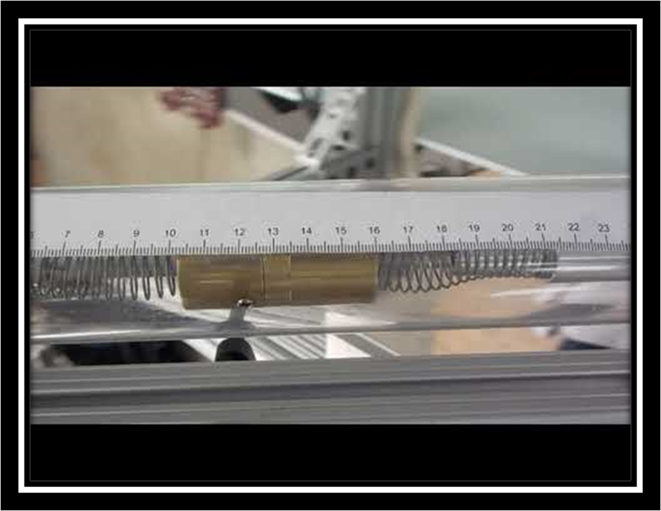

This video illustrates the

oscillation of the mass when subjected to the following parameters: Gear pulse:

6, set point: -7000 to 7000, Velocity: 180 rpm. All tests were done with the AUV

inclined at an angle of 75 degrees to ease the movement of the mass. The ruler is in cm.

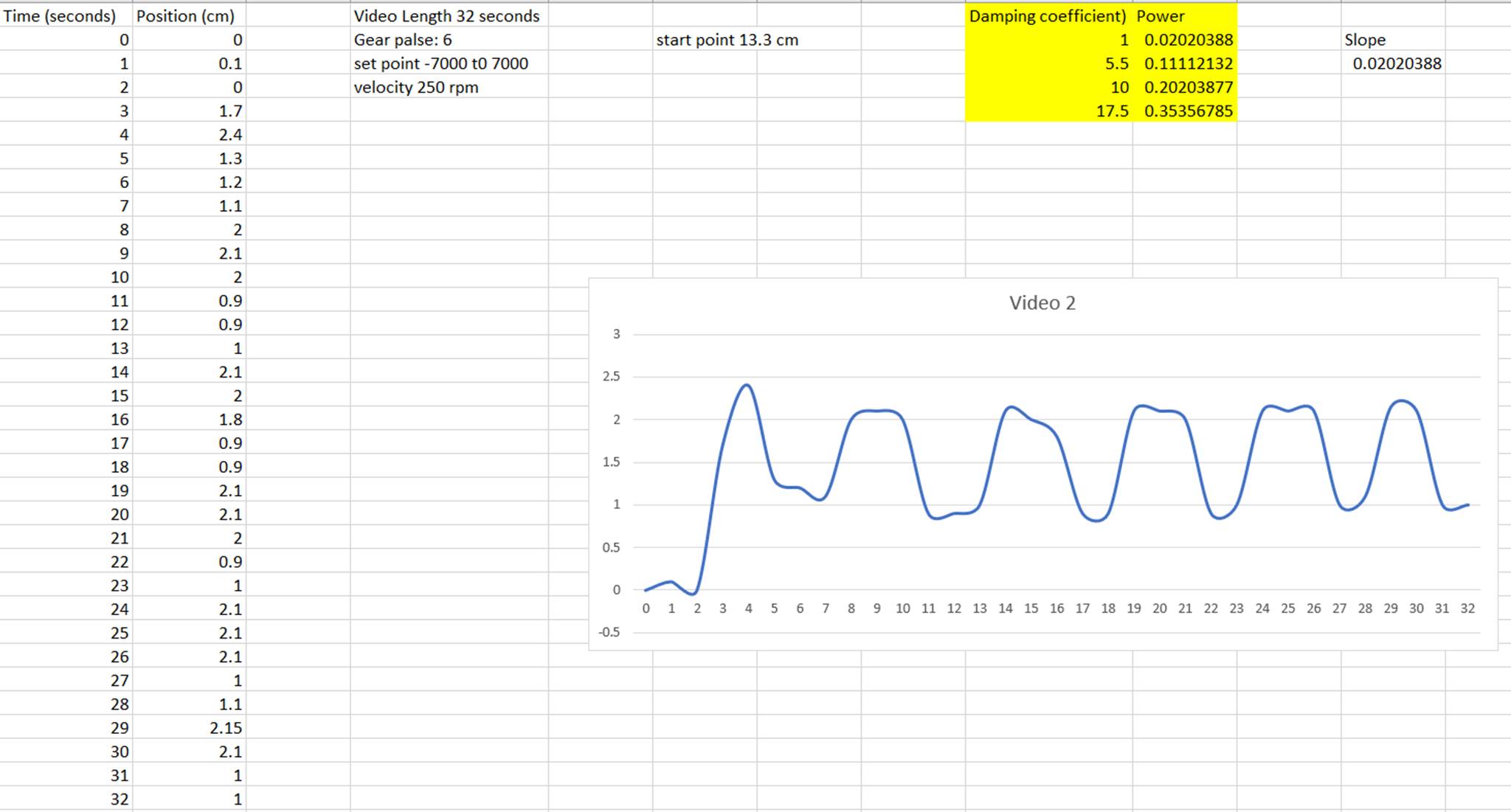

This video illustrates the oscillation

of the mass when subjected to the following parameters: Gear pulse: 6, set

point: -7000 to 7000, Velocity: 250 rpm. All tests were done with the AUV

inclined at an angle of 75 degrees to ease the movement of the mass. The ruler

is in cm.

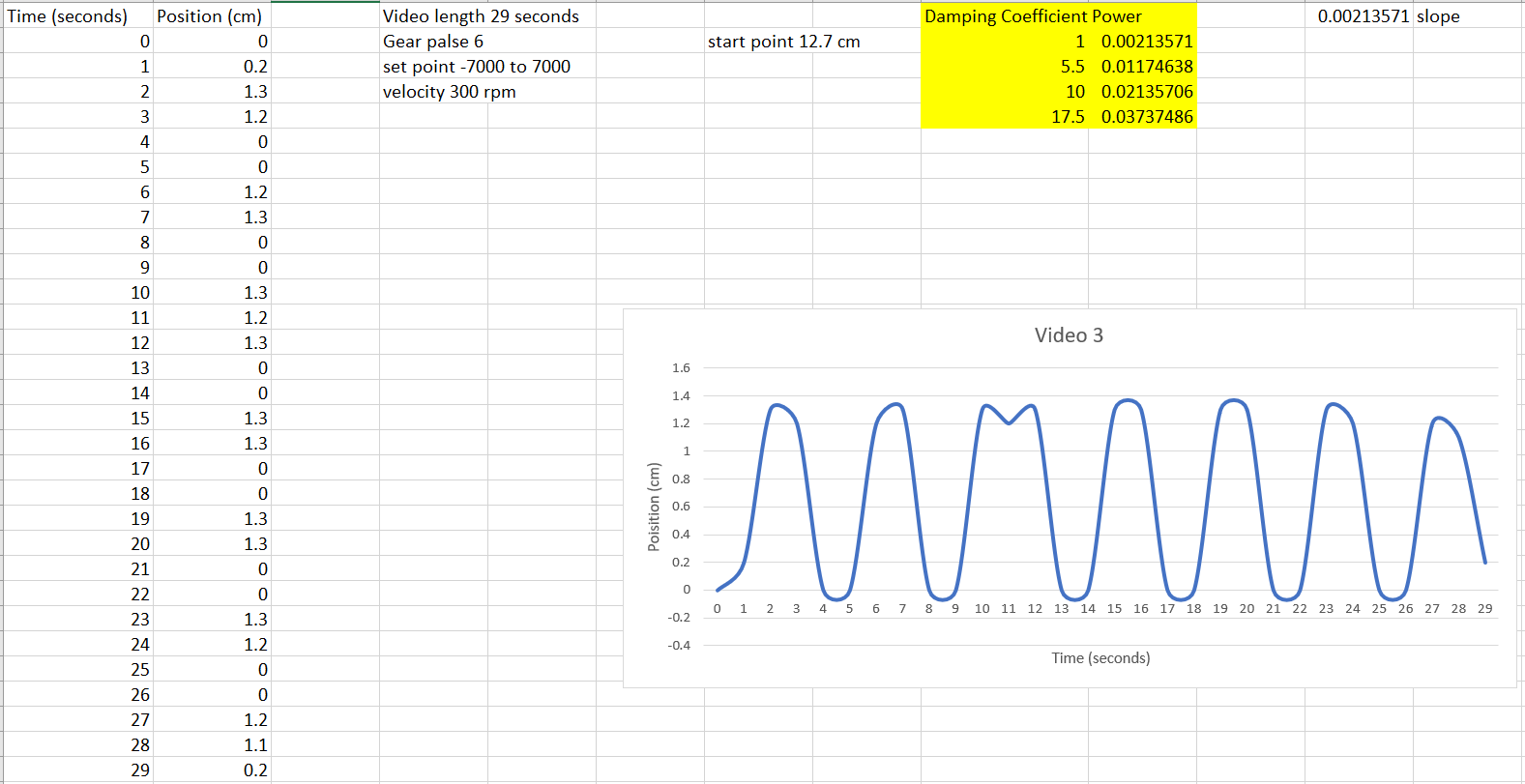

This video illustrates the

oscillation of the mass when subjected to the following parameters: gear pulse: 6, set point: -7000 to

7000, velocity: 300 rpm. All tests were done with the AUV inclined at an angle

of 75 degrees to ease the movement of the mass. The ruler is in cm.

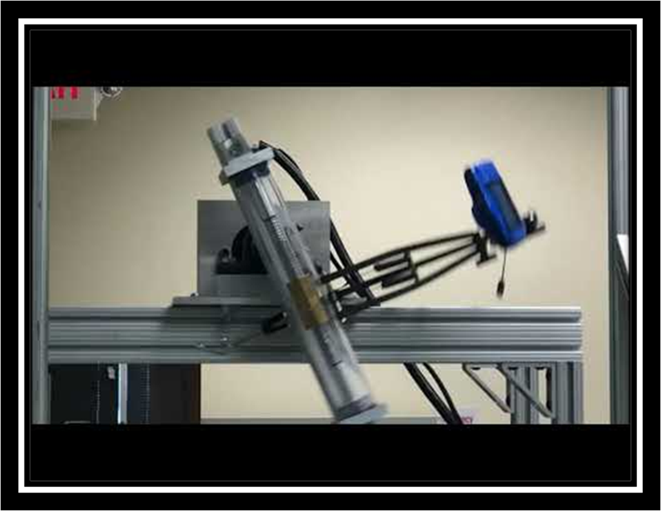

A different view of how the whole

system works. In this video the AUV was subjected to the following parameters: Velocity:

180, Gear pulse: 6, set point 7,000, also

in this view you can observe how the integrated camera system functions to give

a better observation of the mass. Behind it you can also see the motor setup. Giving

a better feel of how the overall system is working.

A different view of how the whole

system works. In this video the AUV was subjected to the following parameters: Velocity:

250, Gear pulse: 6, set point 7,000, also in this view you can observe how the

integrated camera system functions to give a better observation of the mass.

Behind it you can also see the motor setup. Giving a better feel of how the

overall system is working.

A different view of how the whole

system works. In this video the AUV was subjected to the following parameters: Velocity:

360, gear pulse: 6, set point: 7,000, also

in this view you can observe how the integrated camera system functions to give

a better observation of the mass. Behind it you can also see the motor setup.

Giving a better feel of how the overall system is working.

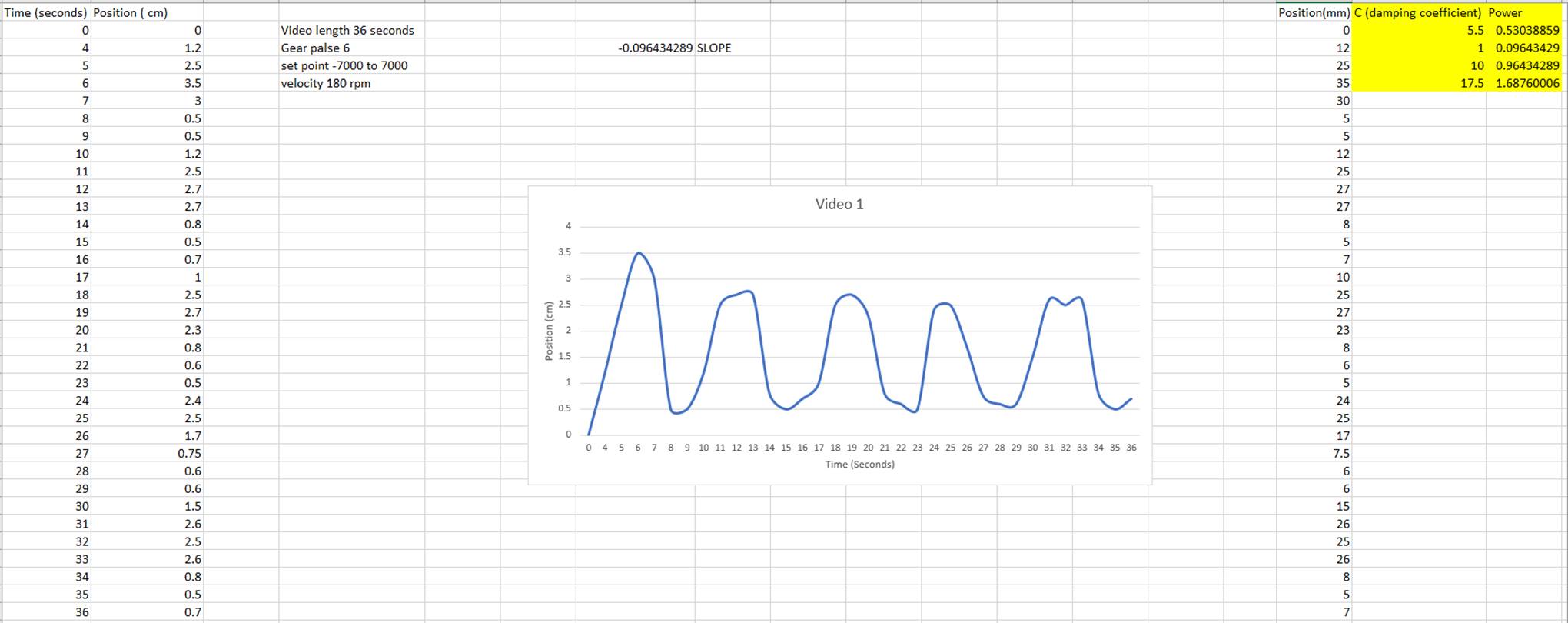

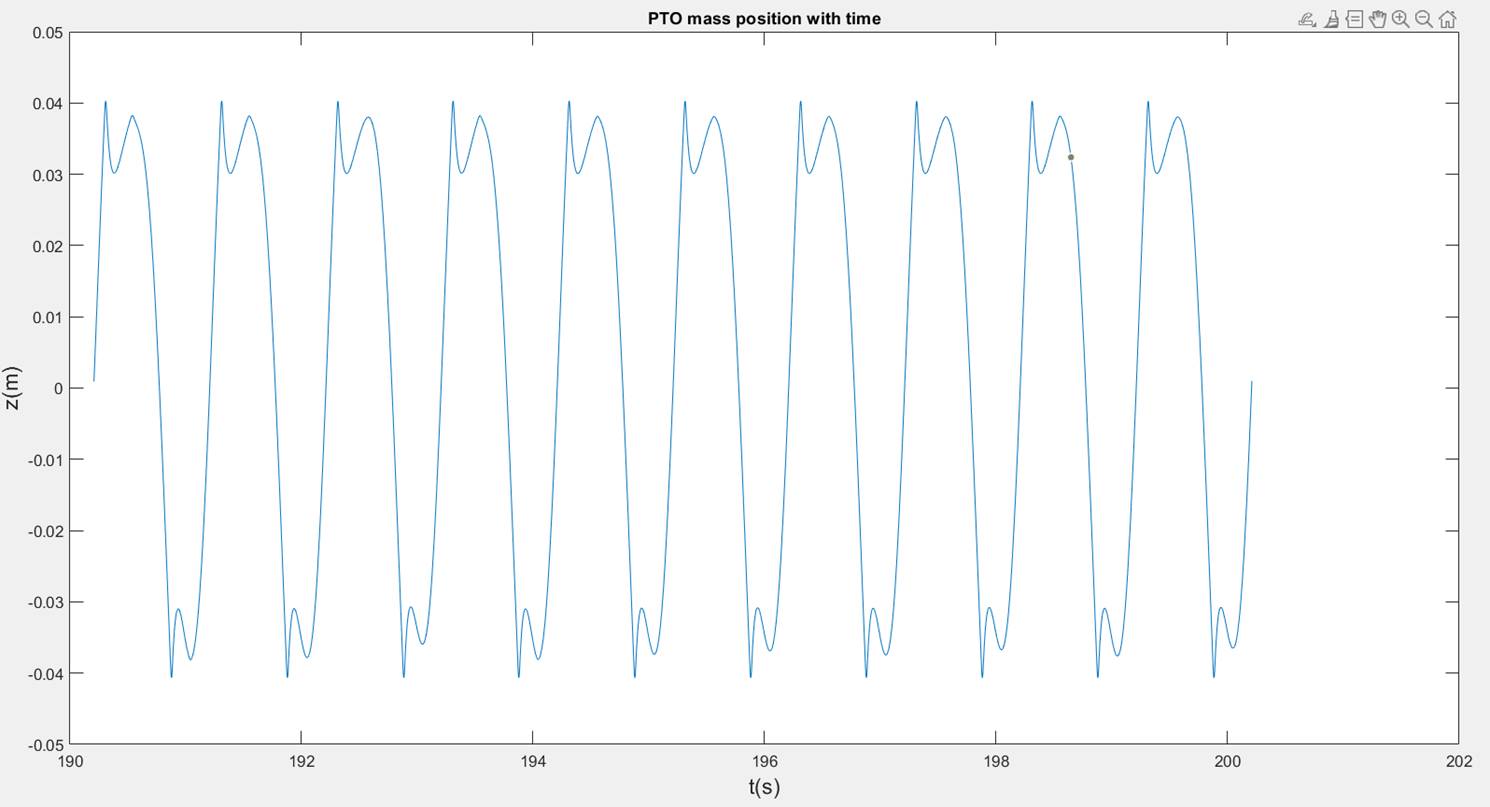

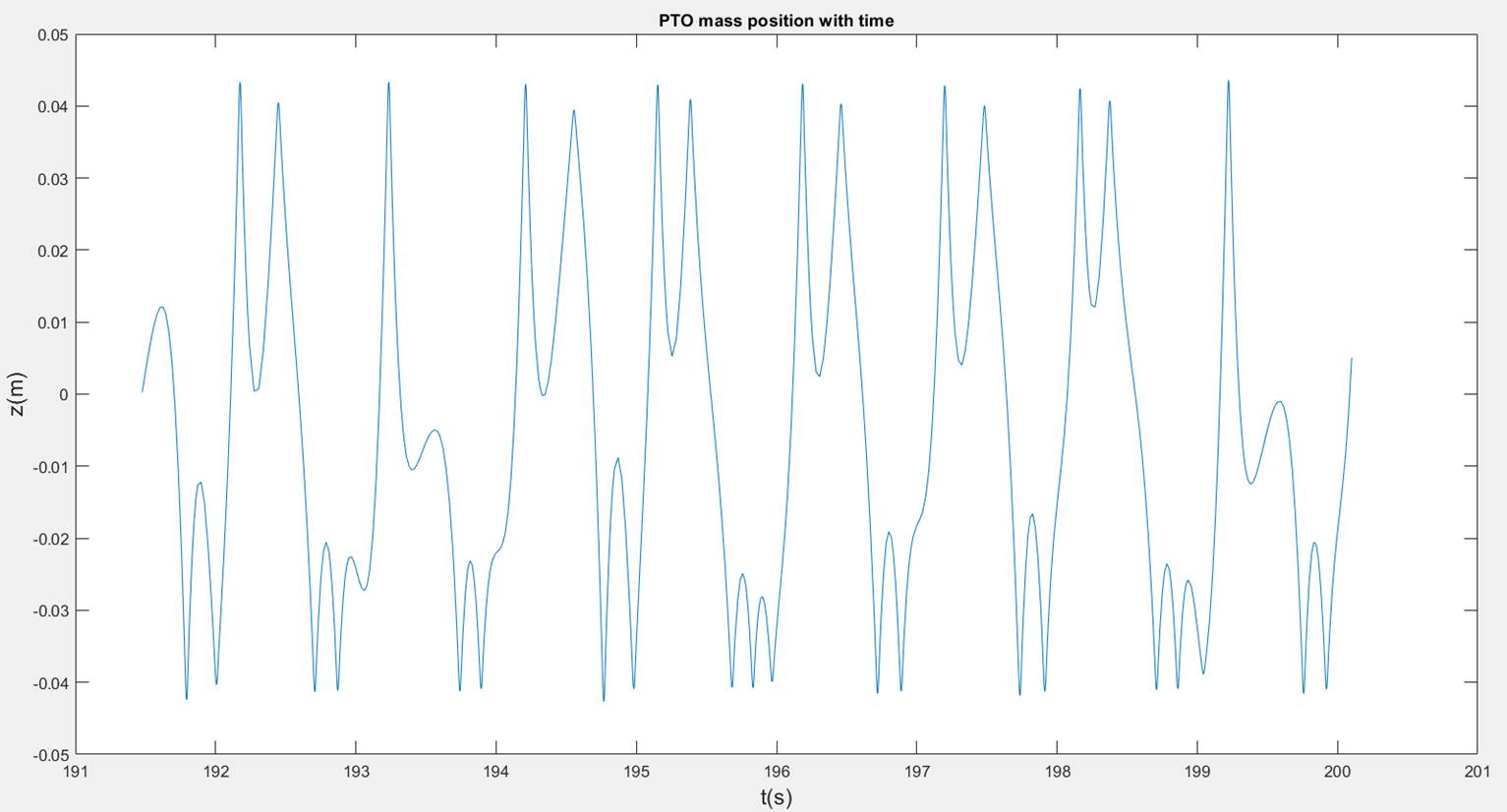

The graph above illustrates the

behavior of the oscillating mass when subjected to conditions of velocity: 180

rpm, gear palse: 6, setpoint: -7000 to 7000. After plotting the graph, we

determined the slope, which is the avg velocity. After obtaining the velocity

we determined the power by using the following formula. Power = damping

coefficient * velocity

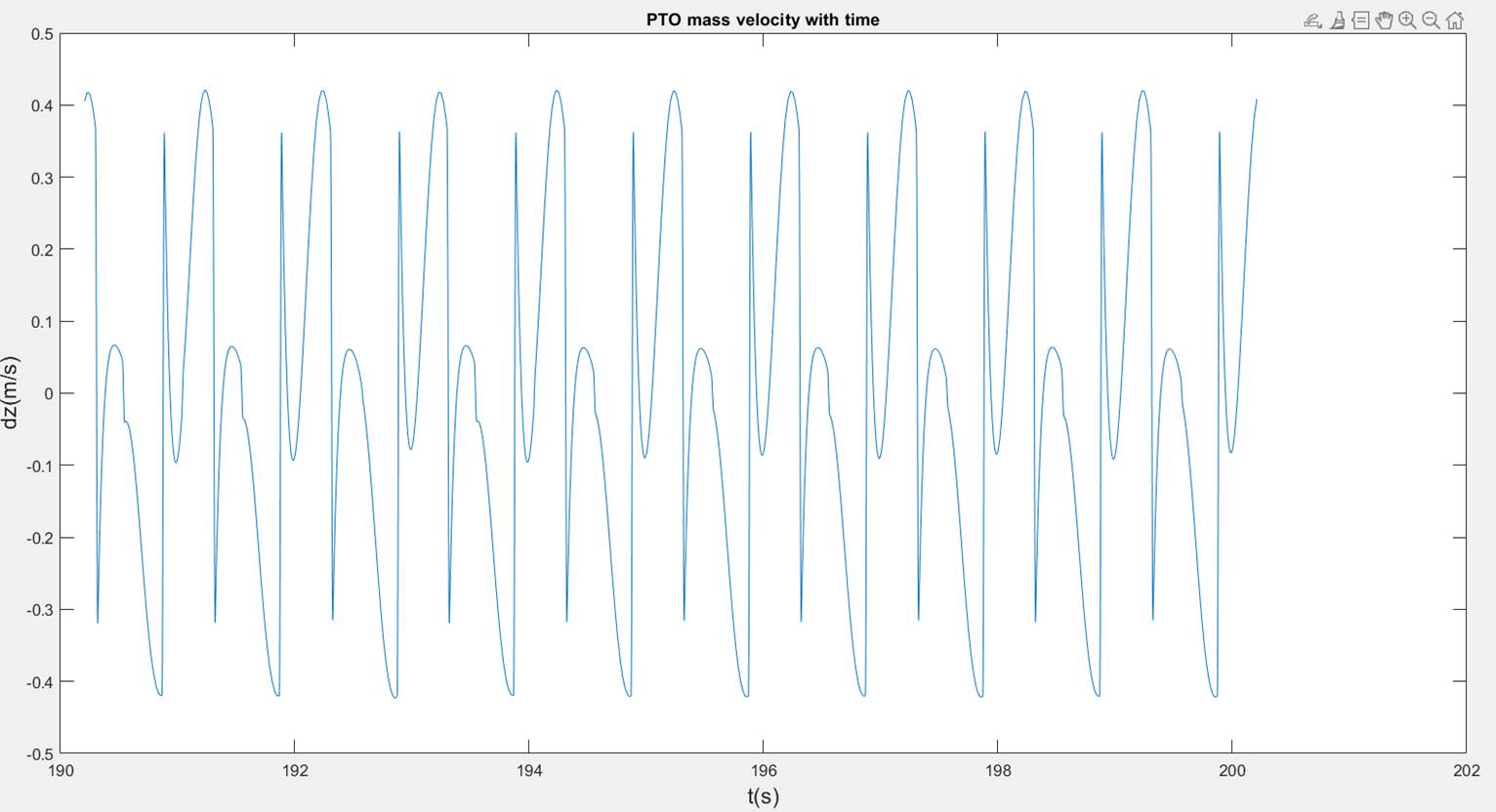

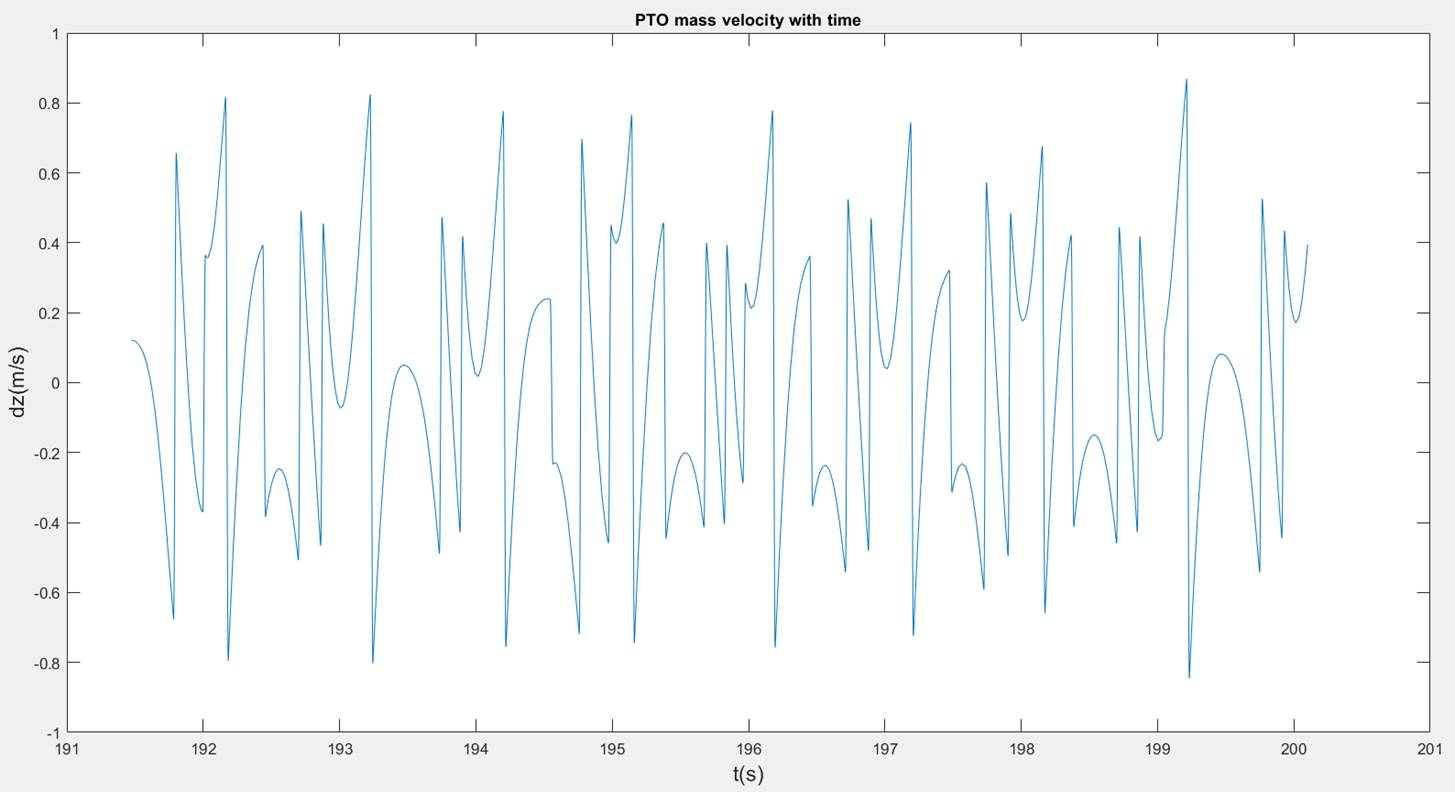

The graph above illustrates the

behavior of the oscillating mass when subjected to conditions of velocity: 250

rpm, gear palse: 6, setpoint: -7000 to 7000. After plotting the graph, we

determined the slope, which is the avg velocity. After obtaining the velocity

we determined the power by using the following formula. Power = damping

coefficient * velocity

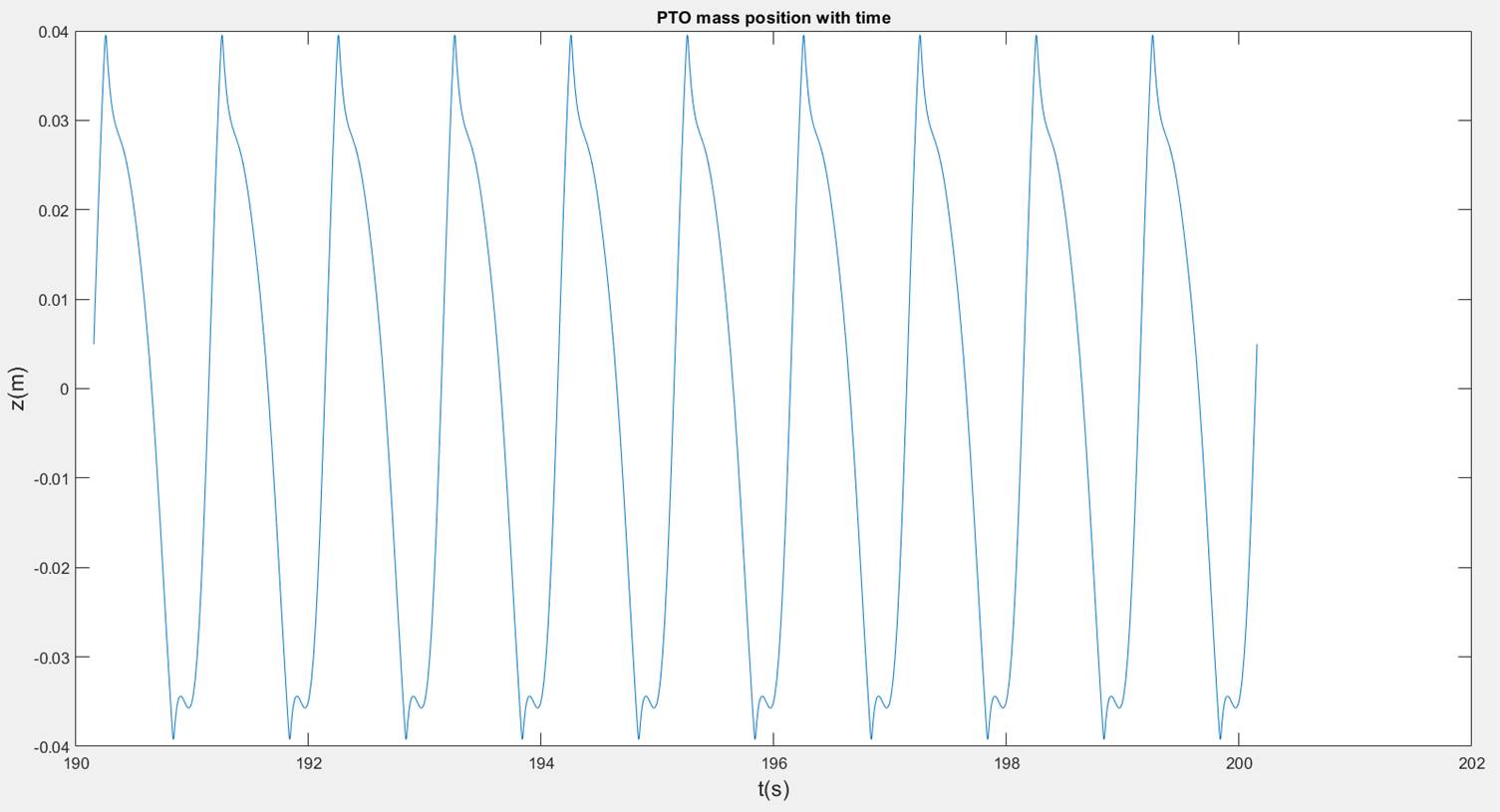

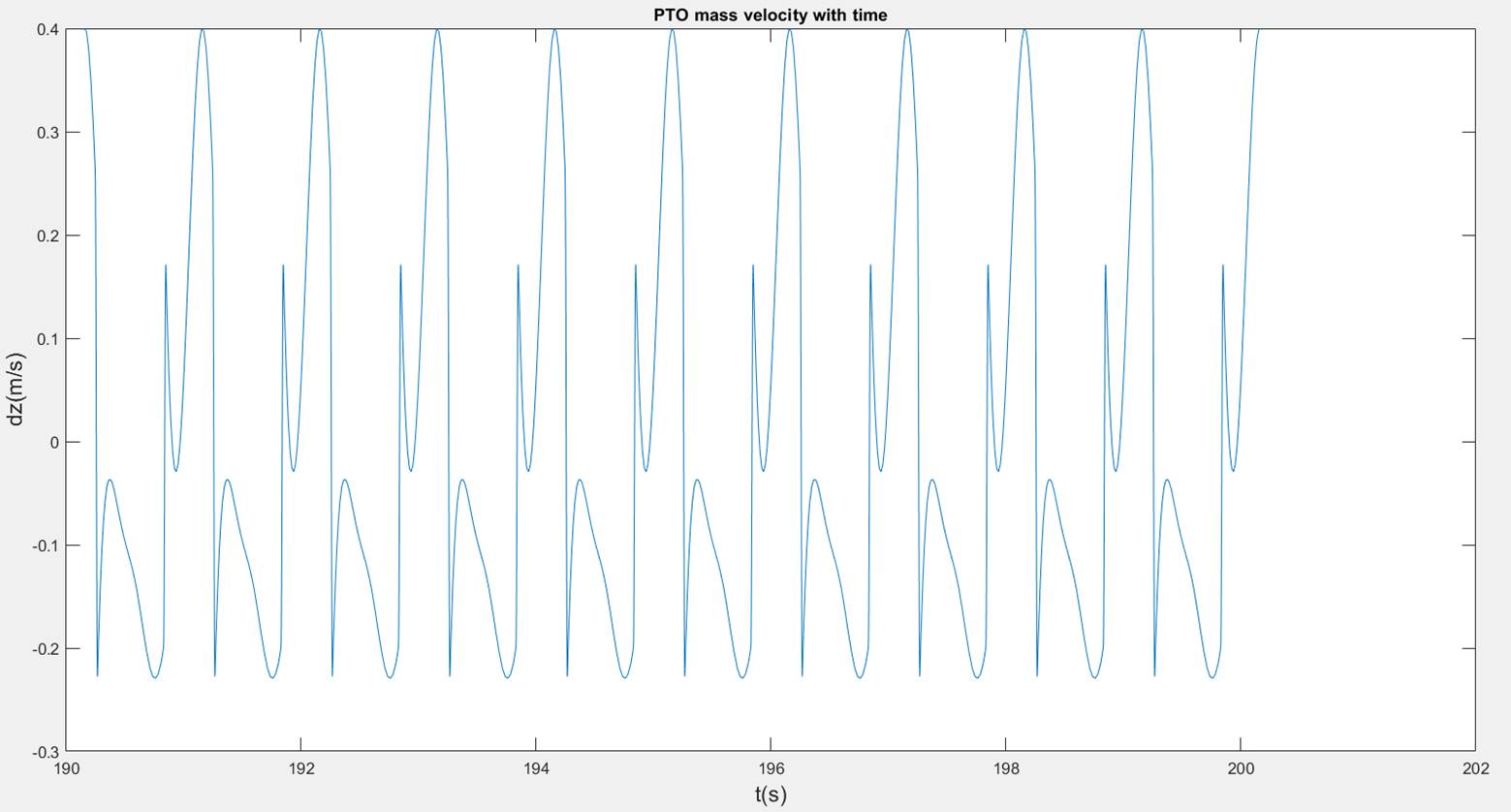

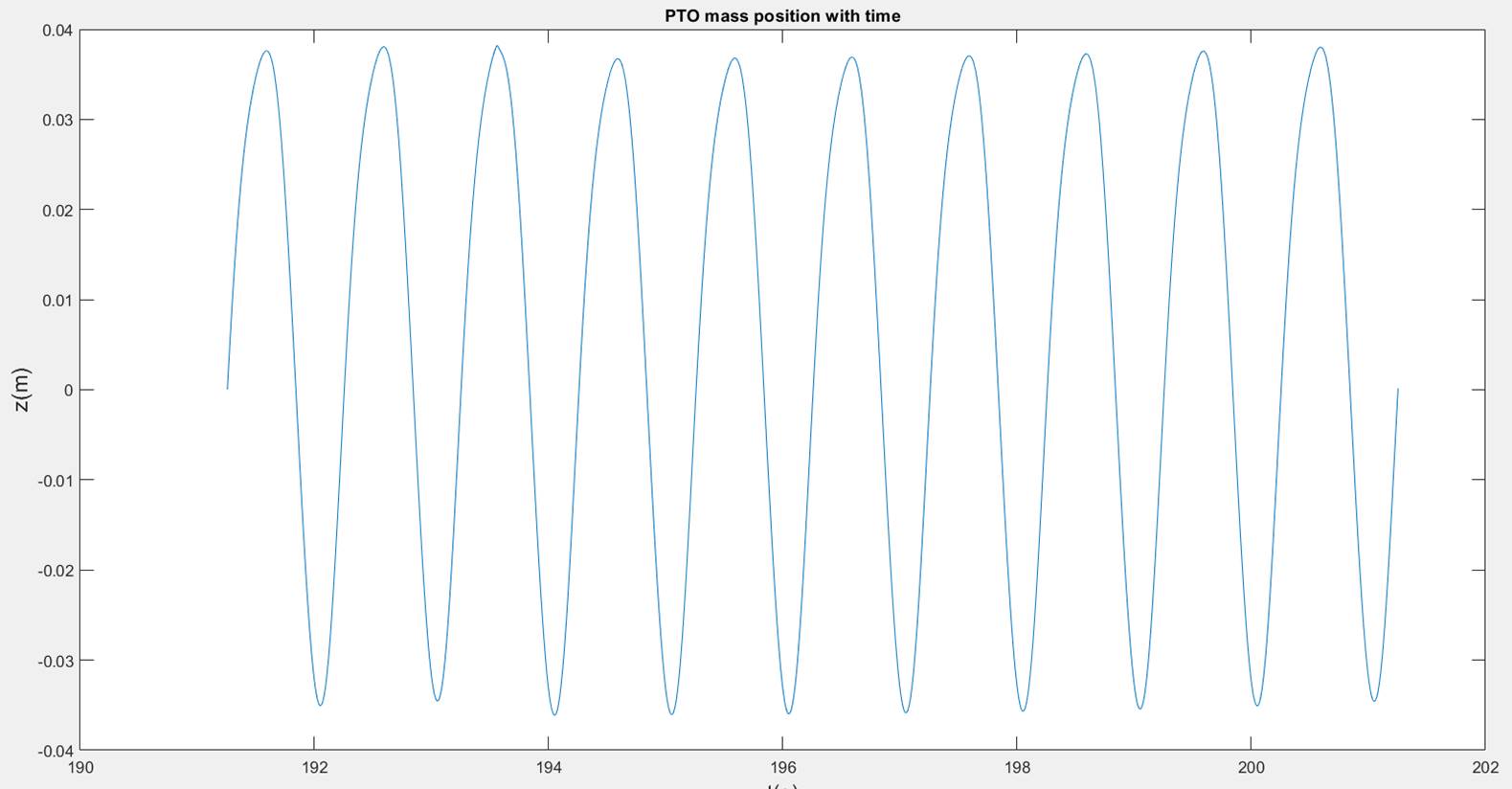

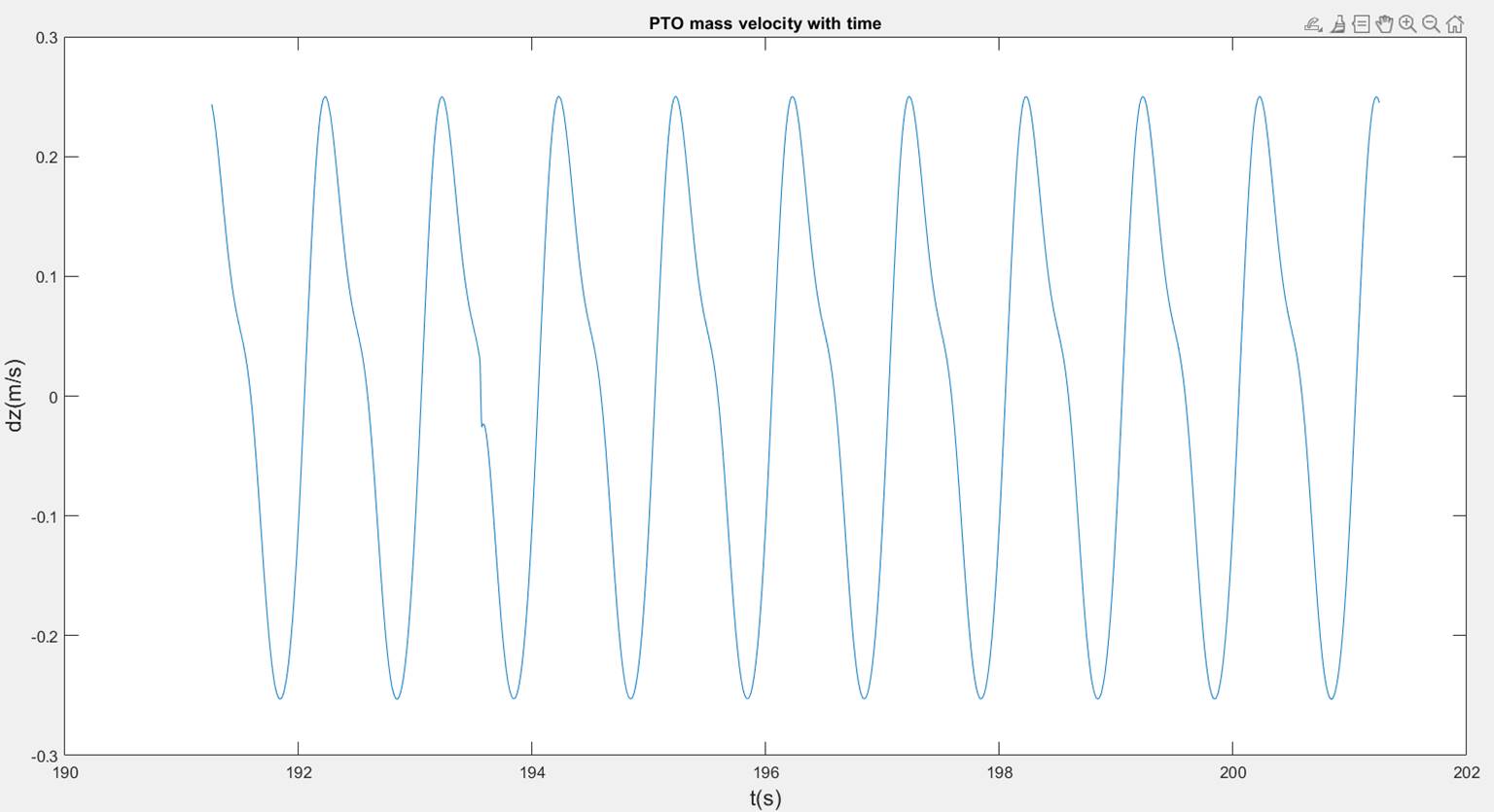

The graph above illustrates the

behavior of the oscillating mass when subjected to conditions of velocity: 300

rpm, gear palse: 6, setpoint: -7000 to 7000. After plotting the graph, we

determined the slope, which is the avg velocity. After obtaining the velocity

we determined the power by using the following formula. Power = damping

coefficient * velocity

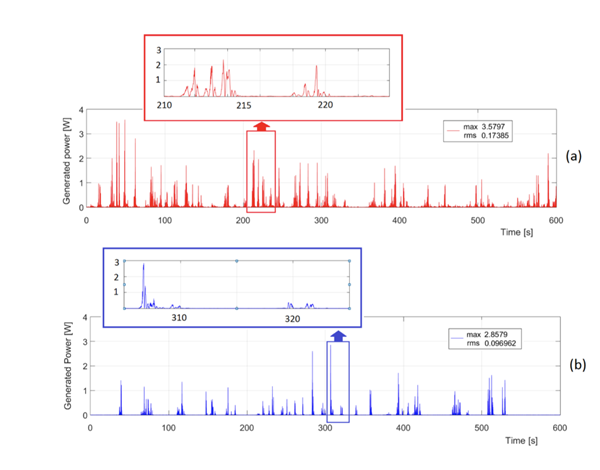

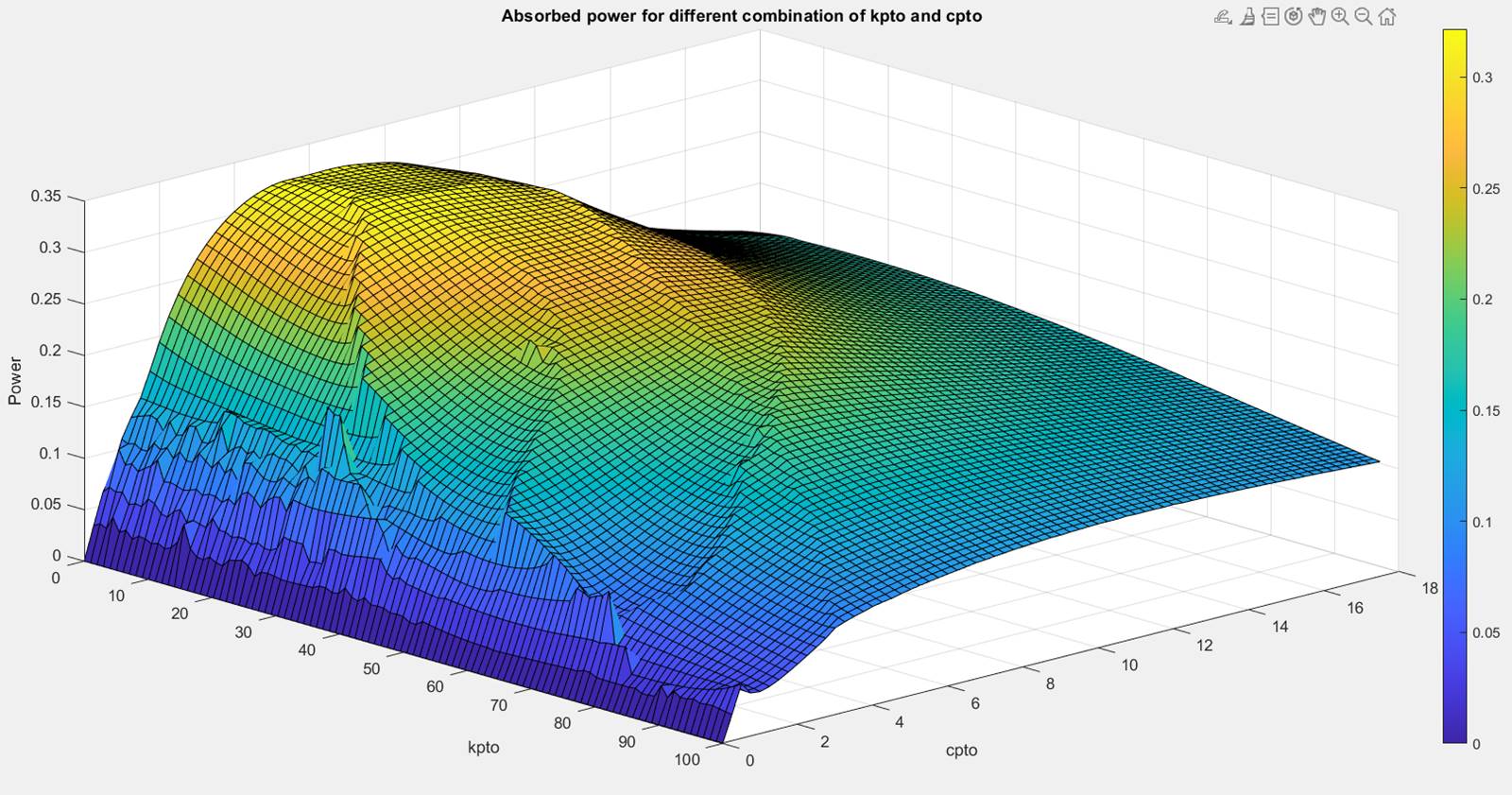

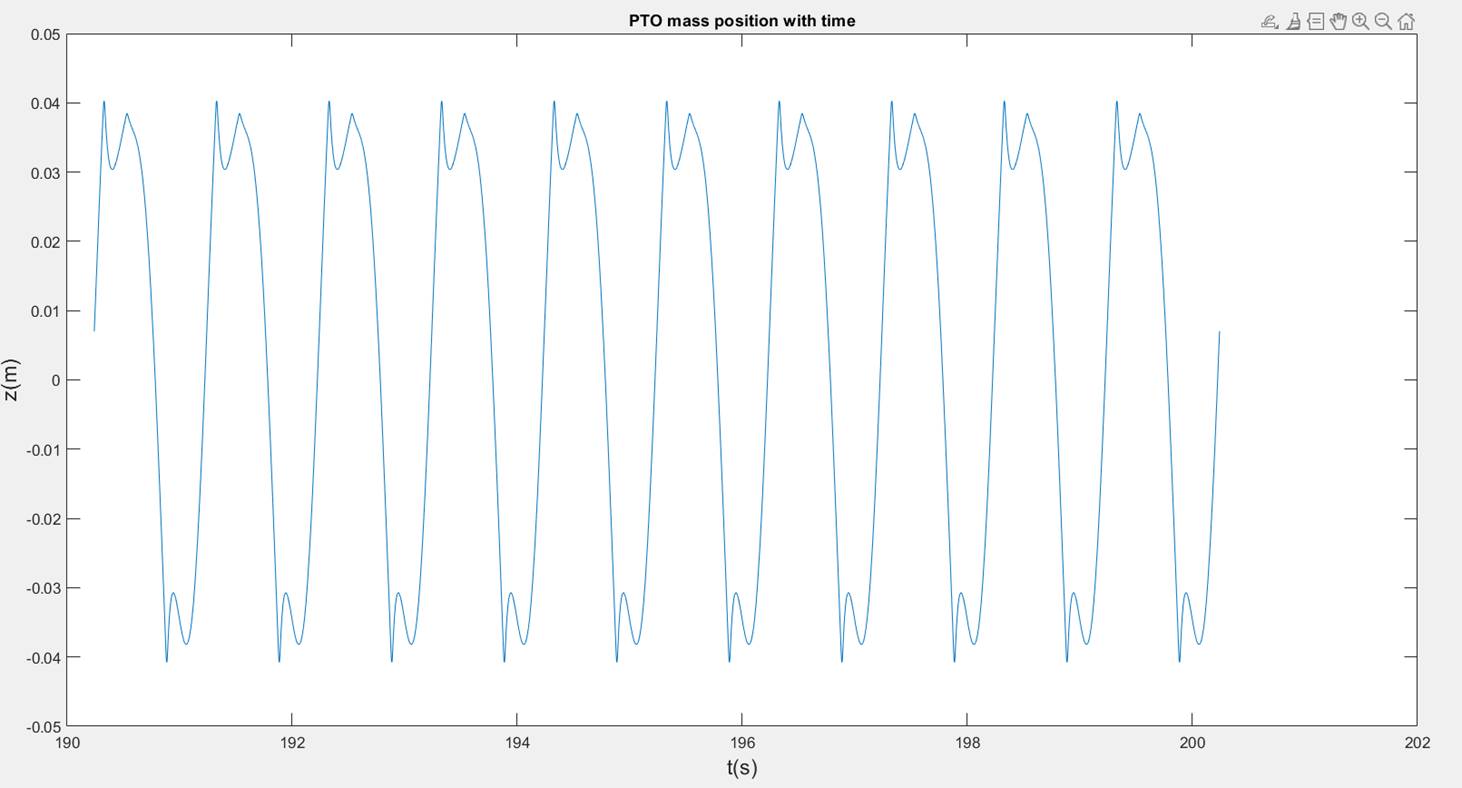

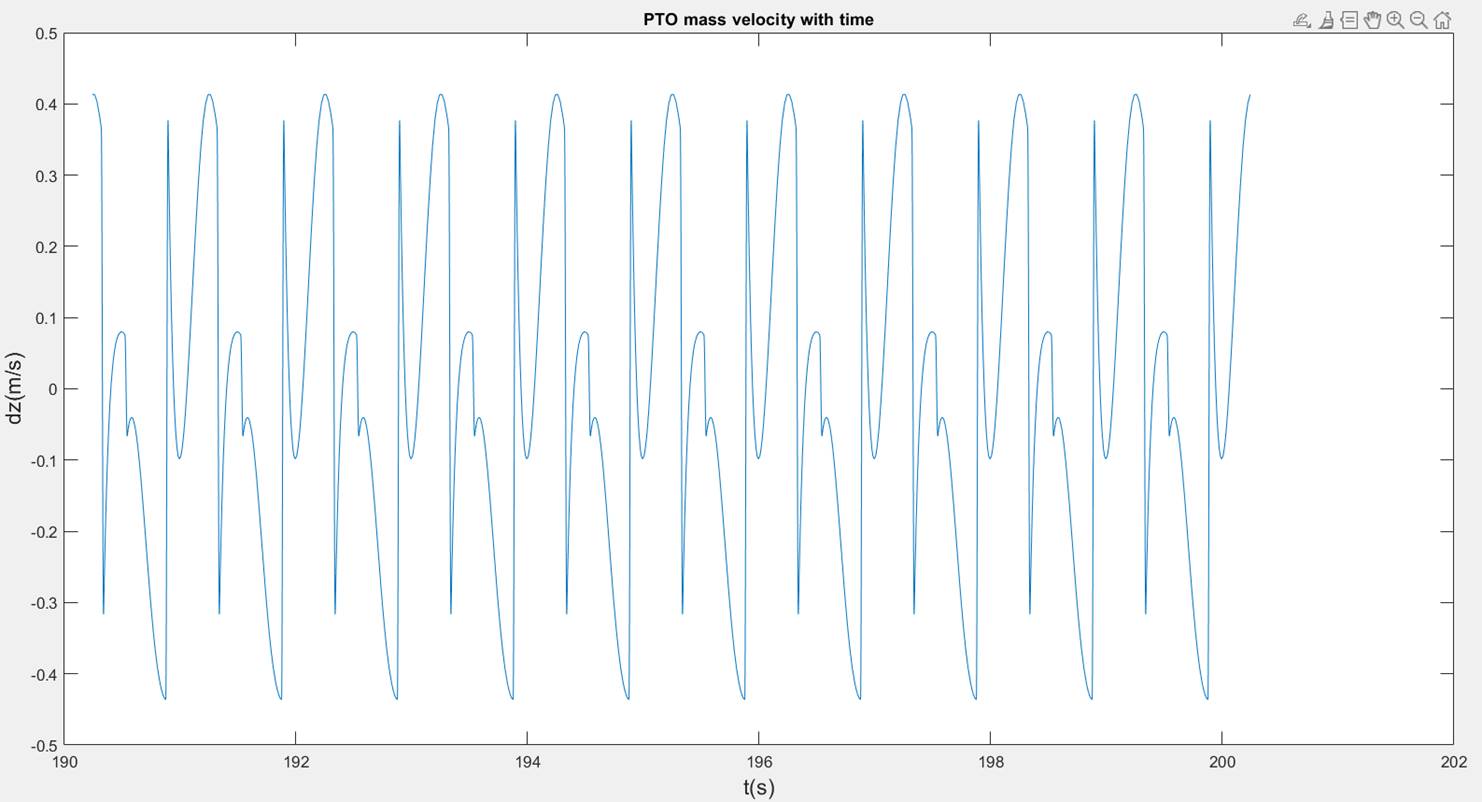

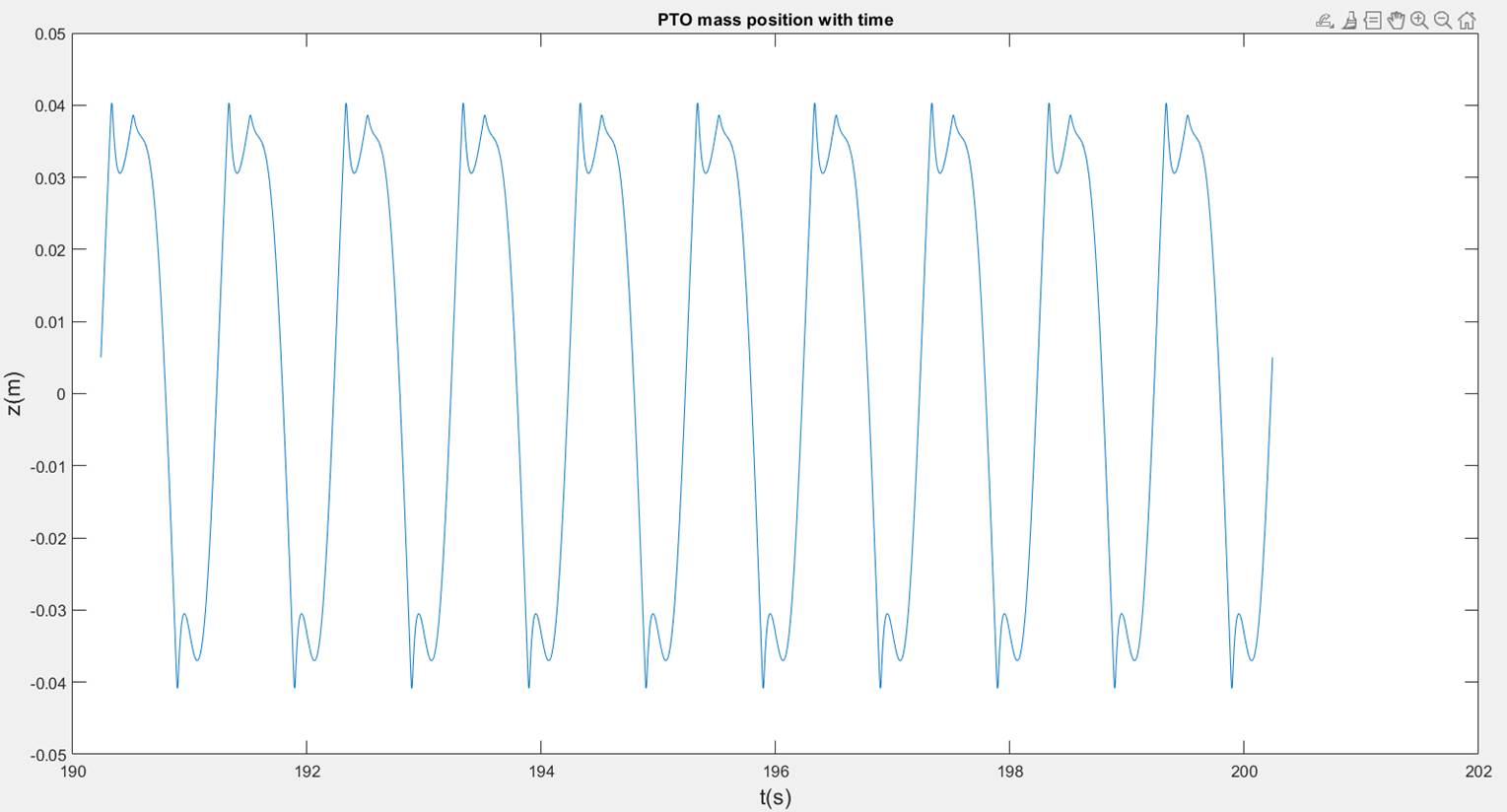

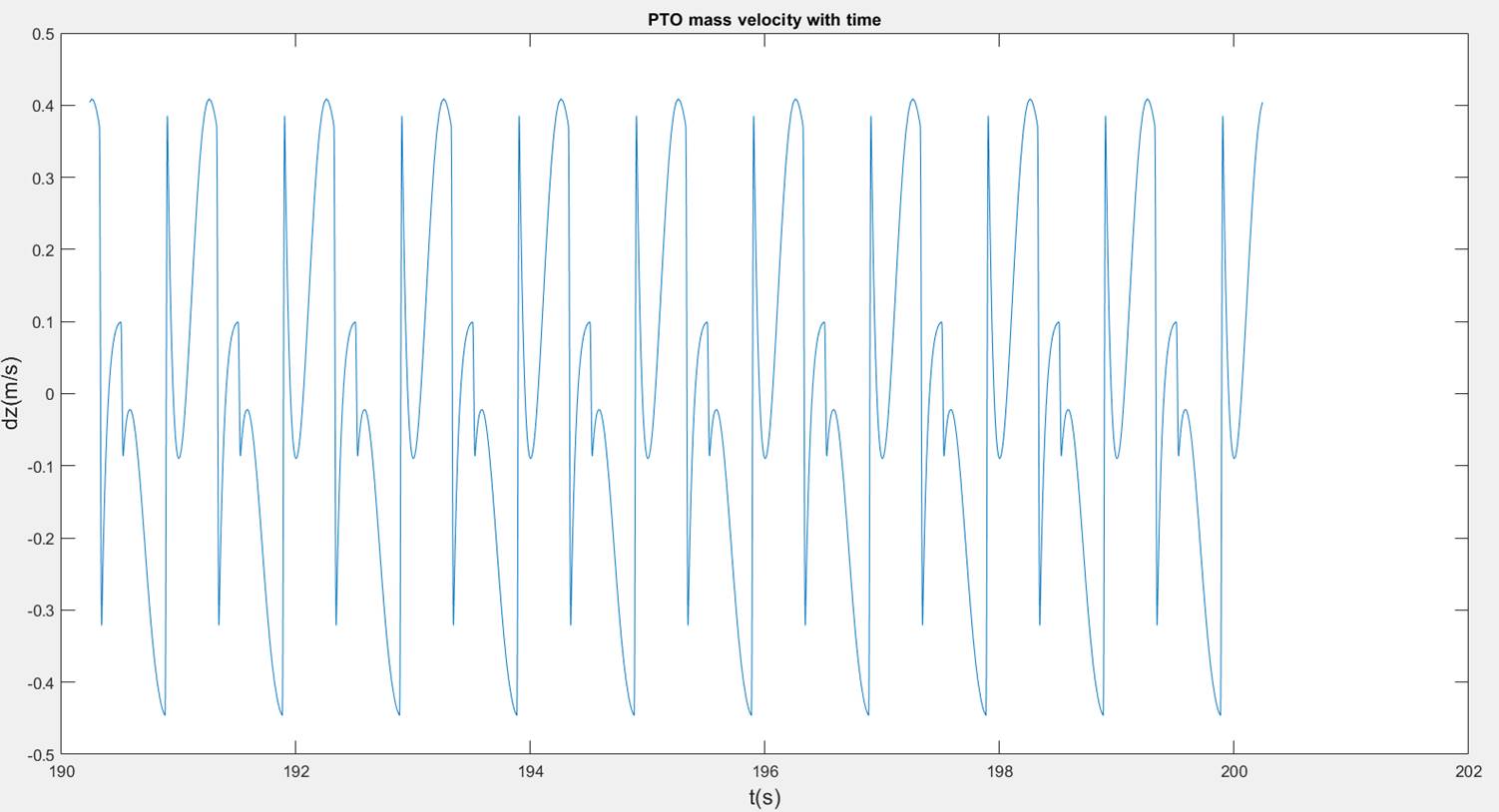

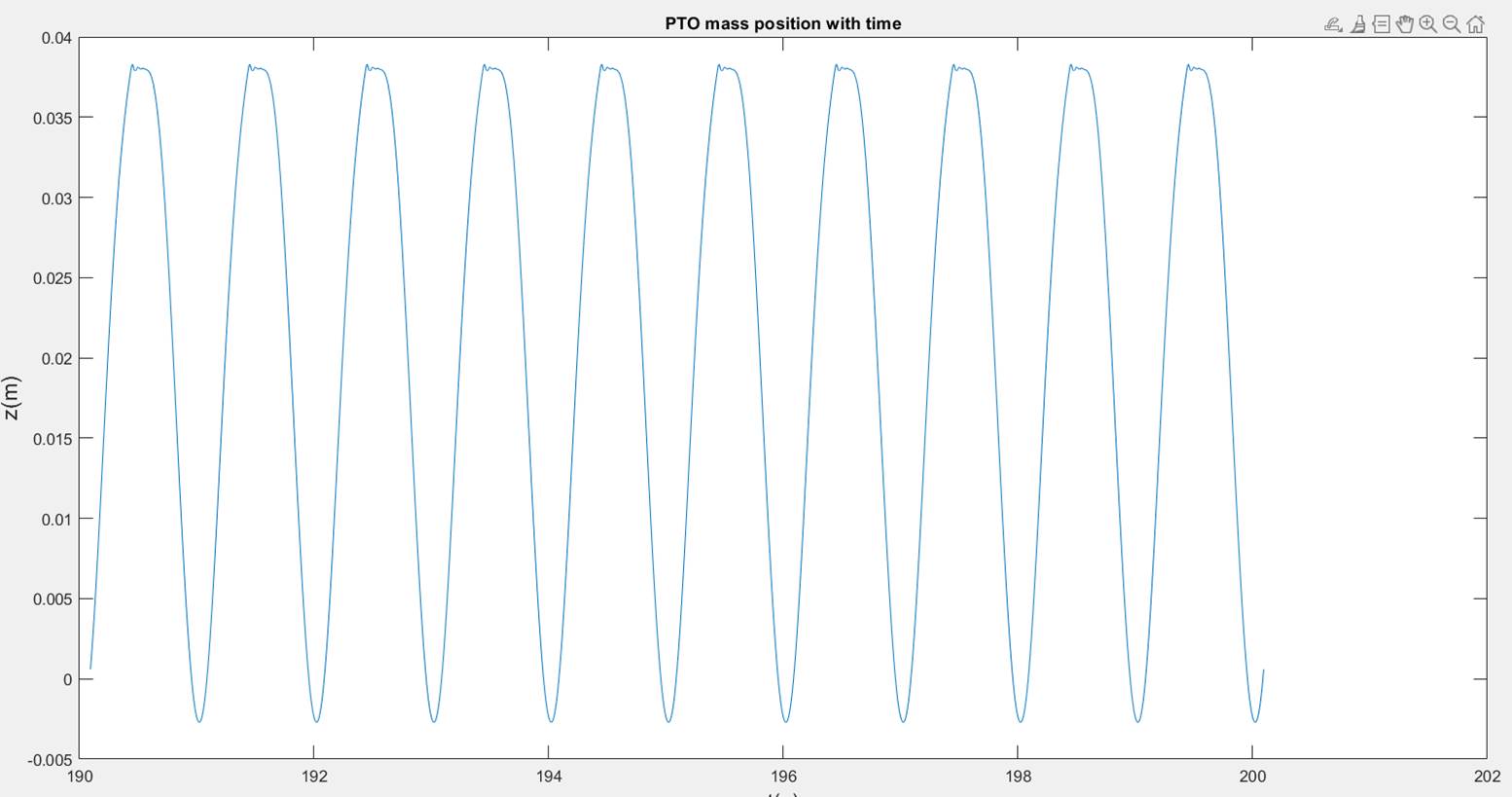

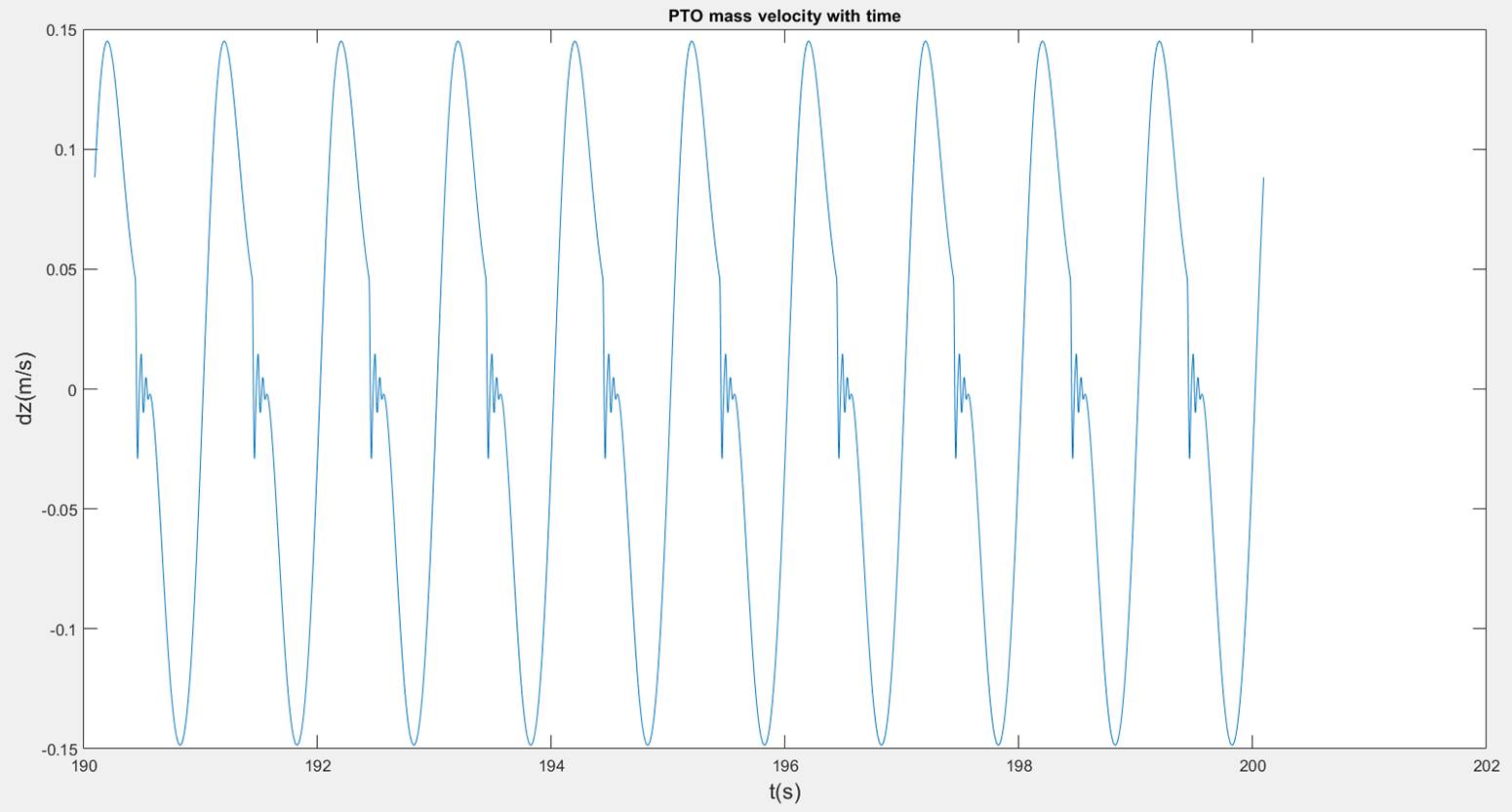

Power and Time Plots for Reduced

Model

Parameters

used:

Gravitational

acceleration, g = 9.81 m/![]() ;

;

Wave

frequency, ![]() = 1 Hz;

= 1 Hz;

Wave height,

H = 0.2 m;

AUV

oscillation amplitude, theta = pi/3;

Phase angle,

phi = 0;

Power

take-off (PTO) mass, m = 0.357 Kg;

PTO mass

stroke, z0 = 0.038 m;

Disk spring

parameter, n = 100;

![]()

Absorbed

power, P = 0.3215 W

![]()

Absorbed

power, P = 0.3201 W

![]()

Absorbed

power, P = 0.3205 W

![]()

Absorbed

power, P = 0.2097 W

![]()

Absorbed

power, P = 0.1115 W

![]()

Absorbed

power, P = 0.2775 W

![]() Ns/m

Ns/m

Absorbed

power, P = 0.1629 W

As you can see there is a deviation

between the experimental and mathematical model results. We believe the reason

for this is the quality of the camera. Due to budget issues, we utilized a

provided camera not equipped with the frame rate technology to analyze every

0.1 second. Either that or the video viewing software we used did not support

its capabilities. This is something to keep in mind in the future when other

senior design groups continue this work.

The objective

of the Testing and Validation stage is to prove our theories and methodologies in order to see if they work as intended, as well as to make

the necessary adjustments in order to achieve the most efficient AUV results.

This stage of the project Is currently a work in progress.

1. “Autonomous

Underwater Vehicle (AUV) Market,” Market Research Firm. [Online].

Available: https://www.marketsandmarkets.com/Market-Reports/autonomous-underwater-vehicles-market-141855626.html. [Accessed:

28-Jan-2021].

2. “Autonomous

Underwater Vehicle Manufacturers (AUV, UUV, ROV),” Unmanned Systems

Technology. [Online]. Available: https://www.unmannedsystemstechnology.com/category/supplier-directory/platforms/uuv-manufacturers/. [Accessed:

28-Jan-2021].

3. “Autonomous

underwater vehicles,” MBARI, 23-May-2018. [Online].

Available: https://www.mbari.org/at-sea/vehicles/autonomous-underwater-vehicles/. [Accessed:

28-Jan-2021].

4. “Comet-300

AUV,” RTSYS, 13-Jan-2021. [Online]. Available: https://rtsys.eu/comet-300-auv. [Accessed:

28-Jan-2021].

5. “SEARAPTOR

AUV,” ProductPage. [Online].

Available: http://www.teledynemarine.com/searaptor-auv?ProductLineID=15. [Accessed:

28-Jan-2021].

6. T. Baoqiang and J. Yu, “Current status and prospects of

marine renewable energy applied in ocean robots,” International Journal

of Energy Research, vol. 43, no. 6, pp. 2016–2031, Jan. 2019.

7. Bellingham,

J. (2009). Platforms: Autonomous underwater vehicles. Encyclopedia of

Ocean Sciences, 159-169. doi:10.1016/b978-0-12-813081-0.00730-8

8. http://web.mit.edu/12.000/www/m2005/a2/finalwebsite/equipment/robotics/structure.shtml

9. A. M.

Bradley, M. D. Feezor, H. Singh, and F. Y. Sorrell,

“Power Systems for Autonomous Underwater Vehiclesa,” IEEE

JOURNAL OF OCEANIC ENGINEERING, vol. 26, no. 4, pp. 526–536, Oct. 2001.

10. Author Logan

Mock-Bunting. (2015, November 25). The many challenges of underwater

communication. Retrieved February 25, 2021, from https://schmidtocean.org/cruise-log-post/the-many-challenges-of-underwater-communication/

11. Mange, V.,

Shah, P., & Kothari, V. (2019, June). Autonomous underwater vehicle:

Electronics and software ... Retrieved February 25, 2021, from https://www.irjet.net/archives/V6/i6/IRJET-V6I6689.pdf

12. Ewachiw, M. A., Jr.

(2014, June). Design of an autonomous underwater vehicle (auv)

charging ... Retrieved February 25, 2021, from https://apps.dtic.mil/dtic/tr/fulltext/u2/a610285.pdf

13. ROV FAQs.

(2021, January 28). Retrieved February 25, 2021, from https://schmidtocean.org/education/rov-faqs/

14. Ashish. “How

Does A Submarine Dive,

Resurface And Navigate Underwater? " Science ABC.” Science

ABC, 3 Dec. 2019, www.scienceabc.com/innovation/how-does-a-submarine-dive-resurface-and-navigate-underwater.html.

15. Hyakudome, Tadahiro. “Design of Autonomous Underwater Vehicle - Tadahiro Hyakudome,

2011.” SAGE Journals, journals.sagepub.com/doi/10.5772/10536.

16. Yun Hae Kim, Young Dae Jo, Sung Youl Bae and Seok Jin Sin,

"Material design of Al/CFRP hybrid composites for the hull of autonomous

underwater vehicle," OCEANS'10 IEEE SYDNEY, Sydney, NSW, Australia, 2010,

pp. 1-5, doi: 10.1109/OCEANSSYD.2010.5603587.

17. Structure.

[Online]. Available: http://web.mit.edu/12.000/www/m2005/a2/finalwebsite/equipment/robotics/structure.shtml.

[Accessed: 09-Mar-2021].

18. E.

Delory and J. Pearlman, Eds., “Chapter 5 - Innovative

Sensor Carriers for Cost-Effective Global Ocean Sampling,” in Challenges

and Innovations in Ocean In Situ Sensors,

Elsevier, pp. 173–288.

19. Author

Logan Mock-Bunting, “The Many Challenges of Underwater Communication,” Schmidt

Ocean Institute, 25-Nov-2015. [Online]. Available: https://schmidtocean.org/cruise-log-post/the-many-challenges-of-underwater-communication/.

[Accessed: 09-Mar-2021].

20. “AUV

LAB – ODYSSEY CLASS HISTORY,” MIT Sea Grant. [Online].

Available: https://seagrant.mit.edu/auv-odyssey-class/.

[Accessed: 09-Mar-2021].

21. “Is

Lithium-ion the Ideal Battery?,” Advantages

& Limitations of the Lithium-ion Battery - Battery University.

[Online]. Available: https://batteryuniversity.com/learn/archive/is_lithium_ion_the_ideal_battery.

[Accessed: 09-Mar-2021].

22. F.

Aguirre, S. Vargas, D. Valdes, and J. Tornero, “State

of the Art of Parameters for Mechanical Design of an Autonomous Underwater

Vehicle,” International Journal of Oceans and Oceanography , vol. 11, no. 1, pp. 89–103,

2017.

23. Yang, Y.,

2021, ‘Weekly Faculty Advisor Meetings’

24. N.

Townsend, “In situ results from a new energy scavenging system for an

autonomous underwater vehicle,” OCEANS 2016 MTS/IEEE Monterey, 2016.

This is a summary of important Senior

Design files, click on each to open in a different window.

SDI

REVIEWS

R2

RN

MIDTERM

PRESENTATION

FINAL

PRESENTATION

REPORT

SDII

REVIEWS

R1

R2

RN

MIDTERM

PRESENTATION

FINAL

THIS WEBSITE